Engine body

A body and cavity technology, applied in the field of the body, can solve the problems of noise reduction, vibration absorption effect, noise reduction, vibration absorption effect, stress concentration, etc., to prolong the fatigue life of the body, fatigue life of the vibration absorption body, heat expansion and contraction deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

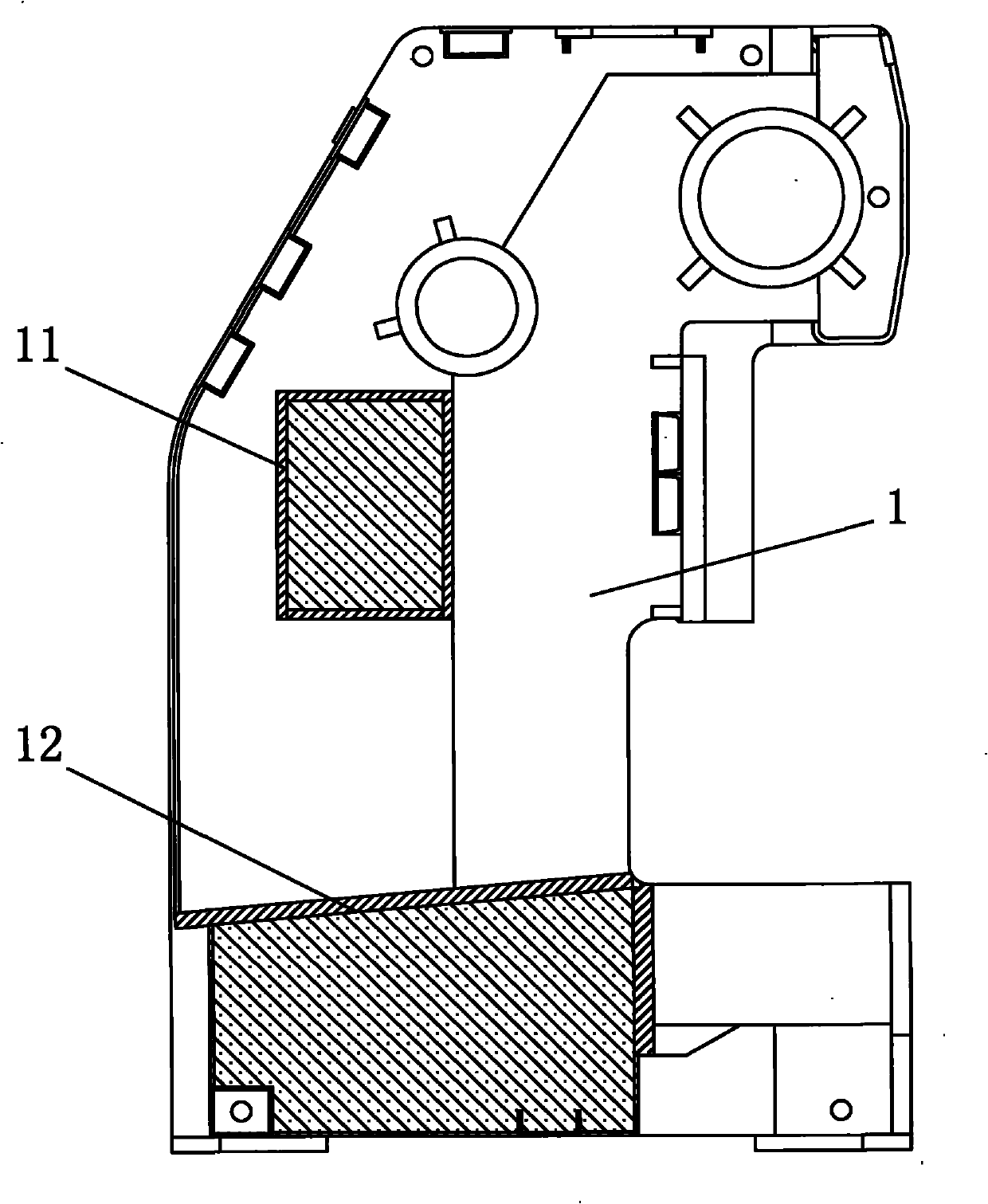

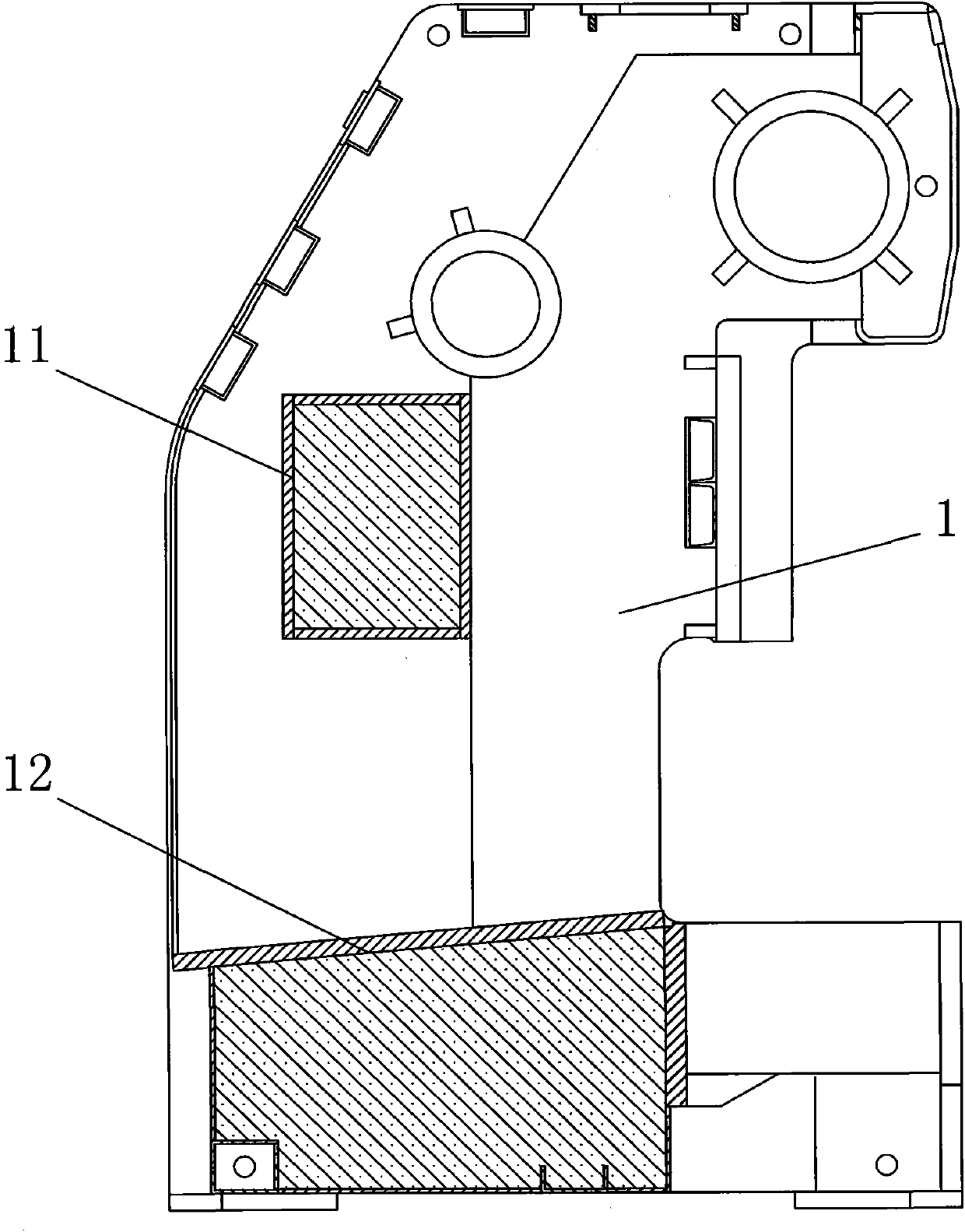

[0017] Such as figure 1 The shown body includes a body 1, and the body 1 is provided with two closed cavities 11, 12, and the cavities 11, 12 are filled with elastic gel-like counterweight fillers, and the body is a welded body , The cavities 11, 12 are welded metal plates to form cavities. The weight filler is a uniform mixture of barite powder and viscous solution. In this embodiment, the viscous solution is commercially available water glass glue, containing 30% to 40% by mass of sodium silicate, and the fineness of the barite powder is a commercially available product above 200 mesh, containing sulfuric acid The mass percentage of barium is more than 95%, the mass ratio of water glass glue and barite powder is 4:1, after mixing evenly, pour it into the cavity of the welding machine body and seal it. After half a year of trial and use at a relatively high ambient temperature of 50°C to 60°C, the machine has good noise reduction and vibration absorption effects and has goo...

Embodiment 2

