Treatment method of polymer flooding oil production sewerage

A treatment method and technology for oily sewage, applied in mining wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., to achieve the effects of good adsorption performance, high COD removal rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

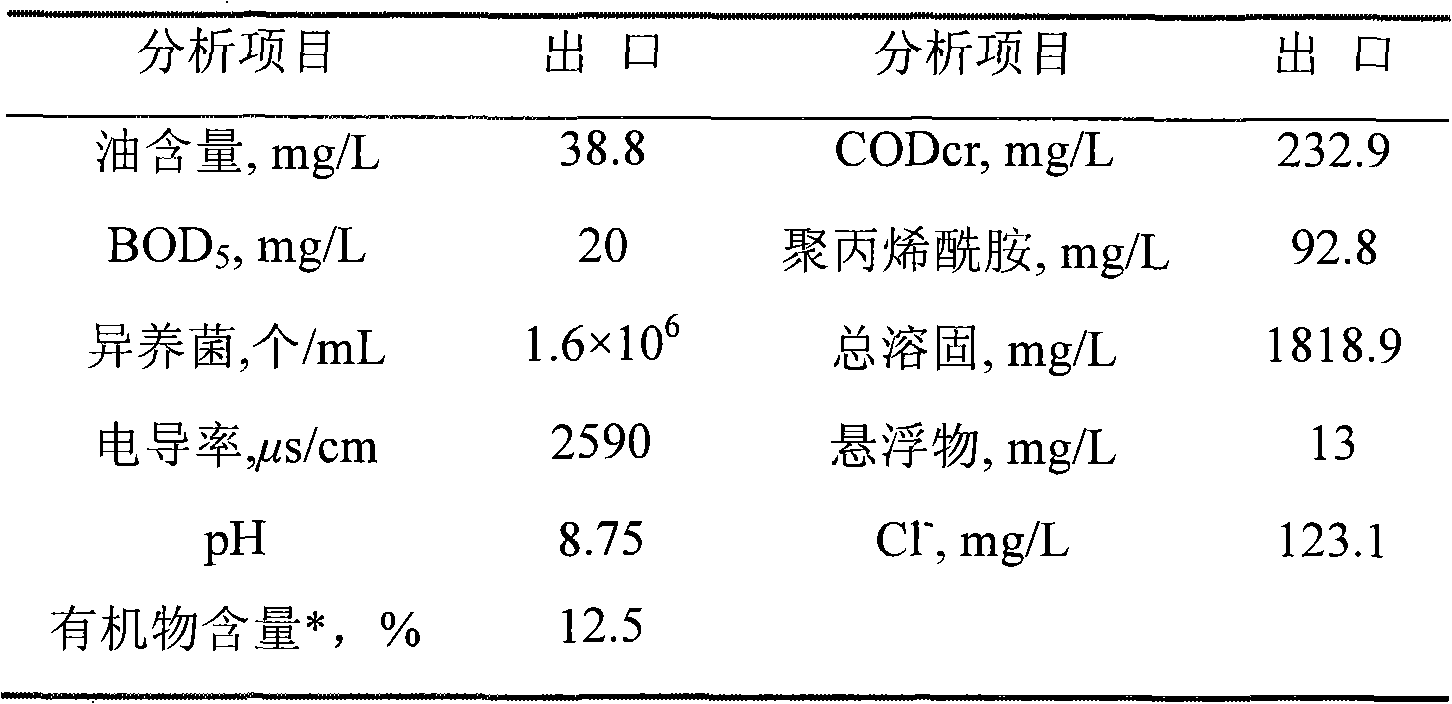

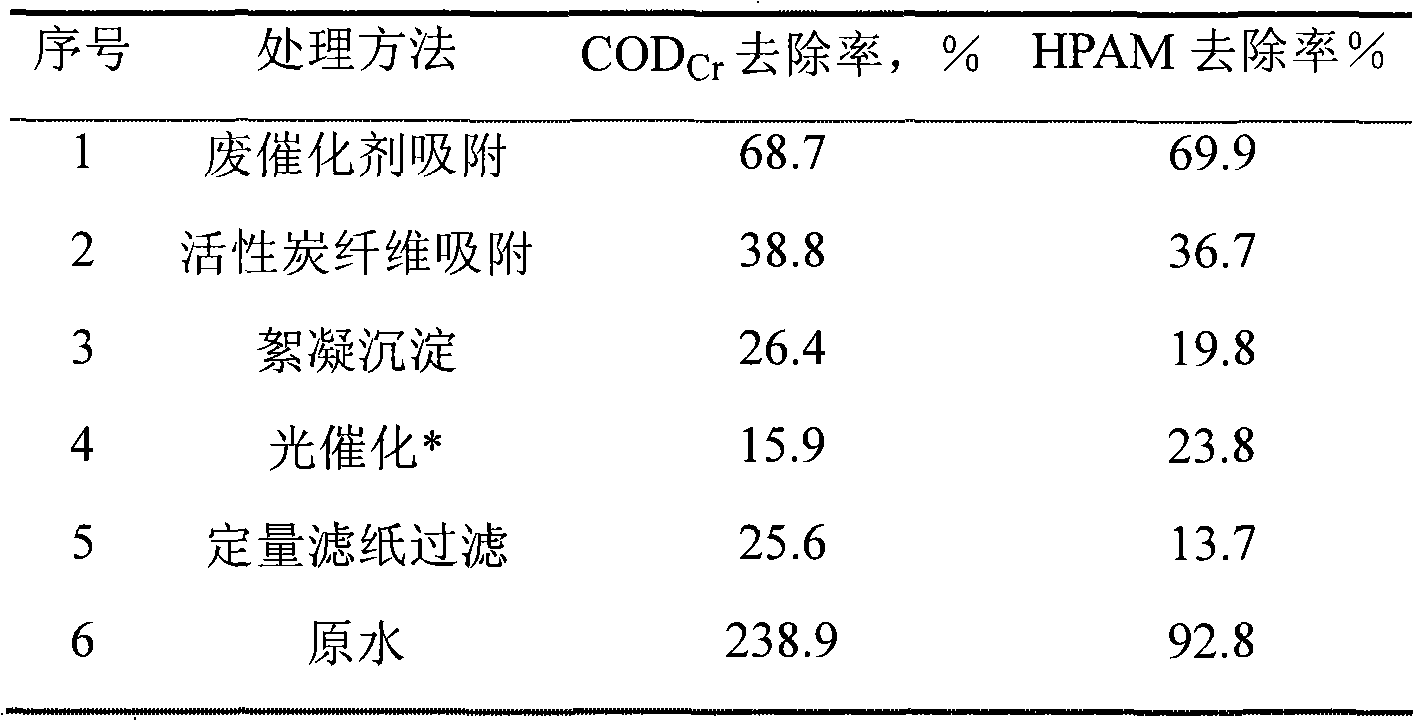

[0023] This example illustrates the results of different methods for treating the effluent of an oilfield joint station. See Table 1 for the water quality of the sewage. The spent catalytic cracking catalyst comes from the Cangzhou Oil Refinery with a specific surface area of 211m 2 / g, the pore volume is 0.203mL / g. Experimental method: Take 150mL of sewage from the joint station, add it to a 250mL beaker, add 5 grams of spent catalyst, 5 grams of activated carbon fiber, PAM+Al 2 (SO 4 ) 3 2mg / L+50mg / L, stirring for 2h, rotating speed 150r / min, conduct photocatalytic experiment on the water in the No. 4 beaker, filter the water in the No. 5 beaker, take samples to measure COD and HPAM after the experiment, the test results are shown in Table 2 .

[0024] Table 1

[0025]

[0026] *: The content of organic matter refers to the weight loss on ignition of the solid obtained from the total solution after burning at 550°C.

[0027] Table 2

[0028]

[0029] *The ligh...

Embodiment 2

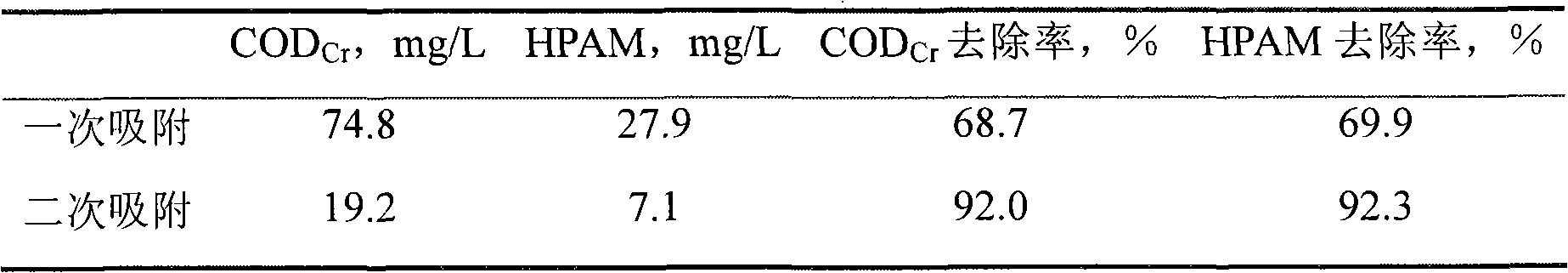

[0032]This example is a secondary adsorption experiment of spent catalysts on polymer flooding oil recovery wastewater. See Example 1 for the experimental water quality and spent catalyst composition.

