Device and method for depositing ultrathin alumina film by atomic layer

A technology of atomic layer deposition and aluminum oxide, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of complex surface chemical reactions, no substantial breakthroughs, and few reports. To achieve the effect of solving high temperature heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

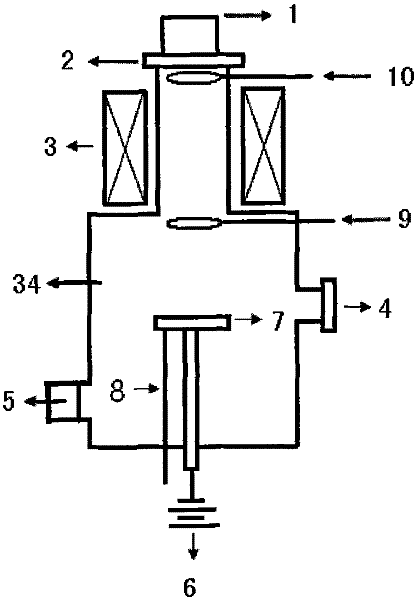

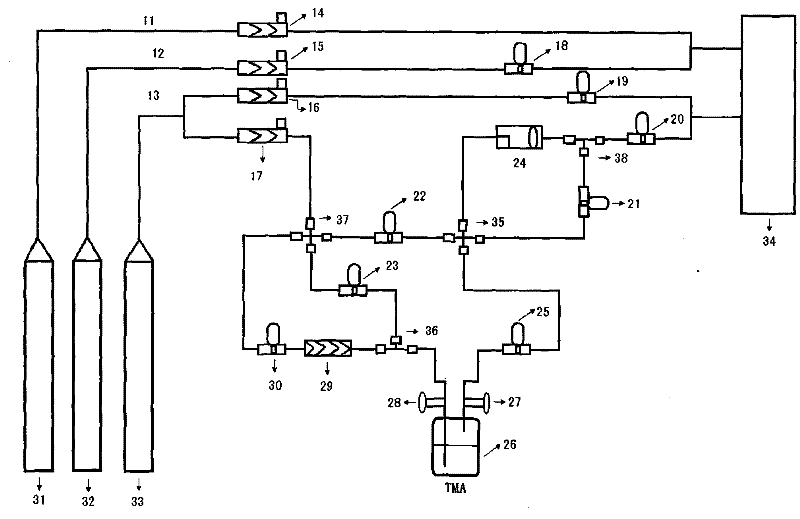

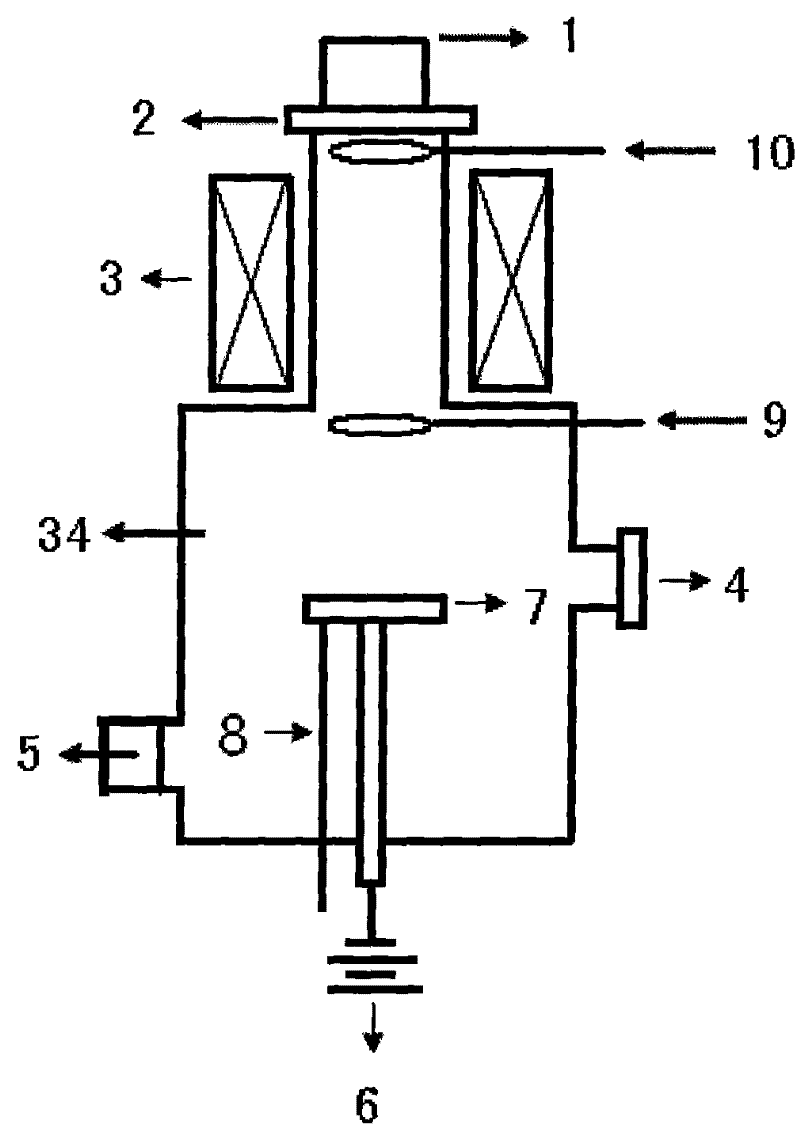

[0023] 1. First, pump the vacuum chamber 34 to the background pressure, which is about 0.001 Pa; then turn the first mass flow controller 14 to clean and vacuum the discharge argon pipeline 11 to 0.001 Pa, and then close the first mass flow controller 14. A mass controller 14; open the first pneumatic valve 18, beat the second mass flow controller 15 to clean, carry out the vacuum pumping of the pipeline 12 to 0.001 Pa, then close the second mass flow controller 15 and the first Pneumatic valve 18; open the second pneumatic valve 19, turn on the third mass flow controller 16 for cleaning, perform pumping of the pipeline 13, close the third mass flow controller 16 and the second pneumatic valve 19 after pumping to 0.001 Pa Open the 3rd pneumatic valve (20), the 4th pneumatic valve 21, the 5th pneumatic valve 22, the 6th pneumatic valve 23, the 7th pneumatic valve 25, the 8th pneumatic valve 30 successively, and the 4th mass flow controller 17 After cleaning, pump the pipeline t...

example 1

[0033] 1. First, pump the vacuum chamber 34 to the background pressure, which is about 0.001 Pa; then turn the first mass flow controller 14 to clean and vacuum the discharge argon pipeline 11 to 0.001 Pa, and then close the first mass flow controller 14. A mass controller 