Steel back leveling die

A leveling and mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor leveling effect, high production cost, large randomness, etc., and achieve reasonable and practical structural design, stable shape and size, Ingenious and novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

[0026] see Figure 1-Figure 6 :

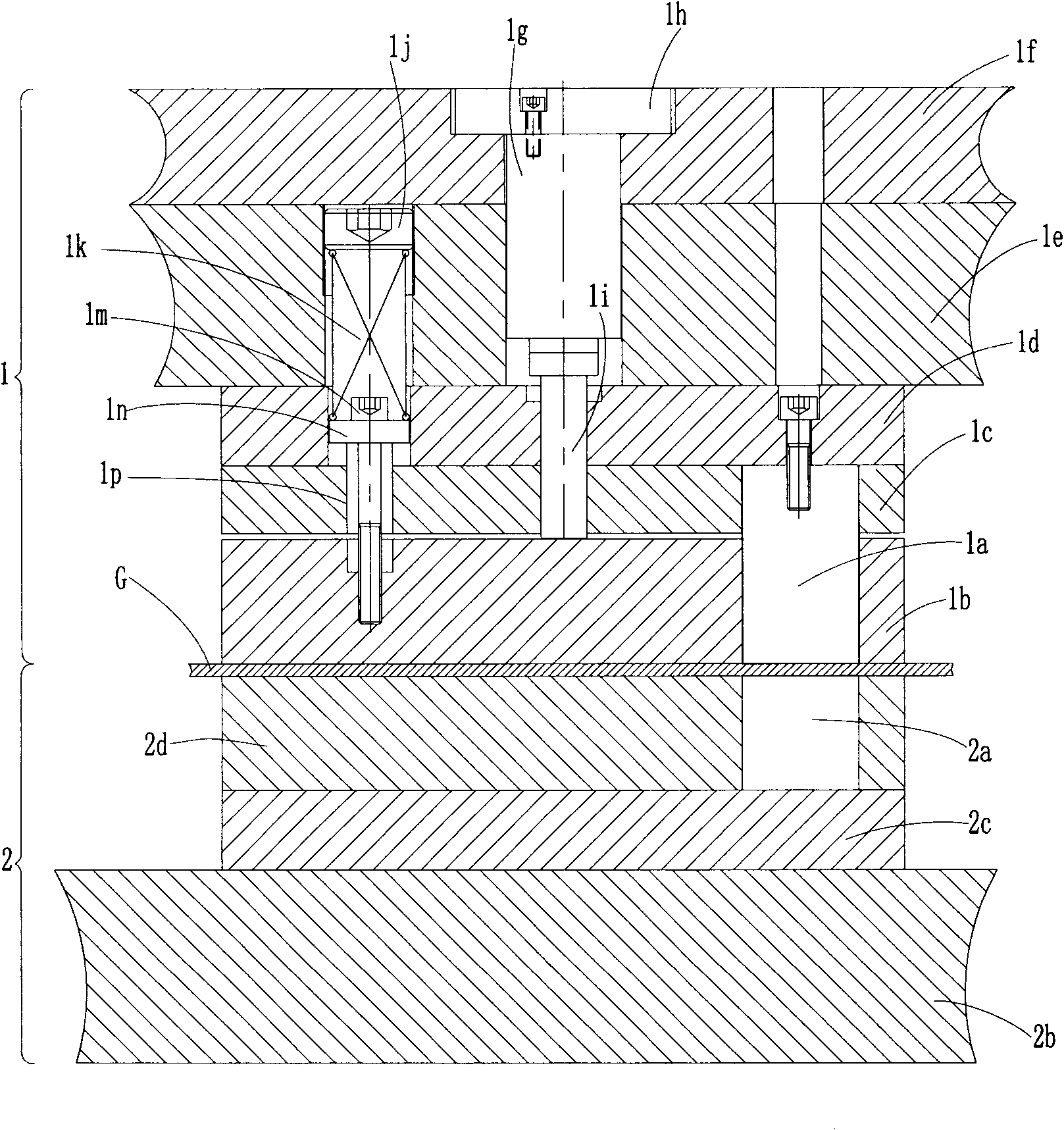

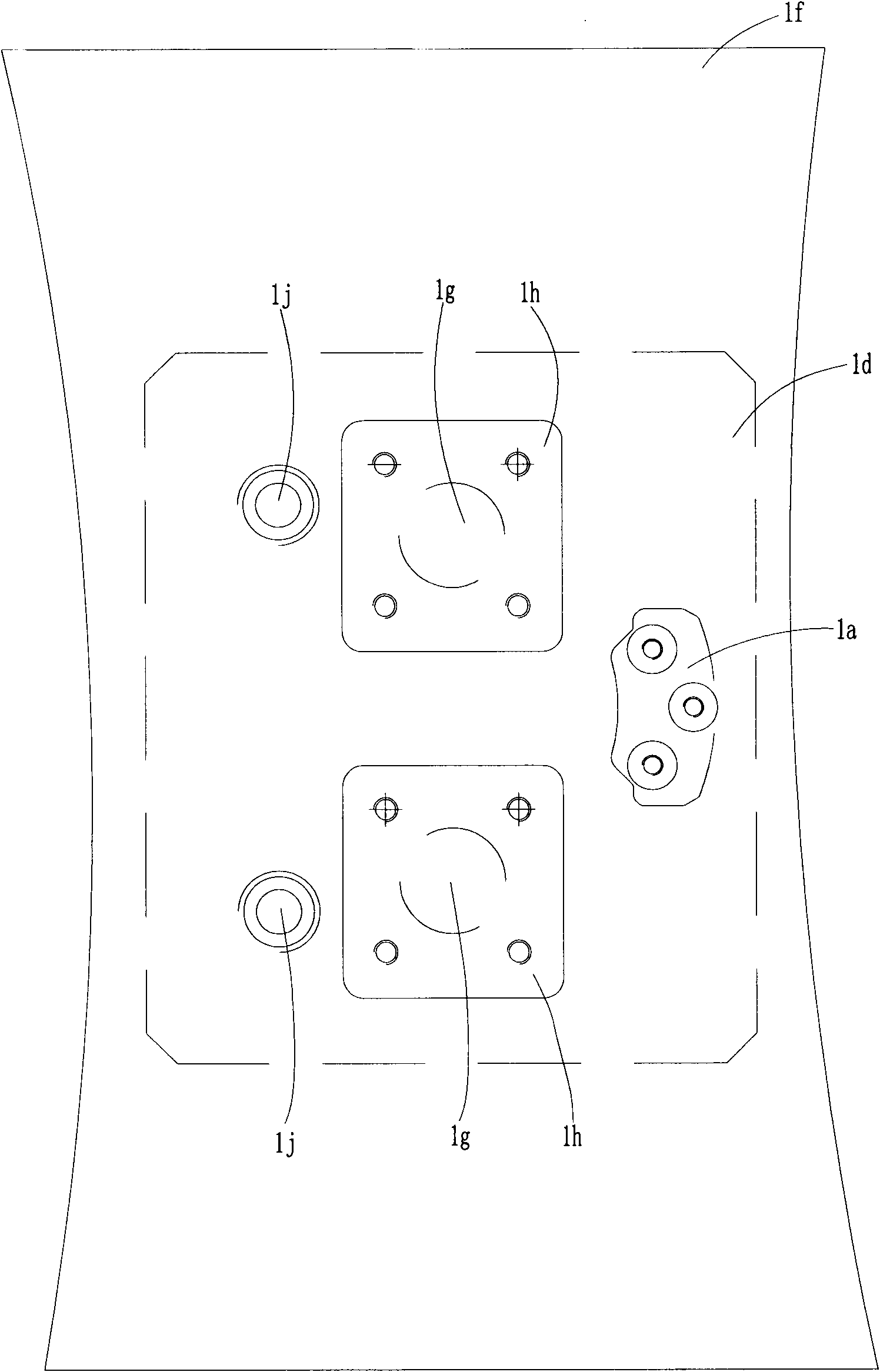

[0027] The mold includes a leveling punch 1 provided with an upper leveling block 1a, and a leveling die 2 provided with a lower leveling block 2a.

[0028] The leveling punch 1 includes the unloading plate 1b, the punch fixing plate 1c, the upper backing plate 1d, the upper template 1e, the upper clamping template 1f, the punch fixing plate 1c, and the unloading plate 1b arranged horizontally from bottom to top. There is a gap between them, and the punch fixing plate 1c, the upper backing plate 1d, the upper template 1e, and the upper clamping template 1f are sequentially stacked and connected.

