Method for catalyzing polymer with multi-metallic catalyst to compound carbon nano-tube in situ

A polymetallic catalyst and carbon nanotube technology, applied in the field of preparation of nanotubes, can solve the problems of complex process, equipment corrosion and high cost, and achieve the effects of simple preparation process, mild reaction conditions and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

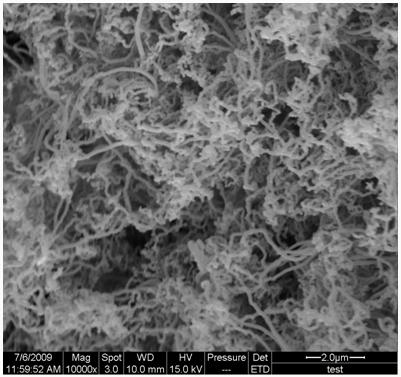

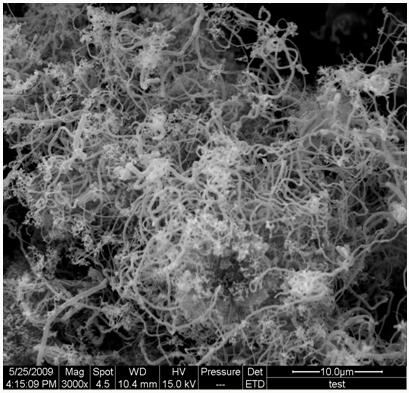

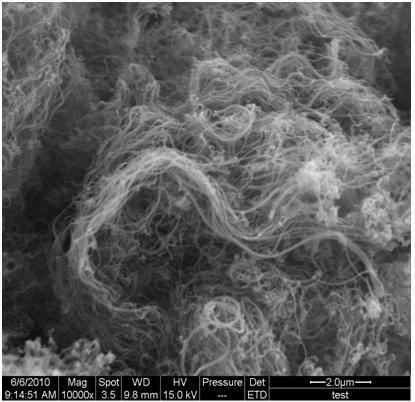

[0011] Specific embodiment 1: In this embodiment, the method for in situ synthesis of carbon nanotubes using polymetallic catalysts to catalyze polymers is carried out according to the following steps: 1. According to the ratio of parts by weight, 50 to 99.5 parts of polyolefin and 0.5 to 50 Mix one part of polymetallic catalyst uniformly at the melting temperature of polyolefin to obtain a mixture; 2. Add the mixture obtained in step 1 into a quartz tube, and then crack under nitrogen protection at 450°C to 750°C until no gas is generated , that is, carbon nanotubes (see Figure 1 to Figure 4 ).

[0012] The char formation rate of the method in this embodiment is more than 40%; more than 99% of the char is carbon nanotubes.

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the polymer described in step one is polyethylene, polypropylene, polypropylene grafted with maleic anhydride, ethylene-octene copolymer, ethylene-butylene ethylene copolymer, ethylene-hexene copolymer, ethylene propylene rubber, EPDM rubber, polystyrene, polyisobutylene, polybutadiene, natural rubber, acrylonitrile-butadiene-styrene copolymer, acrylonitrile - One or a combination of two ethylene-styrene copolymers; or waste recycling of the above materials. Other steps and parameters are the same as in the second embodiment.

[0014] When the polymer described in this embodiment is a mixture, the two polymers are mixed in any ratio.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the multi-metal catalyst described in step one is a metal oxide alloy of nickel, magnesium and molybdenum, or nickel, magnesium and molybdenum supported on a carrier metal oxide alloys. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com