Substrate storing box

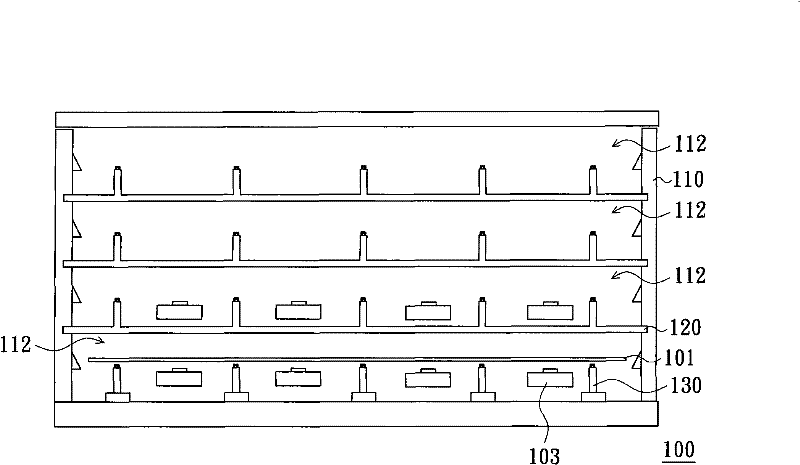

A storage and substrate technology, which is applied to containers to prevent mechanical damage, packaging of fragile items, containers, etc., can solve the problems of limited spacing range, difficulty in improving the space utilization rate of substrate storage box 100, etc. The effect of improving the yield of the manufacturing process and improving the transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

