Lead-acid cell grouping method

A lead-acid battery, battery technology, applied in the direction of lead-acid battery, secondary battery repair/maintenance, electricity measurement, etc., can solve the problems of single lagging, single test conditions, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Connect the fully charged 6-DZM-10 lead-acid battery to the pulse discharge device (18V300A charge and discharge detection device produced by BITRODE, an American company, BITRODE, model: LCN2-300-12), and connect the sampling line.

[0029] Discharge at 7C for 2s and let stand for 30min.

[0030] Discharge with 10C current for 1s and let stand for 30min.

[0031] Discharge with 20C current for 0.2s and let stand for 30min.

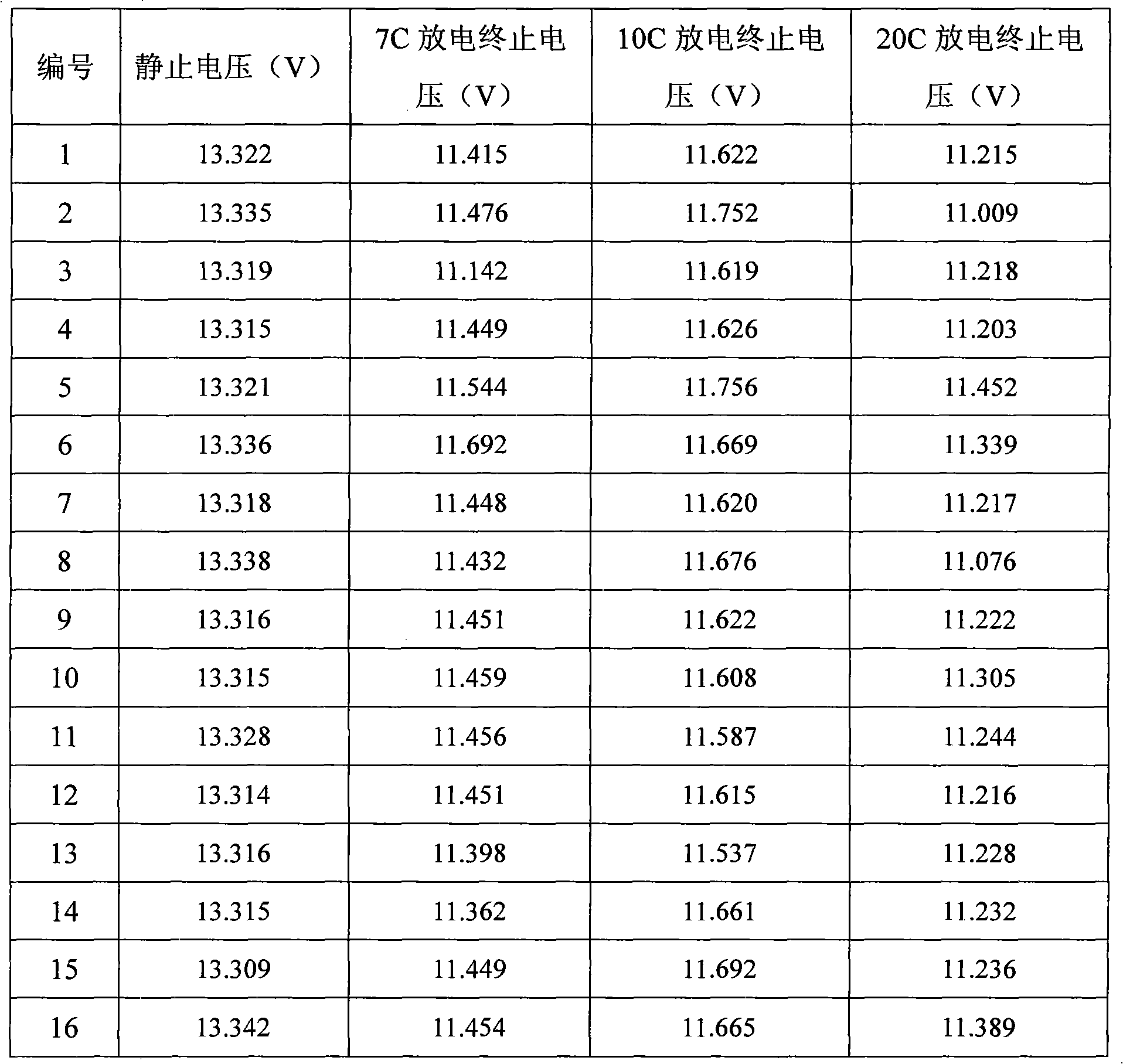

[0032] Record the static voltage and the end-of-discharge voltage, see Table 1 for specific data:

