Vortex high pressure water jet water mist generating device

A high-pressure water jet and generating device technology, which is applied in the direction of spraying devices, spraying devices, spraying devices with movable outlets, etc., can solve the problems of not being able to carry out large-scale operations, large power consumption, and small atomization area, and improve work efficiency. Efficiency and fogging quality, simple structure, sensitive and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

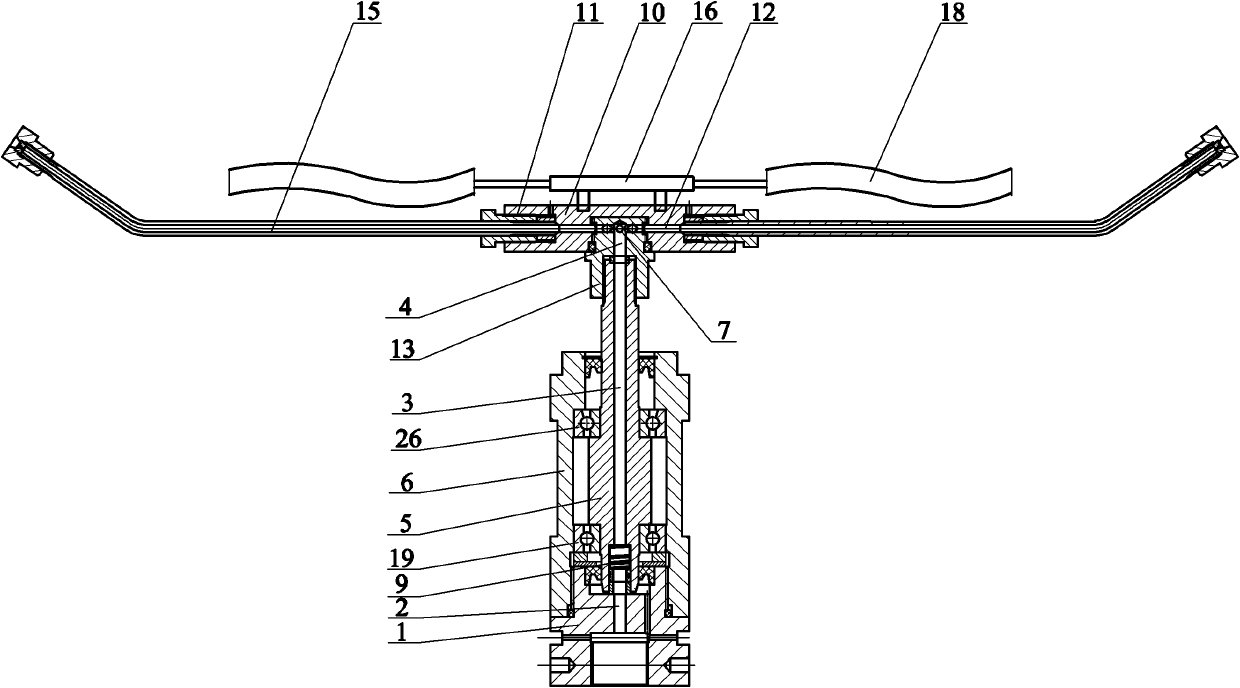

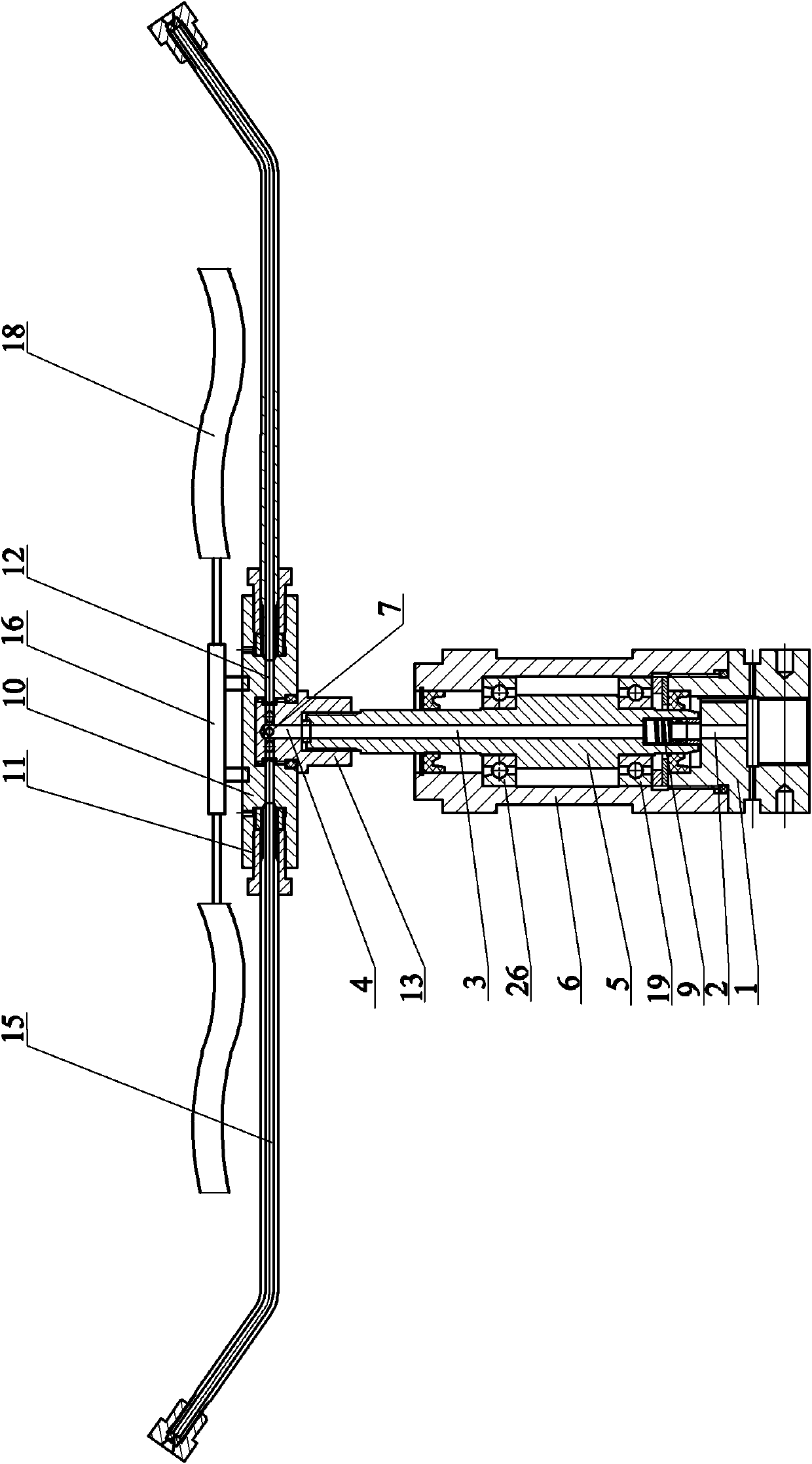

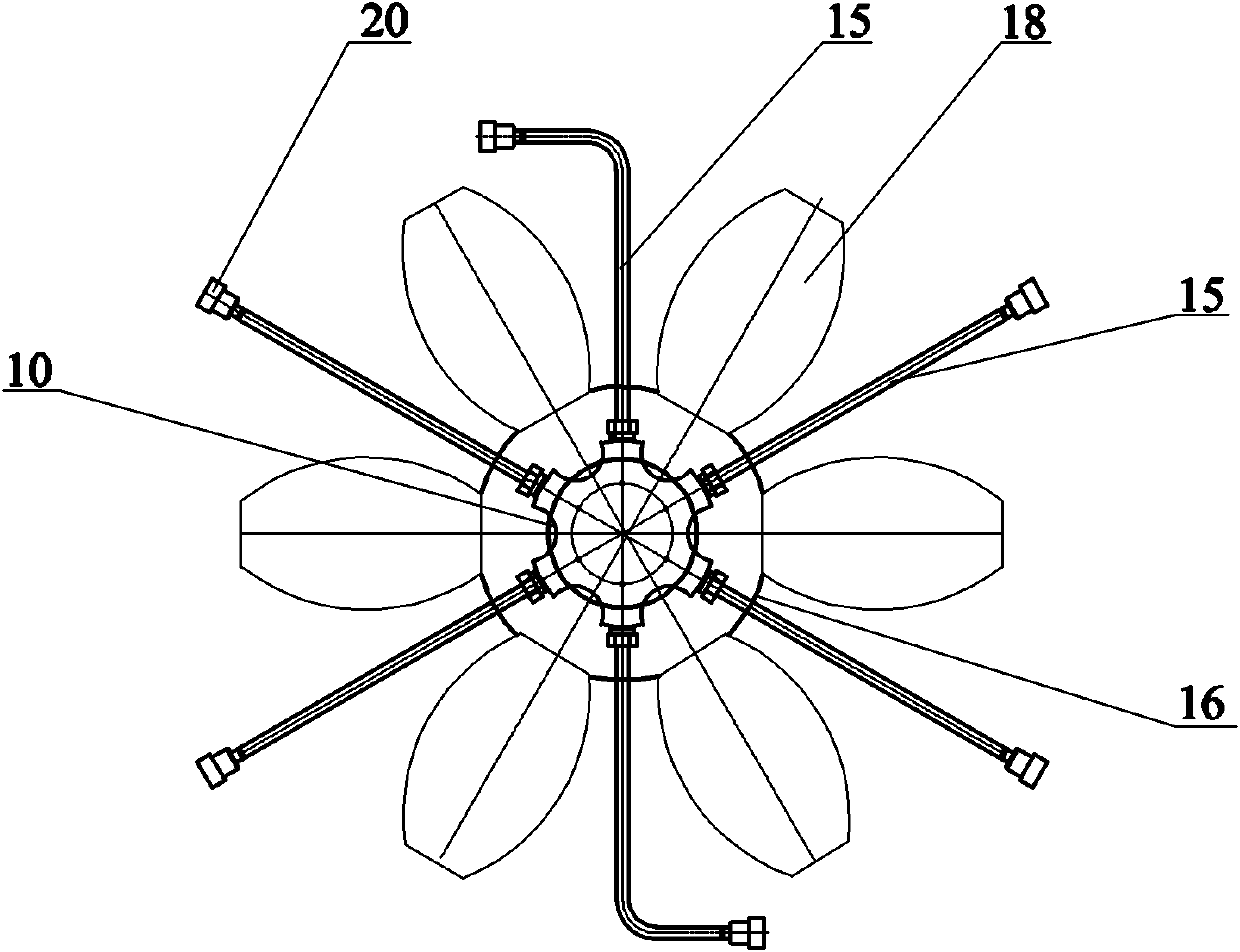

[0019] Such as figure 1 As shown, the vortex high-pressure water jet fine water mist generating device includes a rotating body 1, a rotating shaft 5 and a bearing seat 6, a liquid inlet hole 2 is provided in the rotating body 1, and a hole 2 is provided in the rotating shaft 5 along its axial direction. There is a rotating shaft inner hole 3, and the bearing seat 6 is fixed on the rotating body 1. The rotating shaft 5 is installed in the bearing seat 6 through the upper bearing 26 and the lower bearing 19 to rotate and seal, between the bottom end of the rotating shaft 5 and the rotating body 1 There is an elastic sealing mechanism between them, and the top end of the rotating shaft 5 is fixedly equipped with a split body 13, and a split main hole 4 is opened in the split body 13 along its axial direction, and a split branch is opened in the split body 13 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com