Control method of concrete pouring compactness for anchor backing plate by post-tensioning method

The technology of the backing plate under the anchor and the control method is applied in the direction of manufacturing tools, ceramic molding machines, etc., which can solve the problems of difficult control of the concrete vibration compactness, rupture of the anchor bottom plate, scrapping of the concrete components, etc., and achieve the vibration compactness Science, improve quality, avoid the effect of being crushed and cracked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

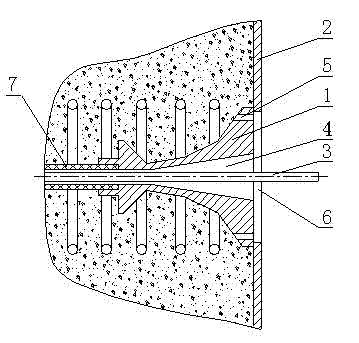

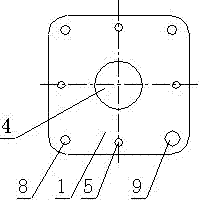

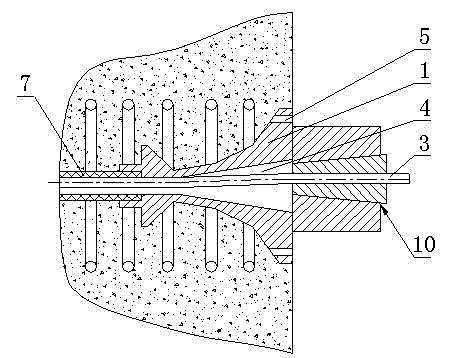

[0015] figure 1 For adopting the method of the present invention to carry out the structural representation of vibrating compactness control, figure 2 It is the front view of the backing plate under the anchor, as shown in the figure. The method for controlling the pouring density of the backing plate under the post-tensioning method is to pre-embed the bellows 7, and use the inner hole of the bellows 7 as a prestressed tension hole; The middle part of the lower backing plate 1 is provided with a central hole 4, and four overflow holes 5 are symmetrically and evenly distributed on the upper, lower, left and right sides of the anchor lower backing plate 1 relative to the central hole 4, and the anchor lower backing plate 1 is also provided with The bolt holes 8 and the grouting holes 9 are installed on the formwork 2 through bolt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com