Ampoule scoring machine

A scoring machine and ampoule technology, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of small ampoule breaking force, achieve small ampoule breaking force, reduce particle and microbial contamination, and facilitate clinical work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

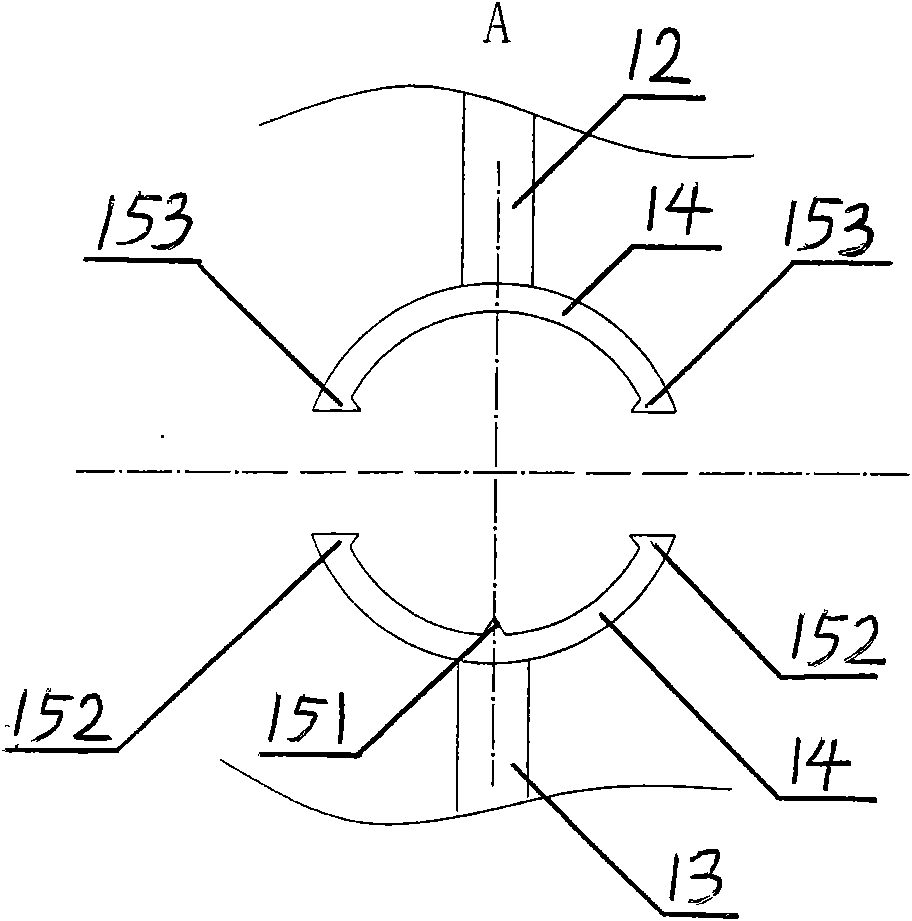

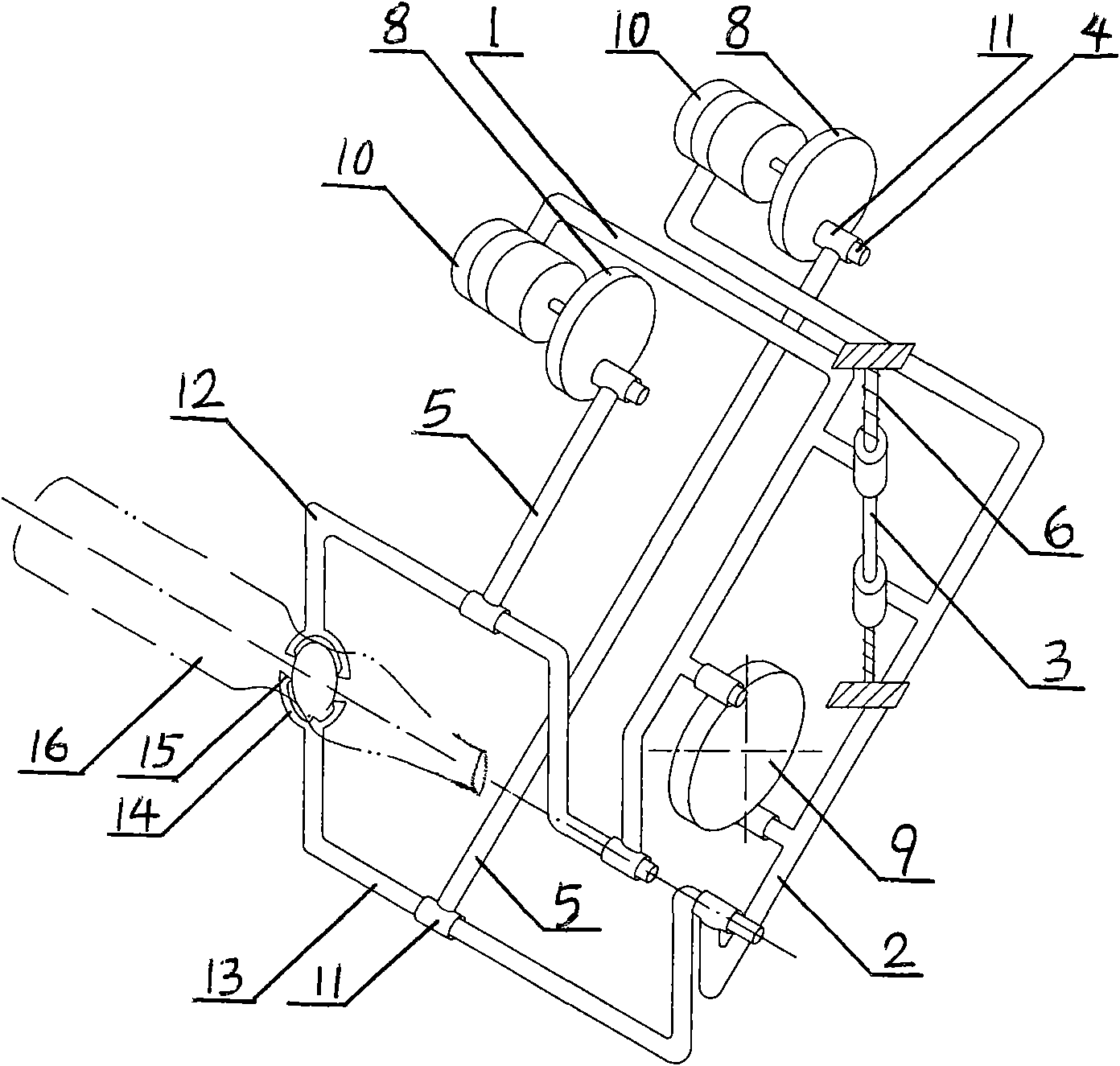

[0013] Explanation of the main structure and details in the accompanying drawings:

[0014] 1——upper moving frame 2——lower moving frame 3——sliding frame 4——shaft

[0015] 5——Connecting Rod 6——Spring 7——Linkage Crank 8——Crank

[0016] 9——linkage cam 10——electric motor 11——shaft sleeve 12——upward moving tool rest

[0017] 13——Down moving knife holder 14——Slider 15——Knife tip 16——Ampoule

[0018] 151——Main scoring tip 152——Secondary scoring tip 153——Side scoring tip

[0019] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the ampoule scoring machine of the present invention consists of an upper moving frame 1, a lower moving frame 2, a sliding frame 3, a shaft 4, a connecting rod 5, a spring 6, a linked crank 7, a crank 8, a linked cam 9, a motor 10, and an axle sleeve 11. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com