Alkali metal-containing silver-copper-nickel sliding electrical contact material

A sliding electrical contact, alkali metal technology, applied in the direction of metal/alloy conductors, circuits, connections, etc., can solve the problems that the service life of the alloy cannot fully meet the use requirements, the wear rate is fast, and the arc damage is large, and the cost is low. Material damage, reduced ablation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

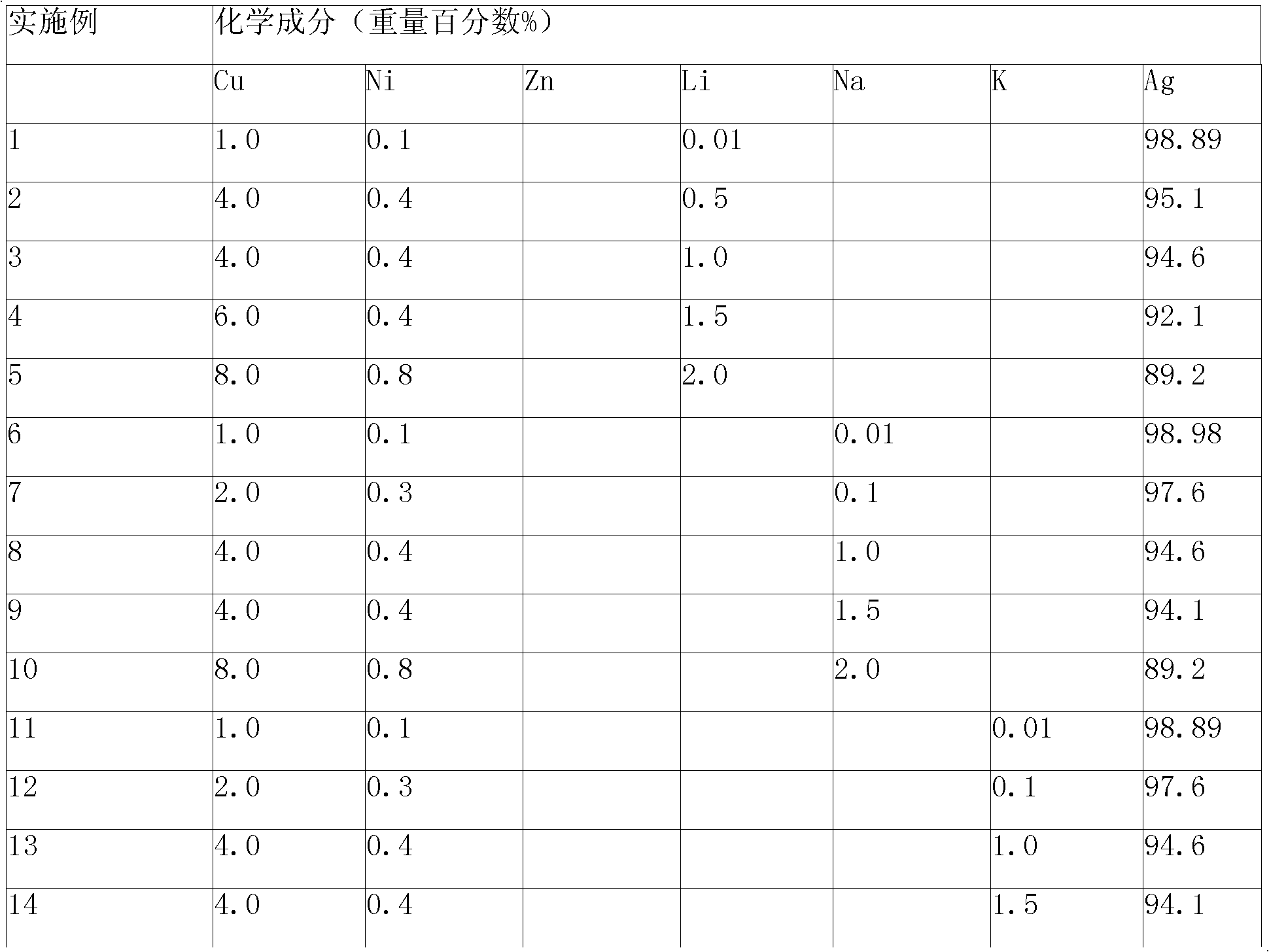

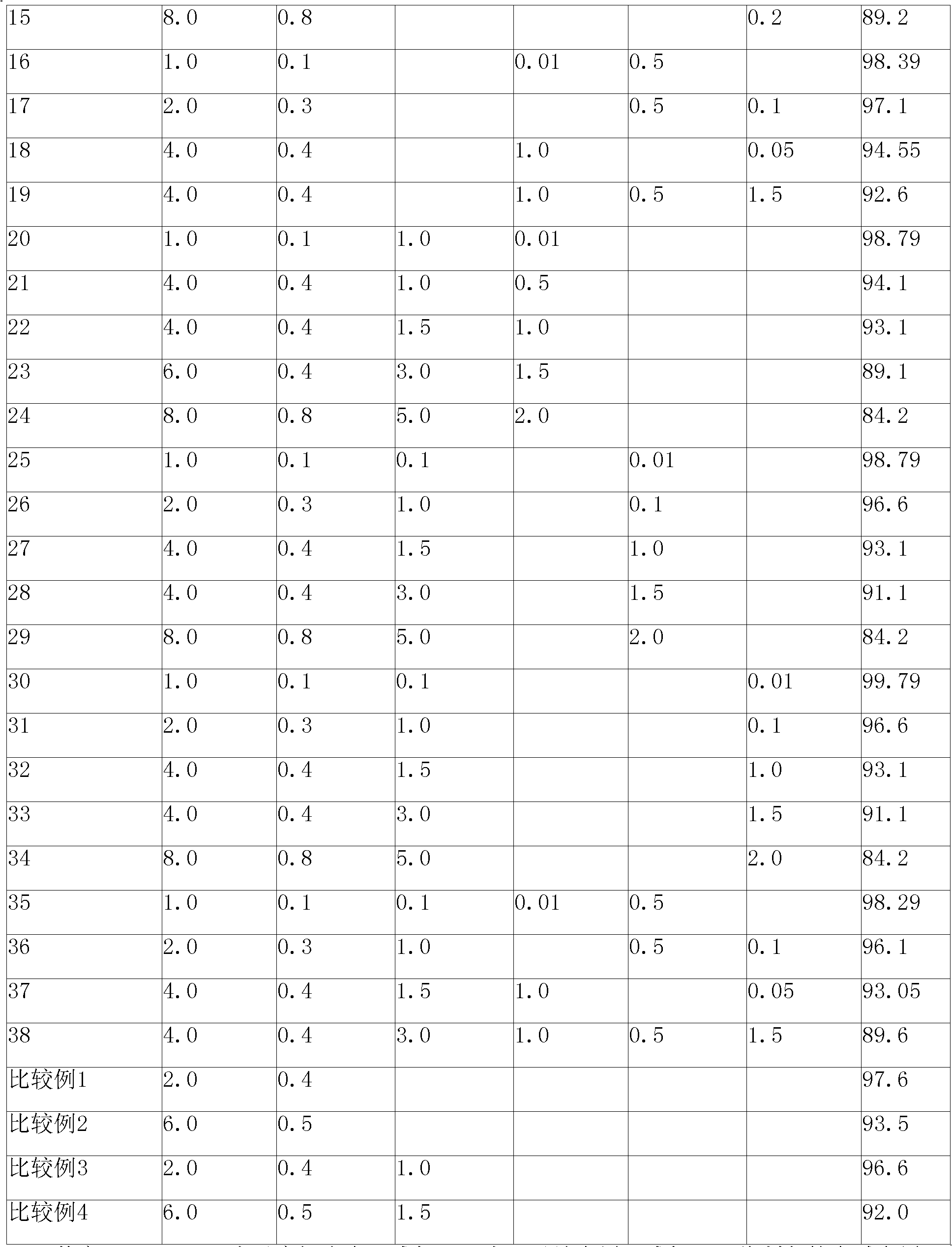

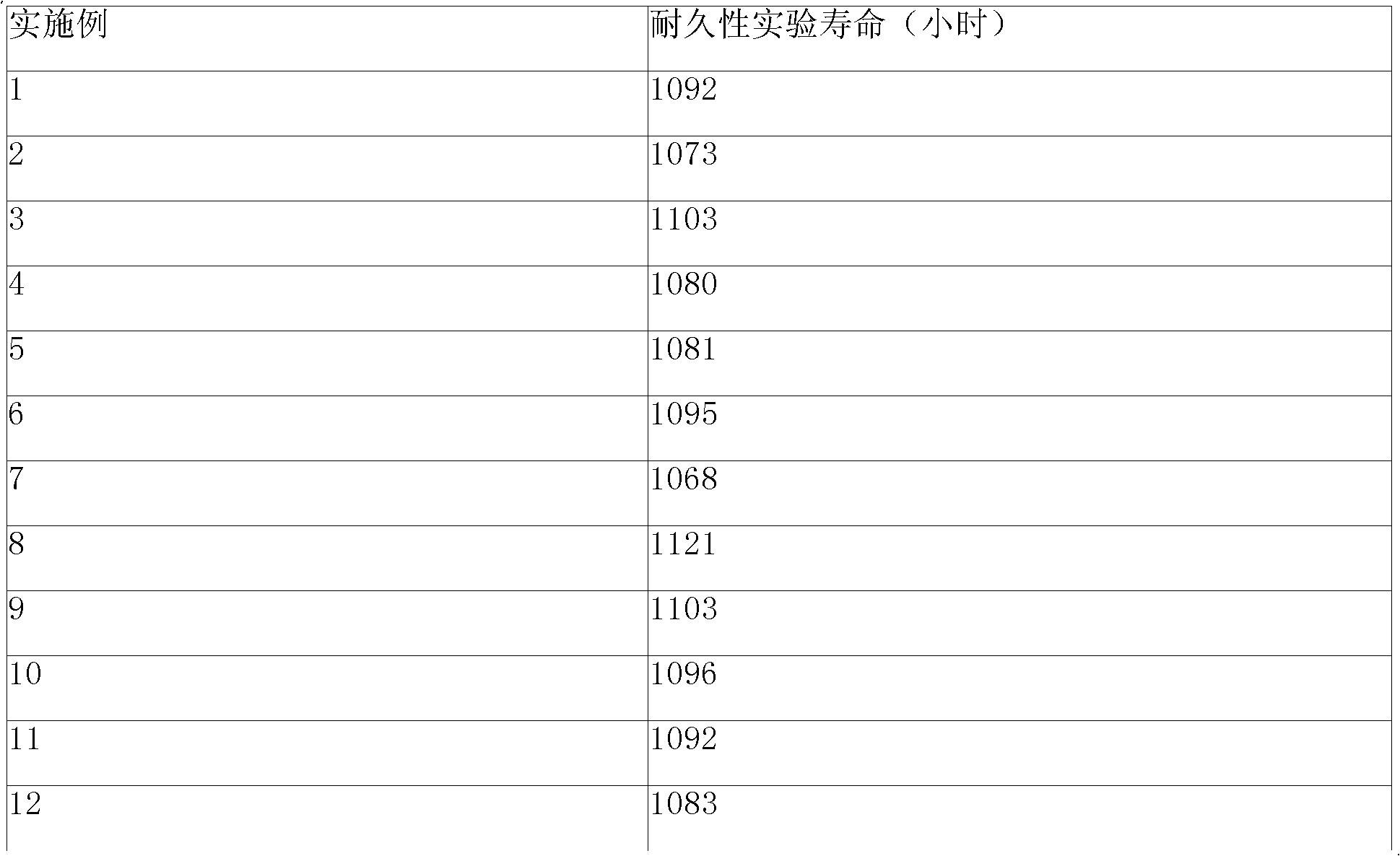

Method used

Image

Examples

Embodiment 39

[0046] The difference from Example 2 is that a layer of AuAg40 alloy with a thickness of about 1 μm is further compounded on the surface of the two-layer composite material, and then tested, and its service life is 1320 hours.

Embodiment 40

[0048] The difference from Example 8 is that a layer of AuAg40 alloy with a thickness of about 1 μm is further compounded on the surface of the two-layer composite material, and then tested, and its service life is 1372 hours.

Embodiment 41

[0050]The difference from Example 13 is that a layer of AuAg40 alloy with a thickness of about 1 μm is further compounded on the surface of the two-layer composite material, and then tested, and its service life is 1366 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com