Screen printing back glue process and its special screen

A screen printing, self-adhesive technology, which is applied in the self-adhesive process and its special screen field, can solve the problems of health hazards, environmental pollution, and difficulty in compliance, and can reduce the mold release time and reduce the cost of Good quality production and guaranteed adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

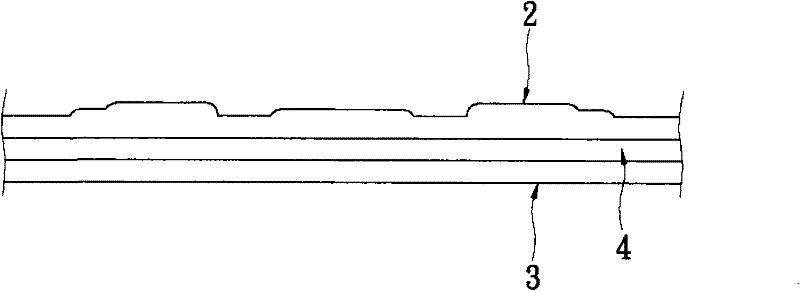

[0029] see Figure 1 to Figure 3 , the present invention provides a screen-printing gumming process, which utilizes screen printing to produce gumming, and uses OMTC (Out Mold Thermoformed Compound, which can be called make-up gluing or out-of-mold lamination) to replace traditional spray paint and stickers Carry out the performance of product characteristics.

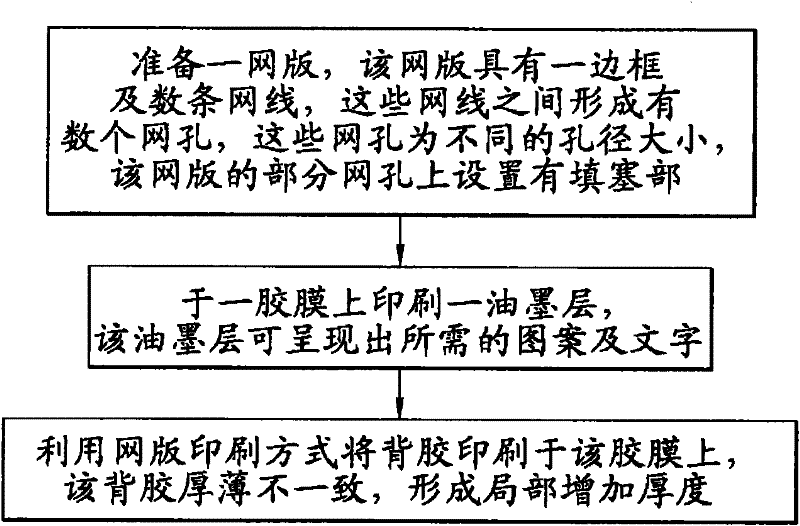

[0030] Such as figure 1 As shown, the screen-printing type back glue process of the present invention comprises steps as follows:

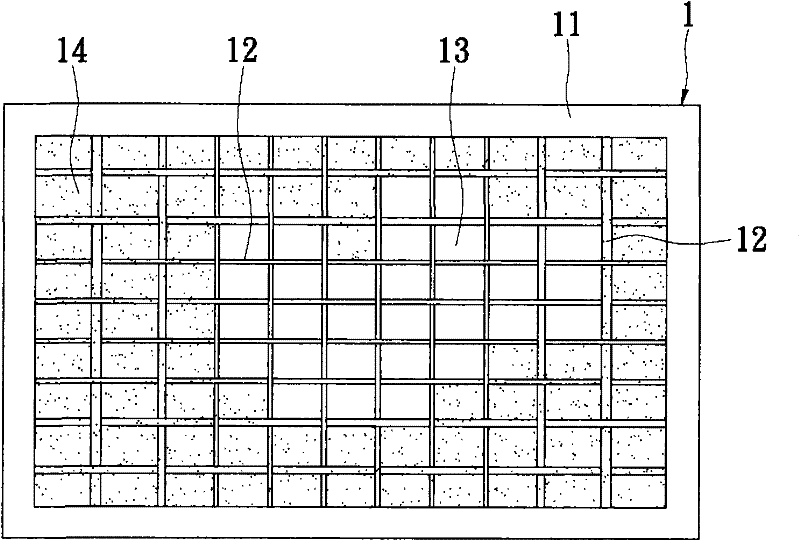

[0031] (1) Prepare one-screen version 1 (such as figure 2 As shown), the screen 1 has a frame 11 and several mesh wires 12 arranged inside the frame 11. These mesh wires 12 are arranged in a criss-cross pattern, that is, these mesh wires 12 include warp threads and weft threads, so that these mesh wires 12 Several mesh holes 13 are formed between them. The mesh cables 12 can be made of materials such as nylon and cotton silk, but the materials for making the mesh cables 12 are not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com