[0019] A machine body includes a body. The body is provided with two closed cavities filled with elastic gel-like counterweight fillers. The body is a welded body, and the cavities are made by welding metal plates. The weight filler is a uniform mixture of barite powder and viscous solution. In the present embodiment, the viscous solution is unsaturated polyester resin (vinyl), the fineness of the barite powder is a commercially available product above 325 mesh, and the barium sulfate mass percentage is more than 95%. The mass ratio of polyester resin and barite powder is 3:1, and after being mixed evenly, it is poured into the cavity of the welding machine body and sealed. After half a year of trial and use at a relatively high ambient temperature of 50°C to 60°C, the machine has good noise reduction and vibration absorption effects and has good stability.

Embodiment 3

[0021] A body, including a body, the body is provided with two semi-closed cavities (that is, vents are left), the cavities are filled with elastic gel-like counterweight fillers, the body is a welded body, and the cavity is Metal sheets are welded to form the cavity. The weight filler is a uniform mixture of barite powder and viscous solution. In the present embodiment, the viscous solution is unsaturated polyester resin (vinyl), the fineness of the barite powder is a commercially available product above 300 mesh, and the barium sulfate mass percentage is more than 95%. The mass ratio of polyester resin and barite powder is 5:1, and after mixing evenly, pour it into the cavity of the welding machine body and seal it. After half a year of trial and use at a relatively high ambient temperature of 50°C to 60°C, the machine has good noise reduction and vibration absorption effects and has good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com