Backing plate under anchorage for post-tensioning method

A technology of under-anchor backing plate and post-tensioning method, which is applied to bridge parts, structural elements, bridges, etc., can solve the problems of under-anchor backing plate breakage, scrapped concrete components, and non-compact concrete, etc., achieving scientific structural design and improving quality , The effect of eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

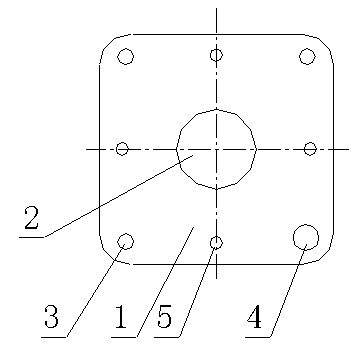

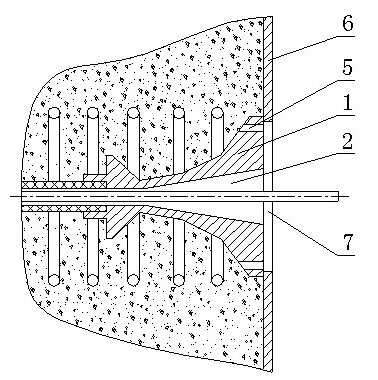

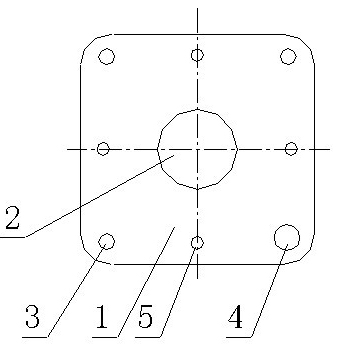

[0013] figure 1 It is the front view of the backing plate under the post-tensioning anchor of the present invention, figure 2 It is a schematic diagram of the structure of the backing plate under the post-tensioning method of the present invention in use, as shown in the figure. The post-tensioning anchor base plate is provided with a central hole 2 in the middle of the anchor base plate 1, and the anchor base plate 1 is provided with three installation and fixing holes 3 and a grouting hole 4, and the upper anchor base plate 1 , down, left and right and four overflow holes 5 symmetrically distributed relative to the center hole 2, the axis distance of the overflow holes 5 from the center hole 2 is less than the radius of the steel strand perforation 7 of the template 6, that is, the template The edge of the steel strand perforatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com