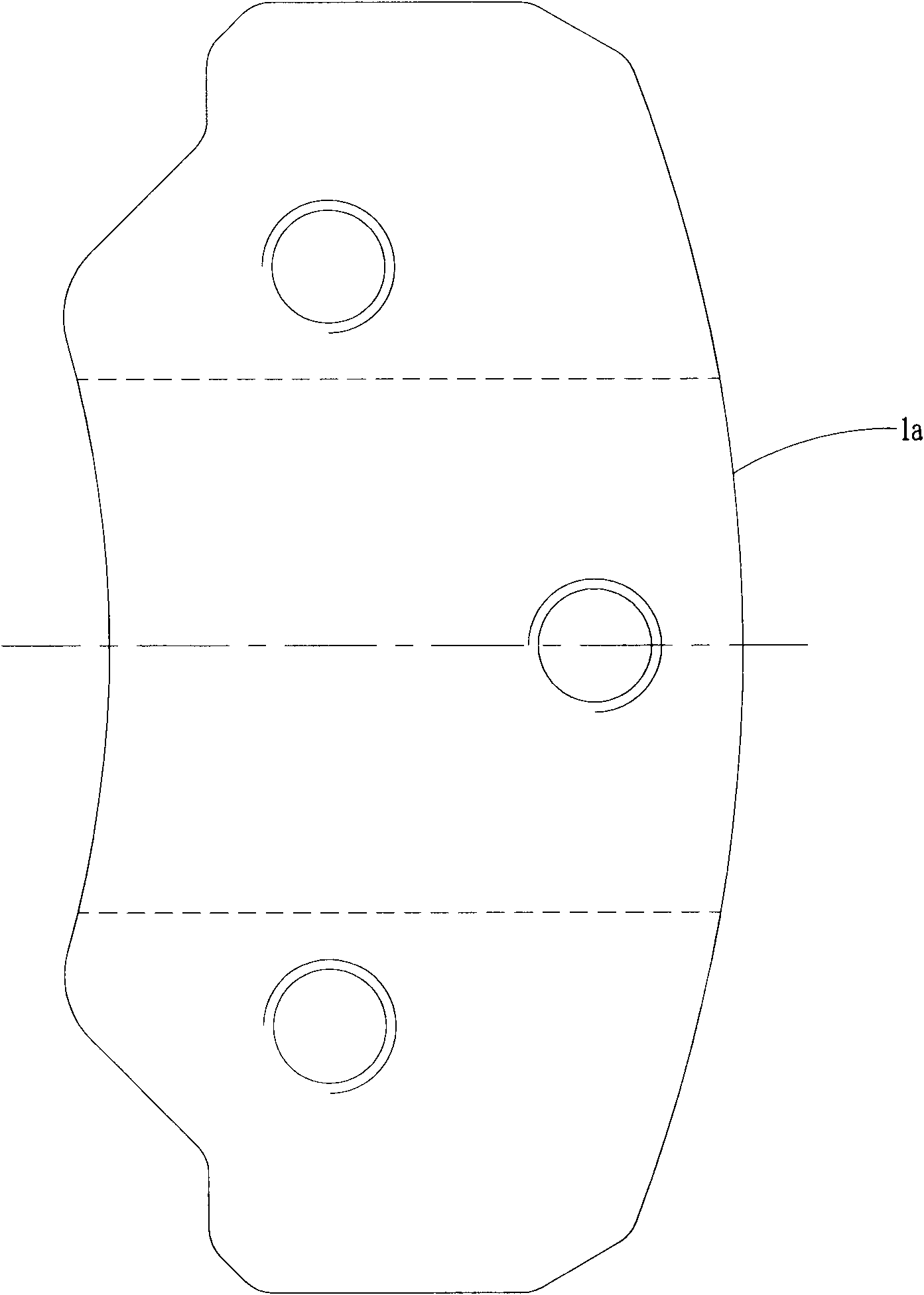

[0029] The upper leveling block 1a is vertically installed in the punch fixing plate 1c and the stripping plate 1b and fixedly connected with the upper backing plate 1d by fasteners. The working surface of the upper lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com