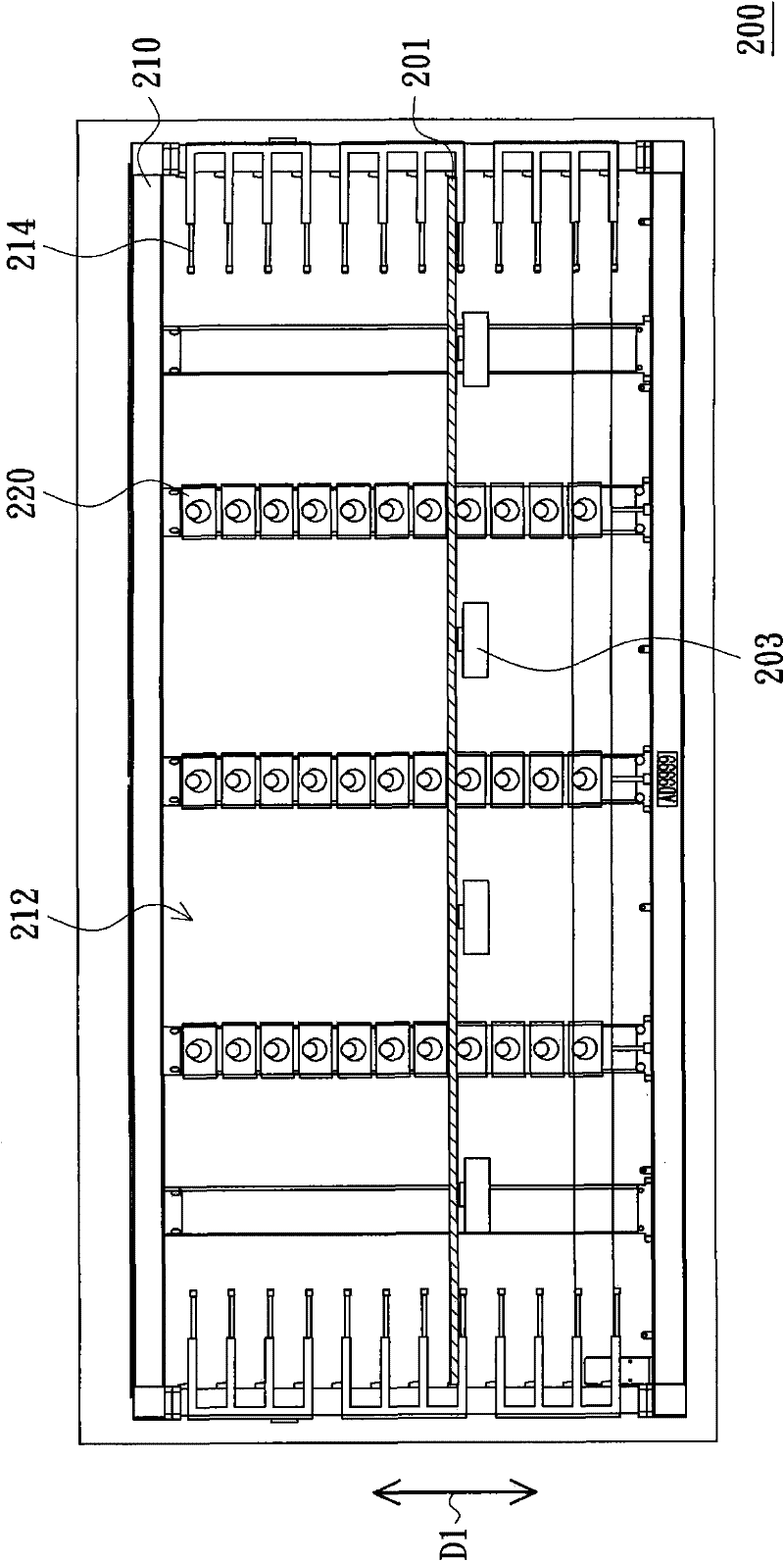

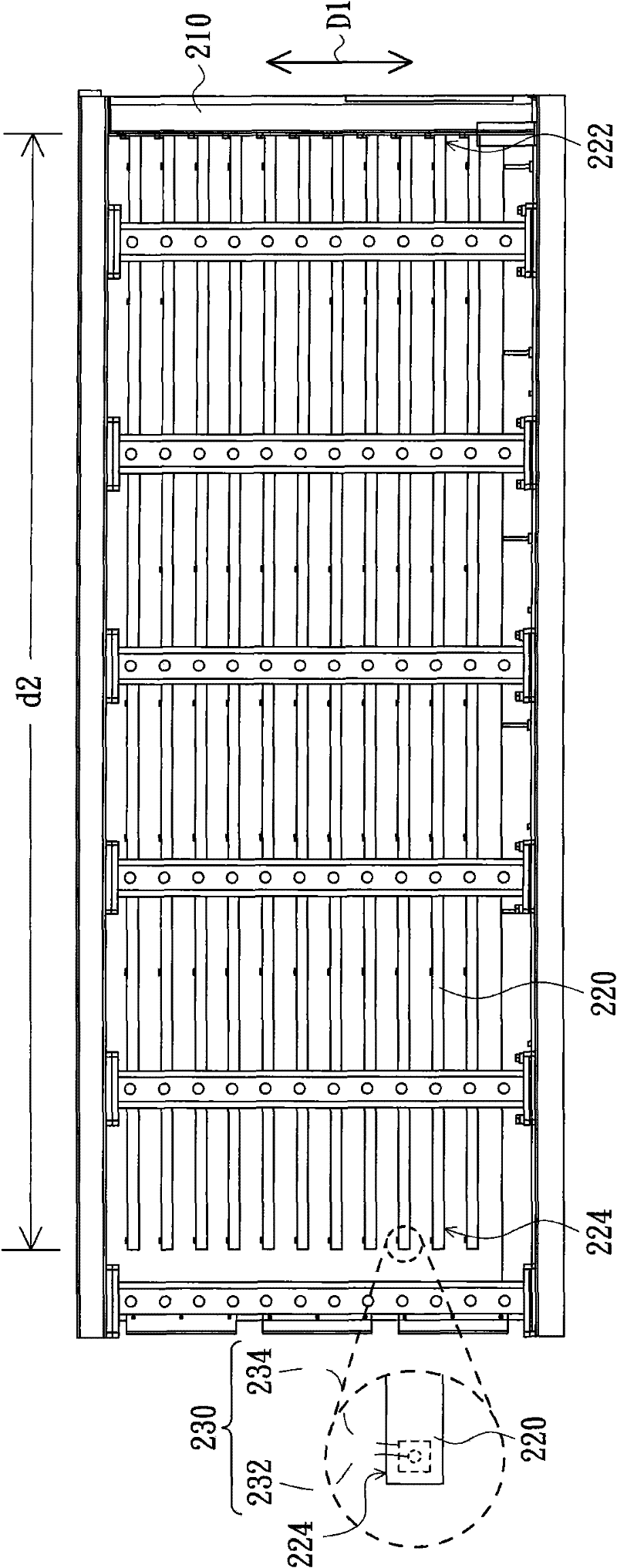

[0050] Figure 2A is a schematic front view of a substrate storage box for placing substrates in an embodiment of the present invention, Figure 2B for Figure 2A The schematic diagram of the side view of the substrate storage box for placing the substrate, image 3 Then it is a schematic cross-sectional view of the free end of the hollow cantilever support rod of the substrate storage box of FIG. 2 . Please refer to Figure 2A , Figure 2B and image 3 , the substrate storage box 200 includes a frame body 210 , a plurality of hollow cantilever rods 220 and a vibration damping device 230 . The hollow cantilever support rods 220 are disposed in the storage space 212 of the frame body 210 (the mark 212 cannot be found on the drawing), and each hollow cantilever support rod 220 has a fixed end 222 and a free end 224 respectively, wherein the fixed end 222 is fixed on the frame 210. That is to say, the free end 224 of the hollow cantilever rod 220 can vibrate back and forth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com