Method for controlling concrete compactness at T-shaped beam deformation section of reinforced concrete prestress

A control method and prestressing technology, applied to bridges, manufacturing tools, bridge parts, etc., can solve problems such as easy formation of cavities, difficulty in concrete blanking, scrapping of T-beams, etc., and achieve scientific improvement in surface finish and vibration compactness , Improve the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

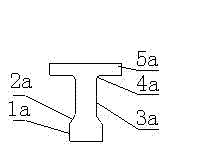

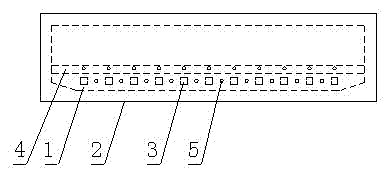

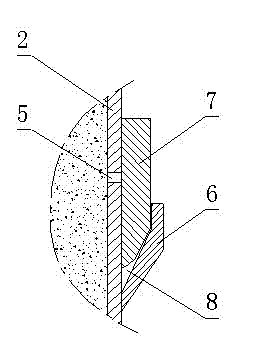

[0018] figure 2 It is a schematic diagram of the structure of the plate vibrator and overflow holes arranged on the formwork, as shown in the figure. The method for controlling the concrete compactness of the deformed section of the reinforced concrete prestressed T-beam comprises horizontally distributing a plurality of plate vibrators 3 ( figure 2 Only eleven flat-plate vibrators are drawn in ), a plurality of overflow holes 5 are horizontally distributed on the formwork 2 corresponding to the lower rib area 4 of the T-shaped beam deformation section, and a plurality of overflow holes 5 are horizontally distributed on the formwork 2 corresponding to the horseshoe section 1 of the T-shaped beam. And an overflow hole 5 is also provided between two adjacent plate vibrators 3, figure 2 A total of twenty-one overflow holes 5 are dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com