[0033] Static voltage and discharge data of each battery in Table 1 Example 1

[0034]

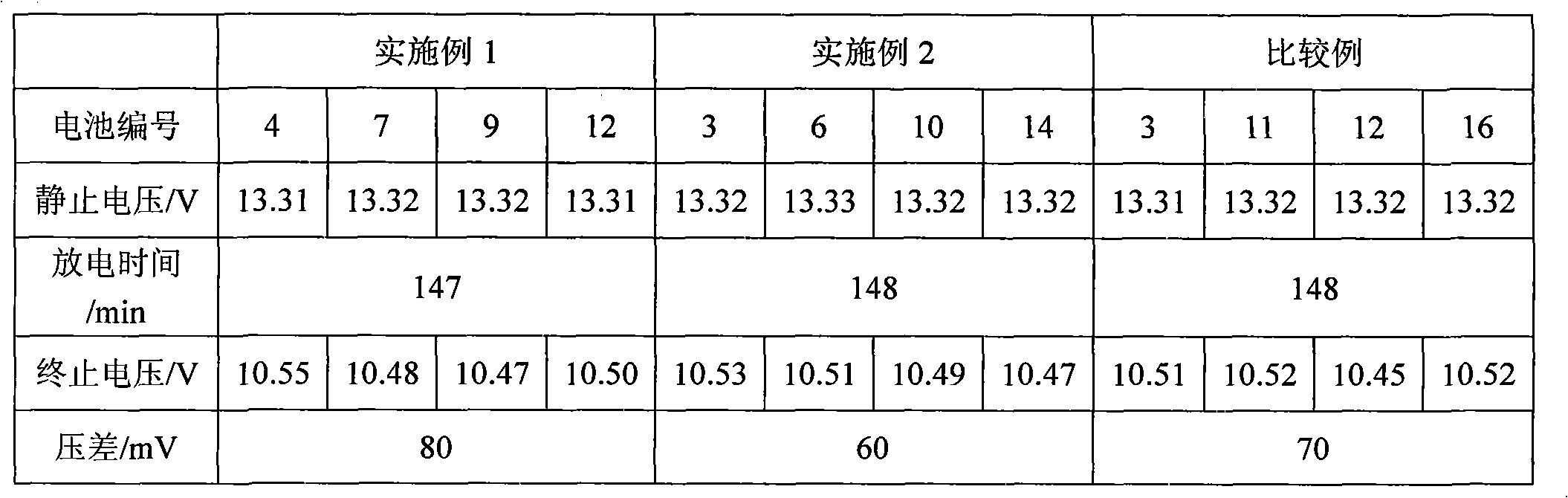

[0035] According to the static voltage difference of 10mV and the discharge end voltage difference of 20mV, the batteries 4, 7, 9, and 12 are combined into a group. The difference between the maximum static voltage and the minimum static voltage of each battery in the matched battery pack is 4mV, which is less than the upper limit of 10mV; the difference be...

Embodiment 2

[0037] Connect the fully charged 6-DZM-10 lead-acid battery to the internal resistance voltage tester (produced by Guangzhou Chenwei Electronic Technology Co., Ltd., model: MP-20-S (200 / 2000mΩ)) on the internal resistance voltage tester, Check battery internal resistance.

[0038] Connect the fully charged 6-DZM-10 lead-acid battery to the pulse discharge device (18V300A charge and discharge detection device produced by BITRODE, an American company, BITRODE, model: LCN2-300-12), and connect the sampling line.

[0039] Discharge with 8C current for 2s.

