Continuous extrusion deformation method of magnesium alloy

A technology of extrusion deformation and magnesium alloy, which is applied in the field of continuous extrusion deformation of magnesium alloy, can solve the problems of affecting product quality, product quality decline, and many processes, so as to improve industrial production efficiency, high compressive strength, and high yield strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

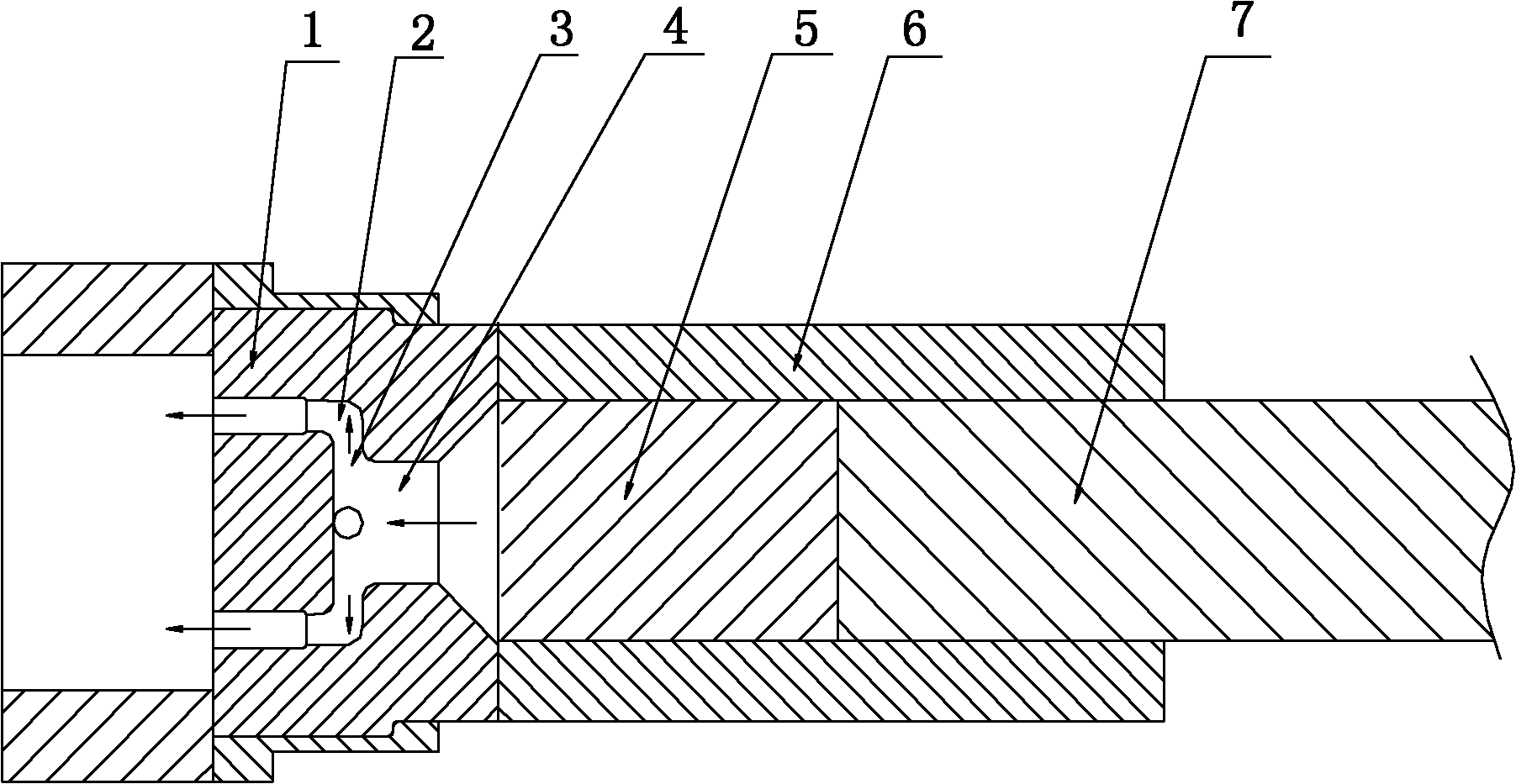

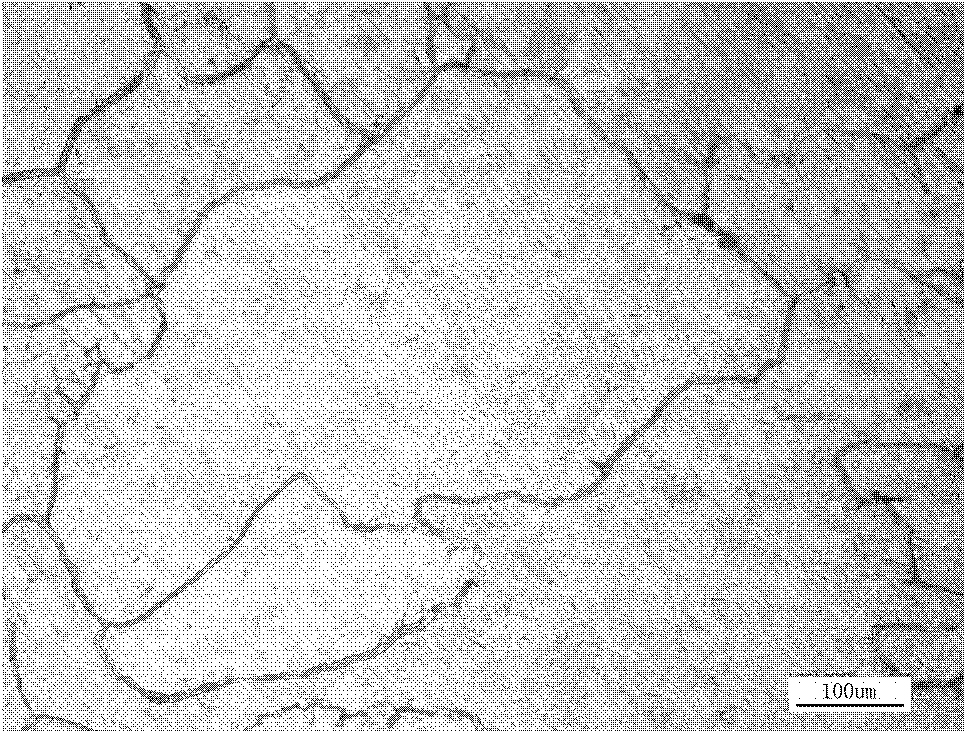

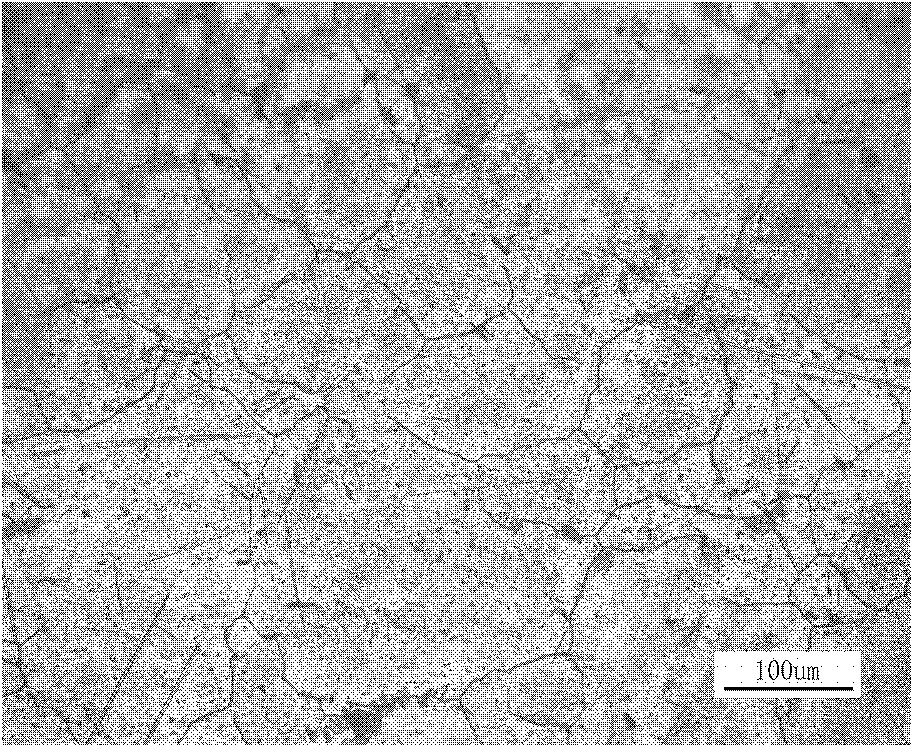

[0031] Example 1, taking the extrusion deformation of cast AZ31 magnesium alloy as an example, in order to make the comprehensive mechanical properties of the extruded rod of AZ31 magnesium alloy meet the high standard requirements, the magnesium alloy billet was heated to 400 ° C for 15 hours before extrusion After homogenization treatment, the AZ31 magnesium alloy billet with an average grain size of about 500 μm after homogenization treatment is heated to 350°C, put into an extrusion die heated to 330°C, and extruded on a horizontal extrusion machine. Pressing, with an extrusion force of 10Mpa ~ 20Mpa, with an extrusion speed