14; open the first pneumatic valve 18, beat the second mass flow controller 15 to clean, carry out the vacuum pumping of the pipeline 12 to 0.001 Pa, then close the second mass flow controller 15 and the first Pneumatic valve 18; open the second pneumatic valve 19, turn on the third mass flow controller 16 for cleaning, perform pumping of the pipeline 13, close the third mass flow controller 16 and the second pneumatic valve 19 after pumping to 0.001 Pa Open the 3rd pneumatic valve 20, the 4th pneumatic valve 21, the 5th pneumatic valve 22, the 6th pneumatic valve 23, the 7th pneumatic valve 25, the 8th pneumatic valve 30 successively, and the 4th mass flow controller 17 is beaten to Clean, pump the pipeline...

example 2

[0044]1. First, pump the vacuum chamber 34 to the background pressure, which is about 0.001 Pa; then turn the first mass flow controller 14 to clean and vacuum the discharge argon pipeline 11 to 0.001 Pa, and then close the first mass flow controller. A mass controller 14; open the first pneumatic valve 18, beat the second mass flow controller 15 to clean, carry out the vacuum pumping of the pipeline 12 to 0.001 Pa, then close the second mass flow controller 15 and the first Pneumatic valve 18; open the second pneumatic valve 19, turn on the third mass flow controller 16 for cleaning, perform pumping of the pipeline 13, close the third mass flow controller 16 and the second pneumatic valve 19 after pumping to 0.001 Pa Open the 3rd pneumatic valve 20, the 4th pneumatic valve 21, the 5th pneumatic valve 22, the 6th pneumatic valve 23, the 7th pneumatic valve 25, the 8th pneumatic valve 30 successively, and the 4th mass flow controller 17 is beaten to Clean, pump the pipeline to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com