Porous carbon, and preparation method and applications thereof

A porous carbon, conditioned technology, used in the manufacture of hybrid/electric double-layer capacitors, electrical components, electrolytic capacitors, etc., can solve the problems of poor cycle performance, low capacity, and inability to be widely used in conductive polymers, and achieve a green preparation method. High-capacity, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

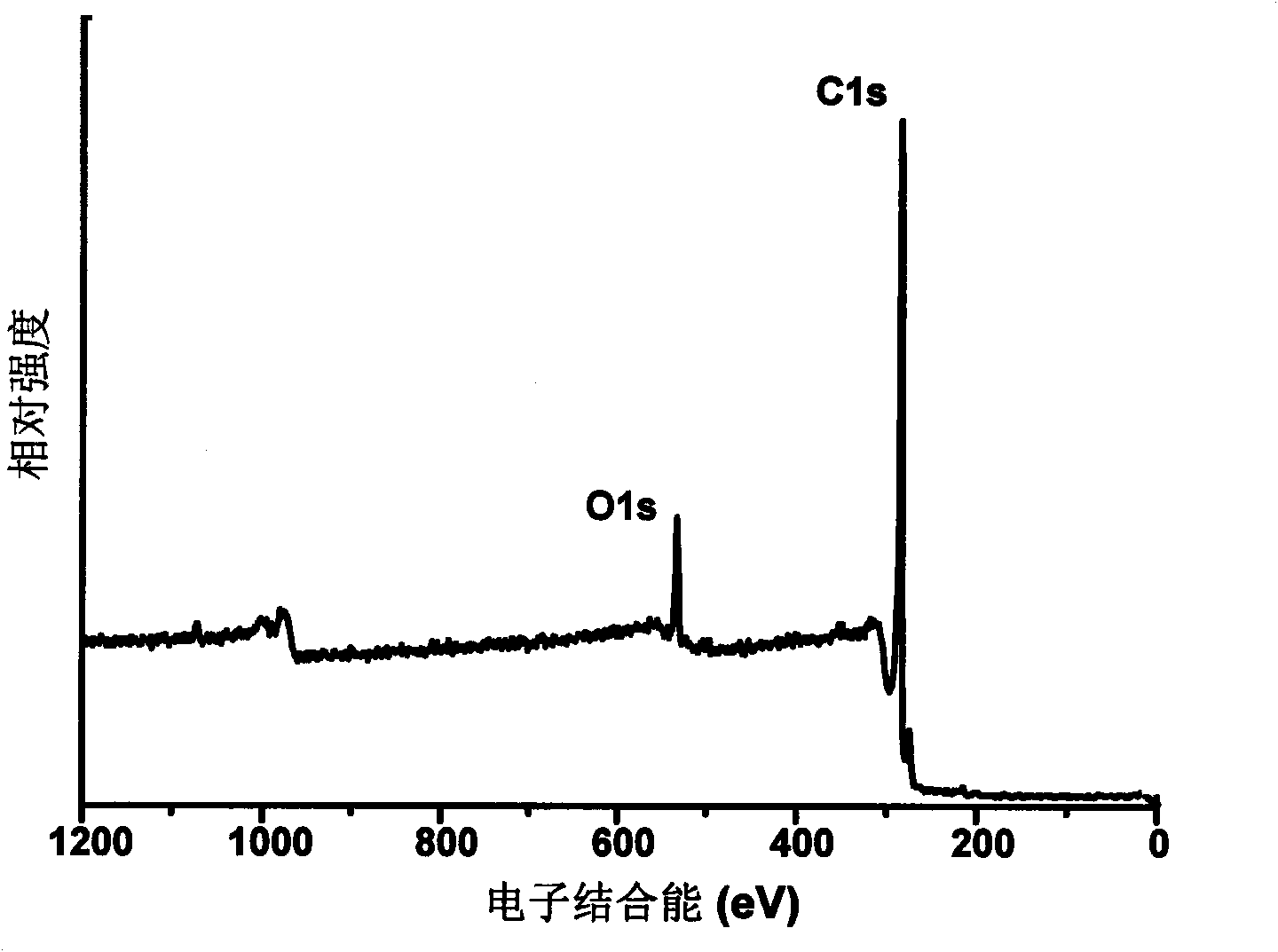

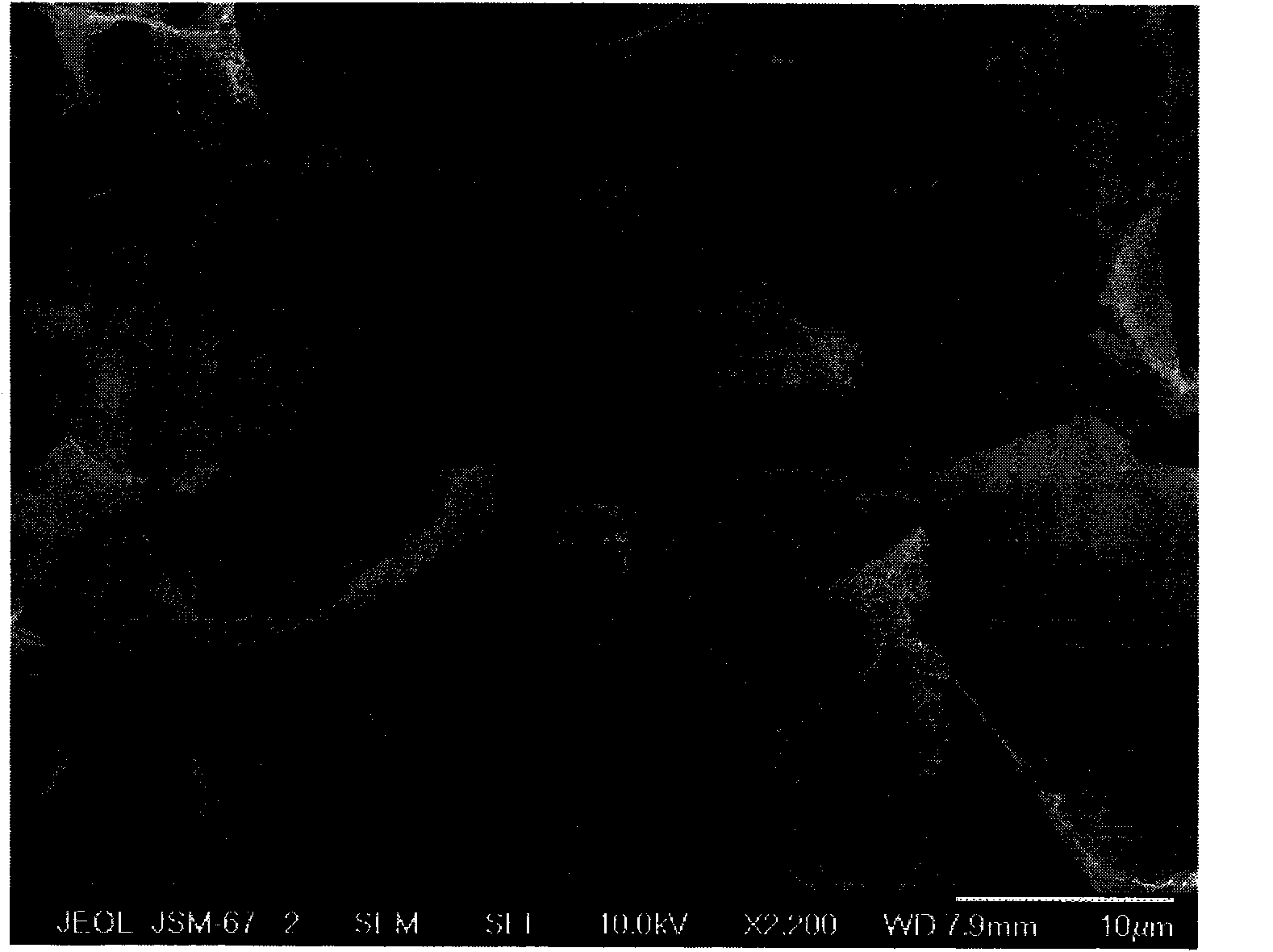

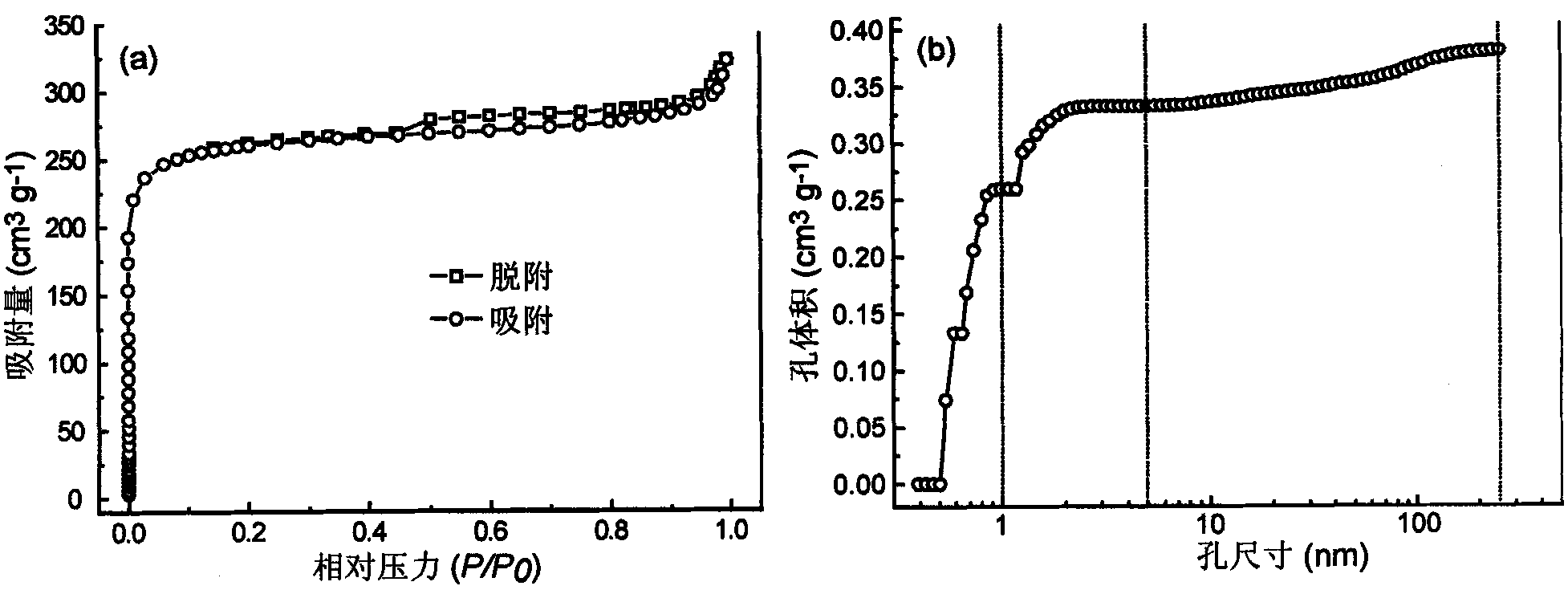

[0032] Embodiment 1, preparation porous carbon

[0033] Weigh 10g alginic acid (purchased from Sinopharm Chemical Reagent Co., Ltd.), place it in a tube furnace, and 2 Under the atmosphere, calcined at 800° C. for 5 hours with a heating and cooling rate of 10° C. / min to obtain a porous carbon precursor. The precursor of the obtained porous carbon was then treated with 