Method for preparing levulinic acid by catalyzing bamboo shoot shells through functional ionic liquid

A technology of levulinic acid and ionic liquid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate and other directions, can solve the problems of unrecoverable acid liquid, no reuse, high reaction temperature, etc. Hydrolysis reaction rate and reaction efficiency, promoting reaction rate and quality, and the effect of strong transformation specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

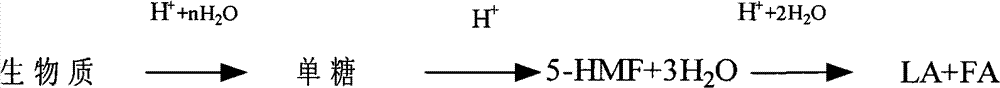

Method used

Image

Examples

Embodiment 1

[0039] Bamboo shoot shells (bamboo shoots, Phyllostachys Praecox f.preveynalis, origin Taihuyuan Town, Lin’an, Zhejiang Province) were dried in an oven at 75°C to a moisture content of 9.1%, crushed to a particle size of less than 830 μm, and the functional ionic liquid was [C 2 mim]HSO 4 , The solid-liquid ratio of bamboo shoot shells and functional ionic liquid is 3:100; ultrasonic dissolution, ultrasonic working conditions are: ultrasonic power 1500W, working gap ratio 3s:5s, time 30min. Microwave reaction promotes catalytic conversion. Microwave working conditions are: microwave power 1200W, temperature setting 120°C, reflux cycle 2mL / min, helium protection and saturation for 20min, flow rate 3mL / min, stirring speed 120r / min, and reaction time 120min.

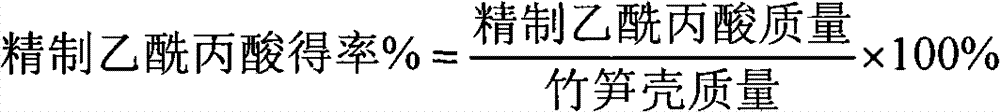

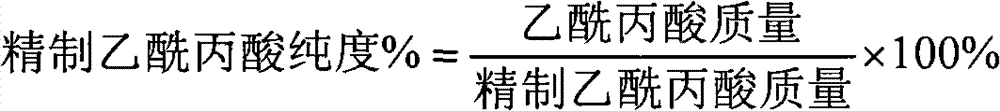

[0040] After the reaction, wash with 2 times the volume of water and centrifuge to obtain the levulinic acid aqueous solution and the functional ionic liquid respectively; then use an ultrafiltration system to remove the ma...

Embodiment 2

[0043] Bamboo shoot shells (bamboo shoots, Phyllostachys Praecox f.preveynalis, origin Taihuyuan Town, Lin’an, Zhejiang Province) were dried in an oven at 75°C to a moisture content of 10%, and crushed to a particle size of less than 830 μm. The functional ionic liquid was [C 4 mim]HSO 4 , the solid-liquid ratio of bamboo shoot shells and functional ionic liquid is 3:100; ultrasonic dissolution, ultrasonic working conditions are: ultrasonic power 1500W, working gap ratio 3s:5s, time 40min. Microwave reaction promotes catalytic conversion. Microwave working conditions are: microwave power 1200W, temperature setting 120°C, reflux cycle 2mL / min, helium protection, flow rate 3mL / min, stirring speed 120r / min, reaction time 130min.

[0044] After the reaction, wash with 2 times the volume of water and centrifuge to obtain the levulinic acid aqueous solution and the functional ionic liquid respectively; then use an ultrafiltration system to remove the macromolecular organic matter wi...

Embodiment 3

[0047] Bamboo shoot shells (bamboo shoots, Phyllostachys Praecox f.preveynalis, origin Taihuyuan Town, Lin’an, Zhejiang Province) were dried in an oven at 75°C to a moisture content of 11%, crushed to a particle size of less than 380 μm, and the functional ionic liquid was [C 6 mim]HSO 4 , the solid-liquid ratio of bamboo shoot shells and functional ionic liquid is 5:100, adding 0.7% tin dichloride by reactant weight; ultrasonic dissolution, ultrasonic working conditions are: ultrasonic power 1500W, working gap ratio 2s:5s, time 30min. Microwave reaction promotes catalytic conversion. Microwave working conditions are: microwave power 1200W, temperature setting 120°C, reflux cycle 2mL / min, helium protection and saturation for 20min, flow rate 3mL / min, stirring speed 120r / min, and reaction time 100min. The reactants were determined by gas chromatography.

[0048] After the reaction, wash with 2 times the volume of water and centrifuge to obtain the levulinic acid aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com