[0033] Experimental method: Take 150mL of sewage from the joint station, add it to a 250mL beaker, add 5 grams of spent catalyst into the beaker, stir for 2 hours, rotate at a speed of 150r / min, and take a sample to measure COD Cr and HPAM, add 5 grams of waste catalyst to the effluent for secondary adsorption, and take samples to measure COD after adsorption Cr and HPAM, the results are shown in Table 3.

[0034] table 3

[0035]

[0036] The data in Table 3 show that the waste catalyst has a significant effect on the sewage treatment of the combined station, and the COD of the sewage after the second adsorption Cr The value can be reduced to 19.2mg / L, and HPAM can be reduced to 7.1mg / L, indicating that the spent catalyst has a good complexing and adsorption effect on oi...

Embodiment 3

[0038] This example shows the optimal adsorption capacity of the spent catalyst to the polyacrylamide solution. Prepare a polyacrylamide standard solution with a concentration of 200mg / L, add different quality spent catalysts, vibrate on a shaking table for 1.5h, and take a sample to measure the COD of sewage after standing for 0.5h Cr values, and the results are shown in Table 4.

[0039] The optimal static adsorption capacity of the spent catalyst on the polyacrylamide solution was investigated, and the results are shown in Table 4.

[0040] Table 4

[0041]

[0042] From the test results in Table 4, it can be seen that under the test conditions, the waste catalyst has the best adsorption performance for polyacrylamide-containing wastewater, and the adsorption performance decreases when the amount of adsorbent is reduced or increased, and the adsorption capacity for polyacrylamide solution is static The best adsorption capacity is: 40.6mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com