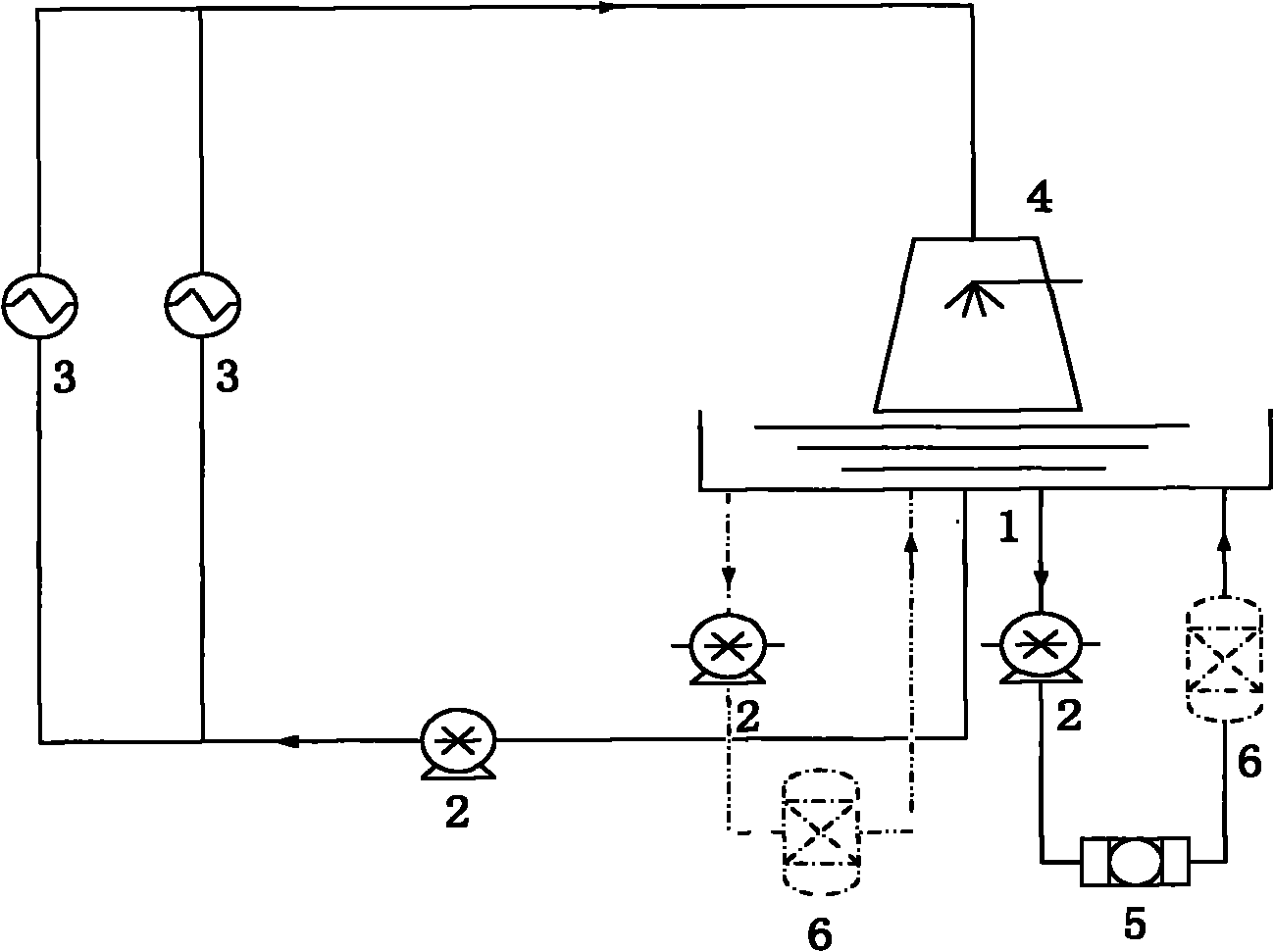

Recirculated cooling water system and purification method for recirculated cooling water

A technology of circulating cooling water and circulating water, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long pretreatment process, difficult equipment maintenance, and shortened membrane life etc. to achieve the effects of low operating costs, energy saving, and less bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example shows that the present invention can purify the circulating water to different degrees through the biological aerated filter with adjustable hydraulic retention time, and the sewage of the circulating water can be discharged directly.

[0024] The circulating water volume of the circulating cooling system of a petrochemical refinery in China is 8700m 3 / h, the existing side filter capacity is 300m 3 / h, for the purpose of saving water and reducing emissions, the recycled water was reused from sewage. When the biological aeration filter is not installed, the water quality data of the circulating water is CODcr 80mg / L, BOD 5 10mg / L, ammonia nitrogen 2mg / L, turbidity 30mg / L. At this time, because the indicators of circulating water cannot meet the discharge standard of CODcr<60mg / L, the circulating water must be treated in the sewage treatment plant before being discharged after reaching the standard, which greatly increases the load of the sewage treatment ...

Embodiment 2

[0027] This example shows that the present invention can carry out biochemical treatment on the leaked pollutants without extensive discharge and supplementation. Combining with Example 1, it is illustrated that the present invention can prevent and treat the deterioration of circulating water quality due to material leakage, circulating water for sewage reuse and other reasons.

[0028] The device situation is the same as in Example 1, and the residence time is 1.5h. One day, a material leak occurred in the circulating water system, and the leaking heat exchanger was found within 36 hours and plugged. The leaked material was light diesel oil. The water quality data of circulating water during normal production is CODcr 40mg / L, ammonia nitrogen 0.1mg / L, and turbidity 8mg / L. The water quality analysis data monitored since the leakage was found are shown in Table 1.

[0029] Table 1

[0030] time

[0031] As can be seen from Table 1, the biological aerated filter of...

Embodiment 3

[0033] This embodiment illustrates that the present invention can be used for purification of different circulating waters and has wide applicability.

[0034] The circulating water volume of the circulating cooling system of a petrochemical fertilizer plant in China is 12000m 3 / h, side filter processing capacity is 400m 3 / h, the original water quality data in normal production is: CODcr 80mg / L, BOD 5 15mg / L, ammonia nitrogen 15mg / L, turbidity 30mg / L. The biological aerated filter is installed near the sump in the form of a bypass, and the volume of the biological aerated filter is 800m 3 , with a velocity of 400m 3 / h, the hydraulic retention time is 2h. The water quality data of circulating water during normal production is CODcr 50mg / L, ammonia nitrogen 2mg / L, and turbidity 10mg / L. One day, a material leak occurred in the circulating water system, and the leaking heat exchanger was found within 12 hours and plugged. The leaked material was ammonia. The water quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com