of 3m / min, one by one in the order of forward extrusion, 90-degree variable channel angle extrusion, and 90-degree channel angle extrusion. Constant speed and one-way continuous extrusion, after the forward extrusion stage, the flow is divided into 4 streams in equal amounts, the extrusion ratio of the variable channel angle extrusion is 16:1 when the f...

Embodiment 2

[0035] Example 2, taking the extrusion deformation of cast AZ31 magnesium alloy as an example, in order to make the comprehensive mechanical properties of the extruded rod of AZ31 magnesium alloy meet the high standard requirements, the magnesium alloy billet was heated to 400 ° C for 15 hours before extrusion After homogenization treatment, the AZ31 magnesium alloy billet with an average grain size of about 500 μm after homogenization treatment is heated to 400°C, put into an extrusion die heated to 380°C, and extruded on a horizontal extrusion machine. Pressing, with an extrusion force of 15-18Mpa, and an extrusion speed of 2m / min, one by one in the order of forward extrusion, 90-degree variable channel angle extrusion, and 90-degree channel angle extrusion. Constant speed and one-way continuous extrusion, after the forward extrusion stage, the flow is divided into 4 streams in equal amounts, the extrusion ratio of the variable channel angle extrusion is 16:1 when the forward...

Embodiment 3

[0036] Example 3, taking the extrusion deformation of cast AZ31 magnesium alloy as an example, in order to make the comprehensive mechanical properties of the extruded rod of AZ31 magnesium alloy meet the high standard requirements, the magnesium alloy billet was heated to 400 ° C for 15 hours before extrusion After homogenization treatment, the AZ31 magnesium alloy billet with an average grain size of about 500 μm after homogenization treatment is heated to 450°C, put into an extrusion die heated to 420°C, and extruded on a horizontal extrusion machine. Pressing, with an extrusion force of 10Mpa ~ 20Mpa, with an extrusion speed of 3m / min, one by one in the order of forward extrusion, 90-degree variable channel angle extrusion, and 90-degree channel angle extrusion. Constant speed and one-way continuous extrusion, after the forward extrusion stage, the flow is divided into 4 streams in equal amounts, the extrusion ratio of the variable channel angle extrusion is 16:1 when the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com