1 mol L -1 Hydrofluoric acid was treated at 50°C for 6 hours to obtain wet porous carbon. Finally, the wet porous carbon was dried at 80° C. for 5 hours under vacuum conditions to obtain porous carbon.

Embodiment 2

[0034] Embodiment 2, preparation porous carbon

[0035] Weigh 8g of lithium alginate (made by reacting equimolar alginic acid (purchased from Sinopharm Chemical Reagent Co., Ltd.) with lithium hydroxide (purchased from Beijing Chemical Reagent Company)) and 6g of sodium alginate (purchased from Sinopharm Chemical Reagent Co., Ltd.), mixed evenly, placed in a tube furnace, and calcined at 600°C for 6 hours under an Ar atmosphere, with a heating and cooling rate of 20°C / min, to obtain a precursor of porous carbon. The resulting porous carbon precursor was then treated with water at 25 °C for 6 hours to obtain wet porous carbon. Finally, the wet porous carbon was dried in air at 100° C. for 5 hours to obtain porous carbon.

Embodiment 3

[0036] Embodiment 3, preparation porous carbon

[0037] Weigh 4g of alginic acid (purchased from Sinopharm Chemical Reagent Co., Ltd.), 3g of magnesium alginate (made by reacting equimolar sodium alginate (purchased from Sinopharm Chemical Reagent Co., Ltd.) with magnesium chloride) and 3g of calcium alginate (with Equimolar sodium alginate (purchased from Sinopharm Group Chemical Reagent Co., Ltd.) reacted with calcium chloride) was mixed evenly and placed in a tube furnace. 2 In an atmosphere with a volume ratio of :Ar of 1:1, calcining at 900° C. for 4 hours, with a heating and cooling rate of 5° C. / min, to obtain a precursor of porous carbon. Then the obtained precursor of porous carbon was mixed with 5mol·L -1 Nitric acid was treated at 80 °C for 3 hours to obtain wet porous carbon. Finally, the wet porous carbon in N 2 Dry at 80°C for 6 hours to obtain porous carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com