Flame-retardant porous polymer film and preparation method thereof

A porous polymer and polymer technology, which is applied in the field of flame retardant, can solve the problems of poor flame retardancy, uneven distribution and easy agglomeration of films, and achieve uniform flame retardancy and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

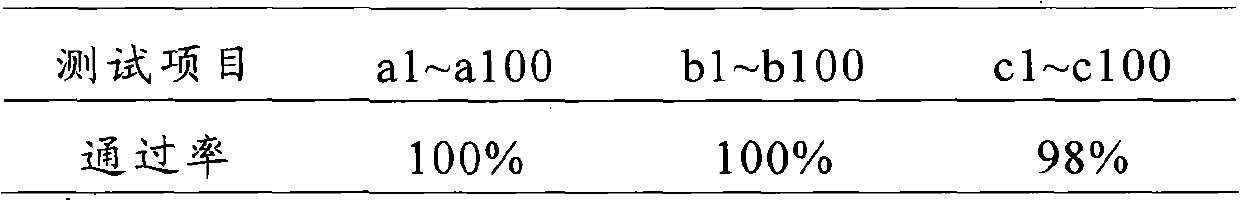

Examples

preparation example Construction

[0010] The embodiment of the present invention discloses a preparation method of a flame-retardant porous polymer film, comprising:

[0011] a. After dissolving the polymer with an organic solvent, add a pore-forming agent to obtain an emulsion;

[0012] b. Applying the emulsion obtained in step a to the substrate, drying or extracting, to obtain a porous polymer base film;

[0013] c. After coating the surface of the porous polymer base film obtained in step b with an aluminum hydroxide film and then heating, the aluminum hydroxide on the surface of the substrate is thermally decomposed to generate alumina, and a flame-retardant porous polymer film is obtained.

[0014] Steps a to b prepare porous polymer-based membranes by inversion method, wherein the polymer is preferably polyvinylidene fluoride (PVDF), polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) and polyacrylonitrile (PAN) One or more, because the above-mentioned polymers not only have good high temperature re...

Embodiment 1

[0032] 1. Mix 5g PVDF and 10g PVDF-HFP respectively and dissolve them in 80g tetrahydrofuran solution, add 5g ethanol, stir well to obtain emulsion.

[0033] 2. Spray the emulsion obtained in step 1 on the surface of the positive electrode sheet of the battery and then dry it to obtain a porous polymer base film.

[0034] 3. Immerse the porous polymer base film obtained in step 2 into 30wt% Na 3 PO 4 After the solution is dried, the dried porous polymer base film is immersed in 30wt% alum solution and dried, and an aluminum hydroxide film is formed on the surface of the porous polymer, and the film is heated to 135° C. to obtain a flame-retardant porous polymer film.

Embodiment 2

[0036] 1. Dissolve 5g of PVDF and 10g of PVDF-HFP in 80g of tetrahydrofuran, add 5g of dibutyl phthalate and stir evenly to obtain an emulsion.

[0037] 2. Spray the emulsion obtained in step 1 on the surface of the PE non-woven membrane and then dry it to obtain a polymer base film.

[0038] 3. Extracting the polymer-based membrane obtained in step 2 with methanol to obtain a porous polymer-based membrane.

[0039] 4. Immerse the porous polymer base film obtained in step 3 into 20wt% Al 2 (SO 4 ) 3 After solution drying, the dried porous polymer-based membrane was immersed in 50 wt% NaAlO 2 After the solution is dried, an aluminum hydroxide film is formed on the surface of the porous polymer, and the film is heated to 135° C. to obtain a flame-retardant porous polymer film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com