Coal-rock interface identification method, identification system and identification probe

An identification system and identification method technology, applied in the field of identification systems and identification probes, can solve the problems of reliability, practicability, and safety that have not yet been fully verified, practical technologies and products have not yet been formed, and the use of identification technology is limited. Low mechanical wear, high recovery rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

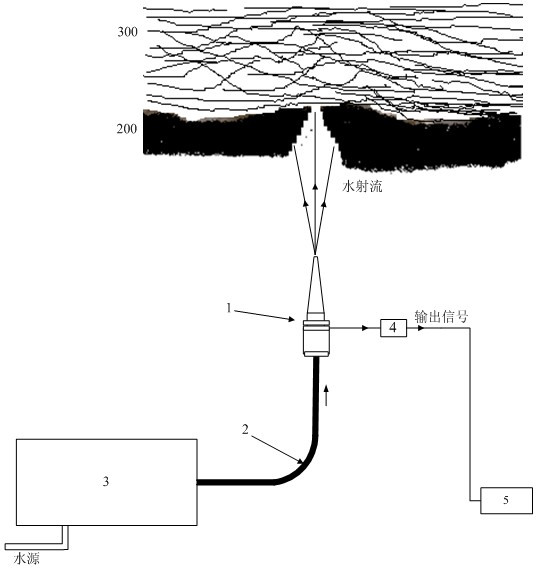

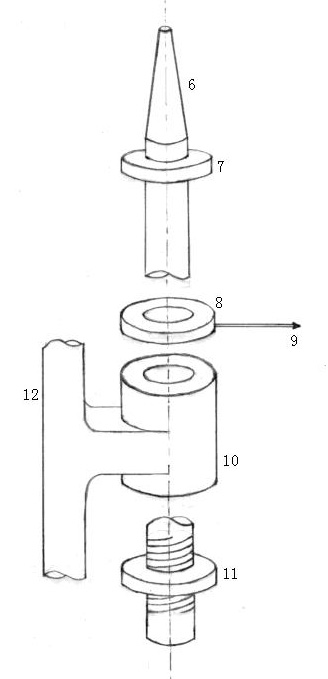

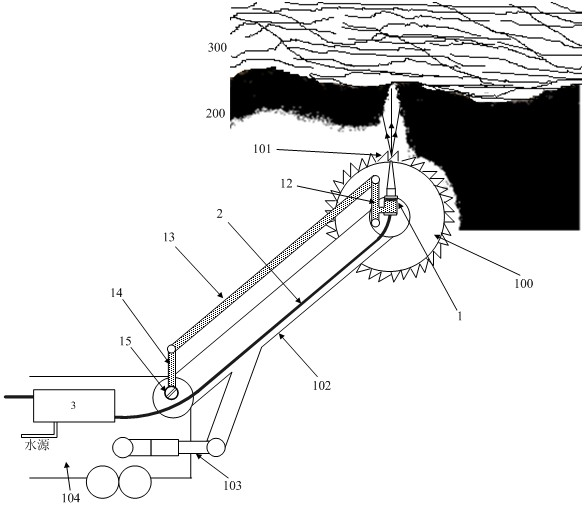

[0048] 1. Water jet driving pressure and nozzle selection.

[0049] The hydraulic parameters of water jet mainly include jet driving pressure, flow or nozzle diameter, and power. Among them, for any water jet system, choosing a reasonable driving pressure level is a key issue. According to the relevant literature of water jet, some commonly used pressure levels are shown in the table below.

[0050] Common water jet pressure ratings

[0051] Applications

Driving pressure / MPa

Water jet cleaning mine car

35~70

Water jet cutting coal seam

35~70

Water jet cutting sandstone or granite

70~100

Water jet cutting marble or basalt

100~150

Water jets drill holes in hard rock

250~300

[0052] It can be seen that it is not difficult to select a driving pressure that can cut through the coal seam but cannot cut the rock layer, and of course the parameters of the nozzle must be combined. Depending on the surrounding roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com