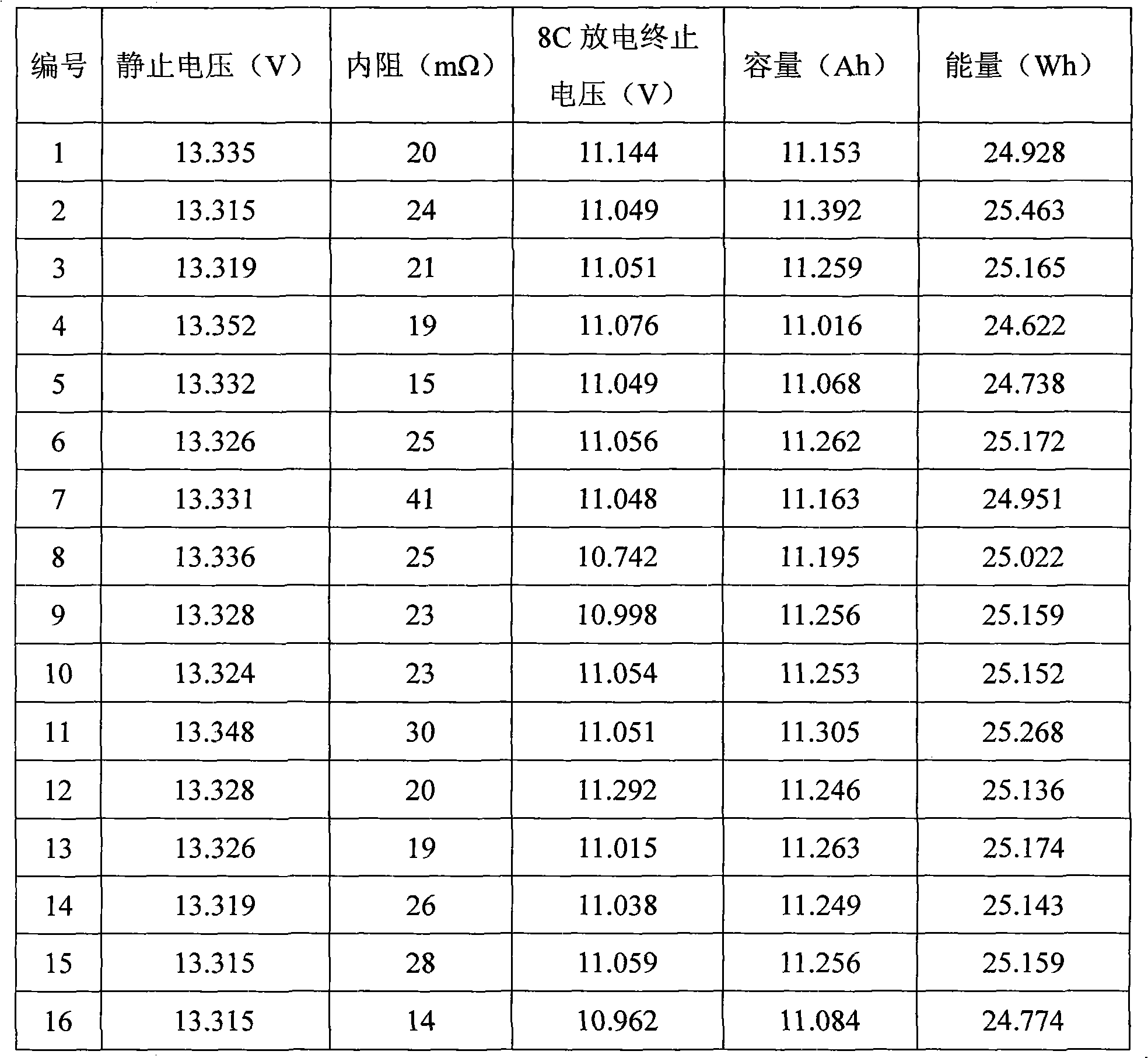

[0040] Record the discharge status and data, see Table 2 for specific data:

[0041] Static voltage, internal resistance and discharge data of each battery in table 2 embodiment 2

[0042]

[0043] According to internal resistance difference 5mΩ, static voltage difference 10mV, discharge end voltage difference 30mV, capacity difference 20mAh (ie 0.02Ah), energy difference 0.04Wh range, the batteries 3, 6, 10, 14 are matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com