Improved process for producing yellow wine

A production process, rice wine technology, applied in the field of brewing technology, can solve problems such as mash rancidity, achieve long aftertaste, solve mash rancidity, and improve wine yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

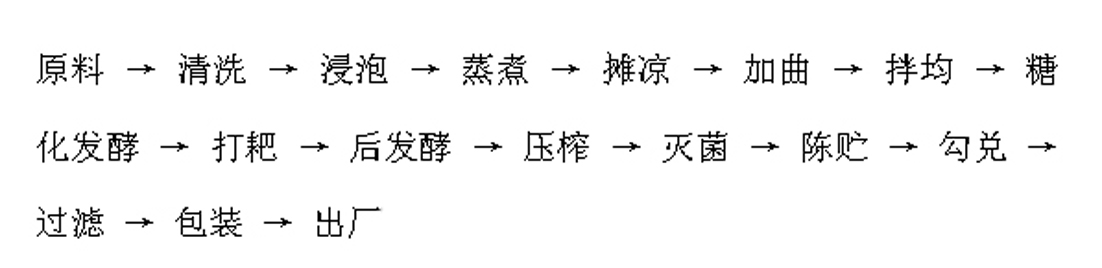

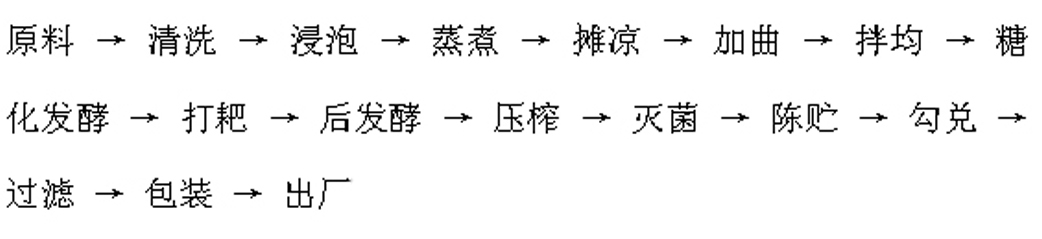

Image

Examples

Embodiment 1

[0021] (1) Ingredients:

[0022] Yellow rice: feeding 250kg, the feeding in the following ingredients refers to yellow rice;

[0023] Mung beans: 3% of the feed, 7.5kg;

[0024] Jujube: 3% of the feed, 7.5kg;

[0025] Ordinary wheat koji or Daqu: 5% of the feed, 12.5kg;

[0026] Bitter beans: use high-quality bitter beans produced in Dai County, Shanxi Province, 0.5% of the input, 1.25kg;

[0027] Active dry yeast: 0.15% of the feed; 0.375kg.

[0028] (2) Process flow:

[0029] 1) Soak yellow rice for more than 12 hours.

[0030] 2) Steaming: It must be steamed, without filling. It is required to steam for 1 hour and then stew the rice. Stew the rice for 1 hour, and stir twice in the middle.

[0031] 3) Cooling: the temperature is controlled below 35°C.

[0032] 4) Add koji, saccharification and fermentation: add koji into the tank, add dry yeast and ordinary wheat koji or Daqu, the specific operation of adding dry yeast is to first weigh 15kg of warm water at about 35°...

Embodiment 2

[0041] (1) Ingredients:

[0042] Yellow rice: feeding 250kg, the feeding in the following ingredients refers to yellow rice;

[0043] Mung beans: 3% of the feed, 7.5kg;

[0044] Jujube: 3% of the feed, 7.5kg;

[0045] Special wheat koji for Fenjiu: use the special wheat koji for Fenjiu produced by Fenjiu Group in Xinghua Village, Shanxi Province, 5% of the input, 12.5kg;

[0046] Bitter beans: use high-quality bitter beans produced in Dai County, Shanxi Province, 0.5% of the input, 1.25kg;

[0047] Active dry yeast: 0.15% of the feed; 0.375kg.

[0048] (2) Process flow:

[0049] 1) Soak yellow rice for more than 12 hours.

[0050] 2) Steaming: It must be steamed, without filling. It is required to steam for 1 hour and then stew the rice. Stew the rice for 1 hour, and stir twice in the middle.

[0051] 3) Cooling: the temperature is controlled below 35°C.

[0052] 4) Add koji, saccharification and fermentation: add koji into the vat, add dry yeast and special wheat koji ...

Embodiment 3

[0061] (1) Ingredients:

[0062] Yellow rice: feeding 250kg;

[0063] Mung beans: 3% of the feed, 7.5kg;

[0064] Jujube: 3% of the feed, 7.5kg;

[0065] Special wheat koji for Fenjiu: 5% of the feed, 12.5kg;

[0066] Bitter beans: use high-quality bitter beans produced in Dai County, Shanxi Province, 0.5% of the input, 1.25kg;

[0067] 61%vol liquor: 50% of the feed, 125kg;

[0068] Active dry yeast: 0.15% of the feed; 0.375kg.

[0069] (2) Process flow:

[0070] 1) Soak the yellow rice for more than 12 hours.

[0071] 2) Steaming: it must be steamed well, without filling, it is required to steam for 1 hour and then stew the rice, stew the rice for 1 hour, and stir twice in the middle.

[0072] 3) Spreading to air: the temperature is controlled below 35°C.

[0073]4) Add koji, saccharification and fermentation: add koji into the vat, add dry yeast and special wheat koji for Fenjiu, the specific operation of adding dry yeast is to first weigh 15kg of warm water at abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com