Method for progressive gas drainage in high gas medium-hard coal seam

A gas drainage, progressive technology, applied in gas discharge, earthwork drilling, safety devices, etc., to achieve the effect of improving safety and reliability, reducing air distribution, and eliminating hidden dangers of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1, high-power drilling rig progressive module gas drainage,

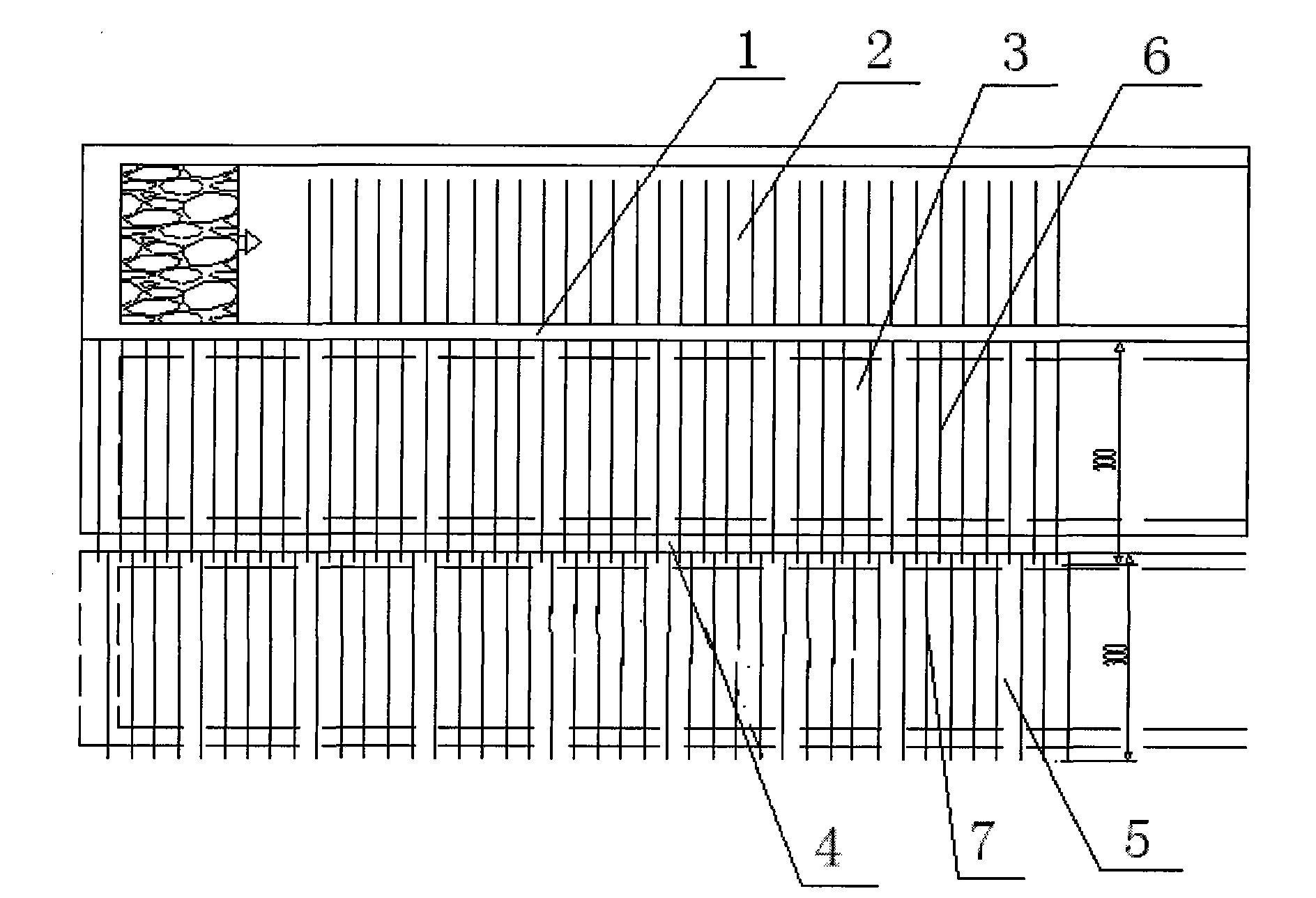

[0016] like figure 1 As shown, when excavating the mining face 2 with multi-lane arrangement, the long boreholes are constructed in advance in the next adjacent mining face area 3 in the outer side groove 1 of the mining face 2, and the long holes are constructed every 5-10m Use domestic high-power drilling rigs to arrange construction long boreholes 6 to the adjacent mining face. The boreholes are basically arranged vertically to the roadway. The length is not less than 300m, and the drainage range covers the adjacent mining face and its trough. During the excavation of the current mining face 2, the excavation area of the next mining face area 3 will be drained in advance to ensure that the next mining face 3 There is a drainage time of 1-3 years, and the roadway excavation of the next mining face area 3 is carried out in the position of the roadway strip 4 that has been drained for 1-3 years. Th...

Embodiment 2

[0017] Example 2, using a kilometer drilling rig for progressive gas drainage. like figure 2 indicated,

[0018] A progressive gas drainage method for high-gas medium-hard coal seams. When excavating a mining working face 2 arranged with multiple lanes, construction is carried out on the outer side of the mining working face 2 along the groove 1 to the next adjacent working face in advance. Long borehole 6, the length of the borehole is required to be able to penetrate at least the distance between the reserved roadway strips on both sides of the next two mining face areas, 500-600m, including two working faces. Drain the excavation area of the next mining face area 3 to ensure that the next mining face area 3 has a drainage time of 1-3 years. The three-year roadway strip 4 has been carried out, and the gas has dropped to a controllable level, and the gas content in the mining face area 3 has also dropped to a safe level; Construct long-distance drilling in area 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com