Slit adjusting device capable of adjusting slit width in double directions

An adjustment device and two-way adjustment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor processing technology, complex mechanical structure, difficult assembly, etc., and achieve simple and beautiful appearance, simple device structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

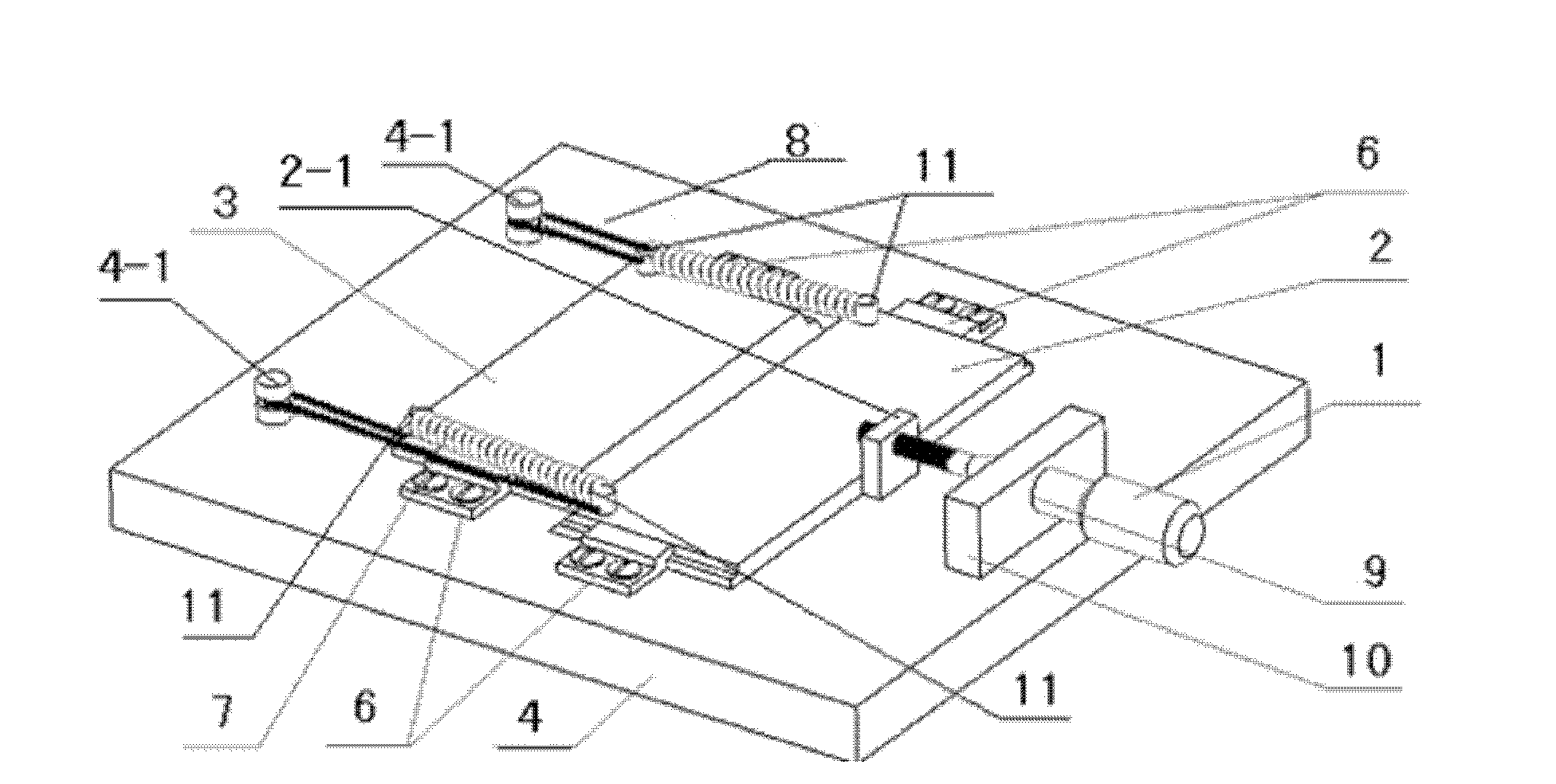

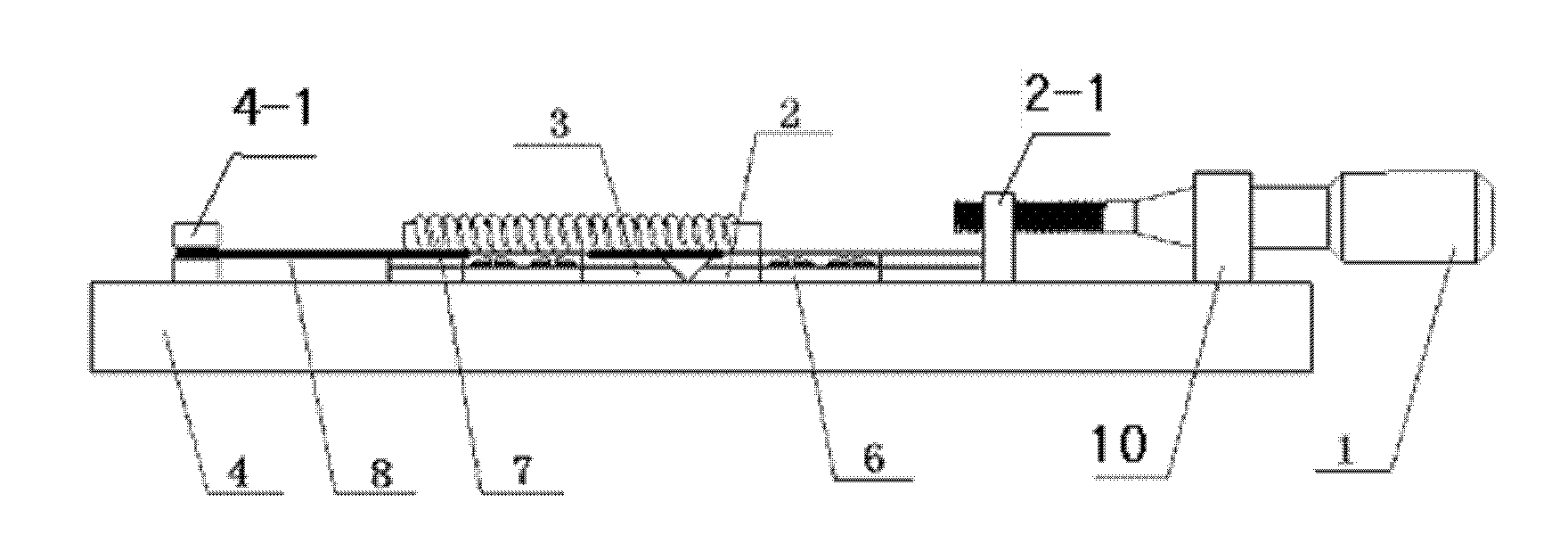

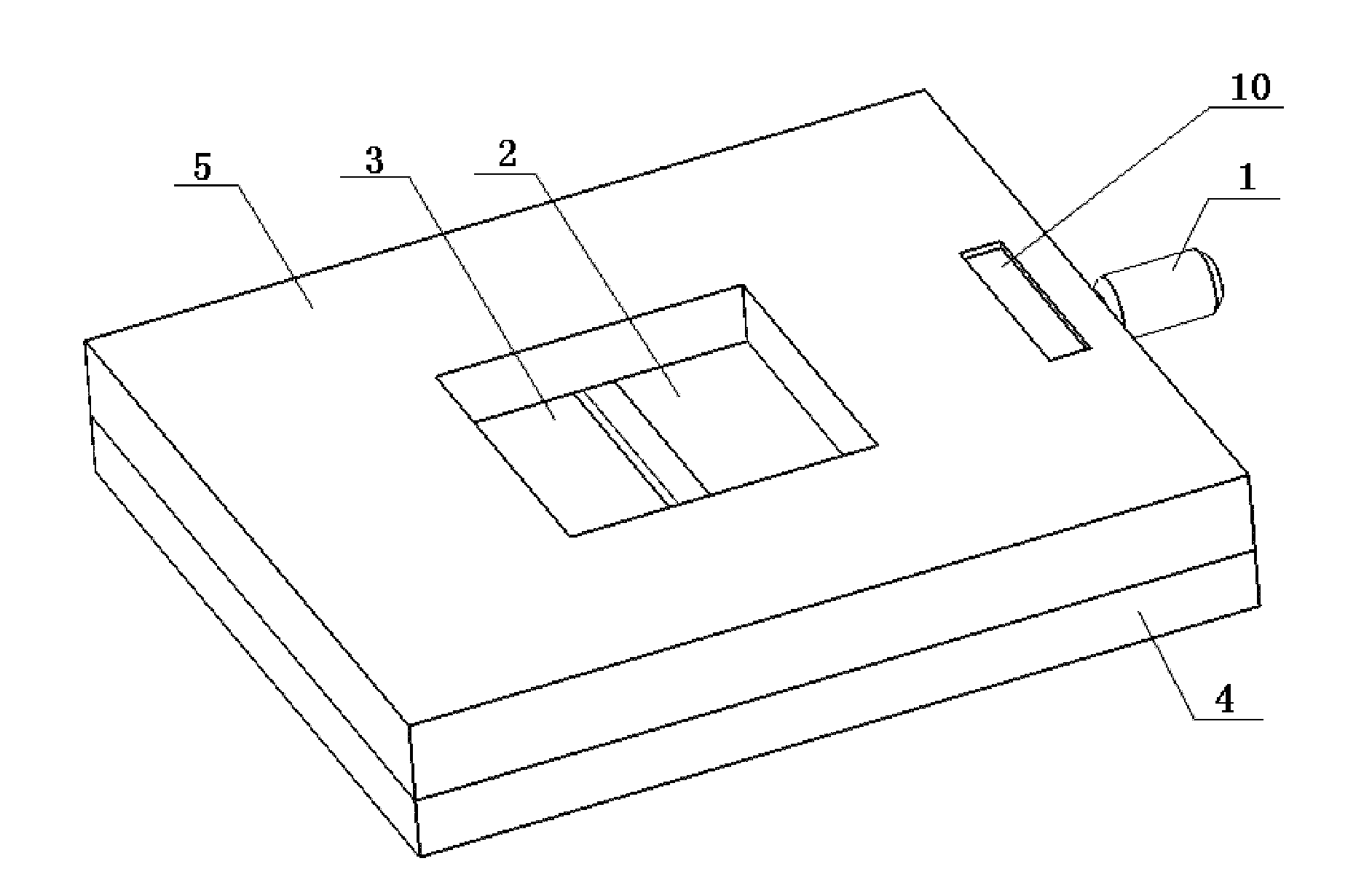

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, a slit adjustment device that can adjust the slit width bidirectionally, including an adjusting screw 1, a first slit blade 2, a second slit blade 3, a main body base 4 and a support plate 10; it also includes two To the guide vane 6, tension spring 7 and thrust bearing 9; one end of the guide vane 6 is set to a stepped shape, and the other end is fixed on the main body base 4, the first slit blade 2 and the second slit blade 3 Both ends are respectively processed into a stepped shape, the first slit blade 2 and the second slit blade 3 are arranged between two pairs of guide vanes 6, the two ends of the first slit blade 2 and the second slit blade 3 The stepped shape matches the stepped shape provided at one end of the two pairs of guide vanes 6; the two ends of the first slit blade 2 and the second slit blade 3 are respectively symmetrically arranged with two fixing screws 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com