Single piston hydraulic free-piston engine capable of reducing pumping flow pulsation

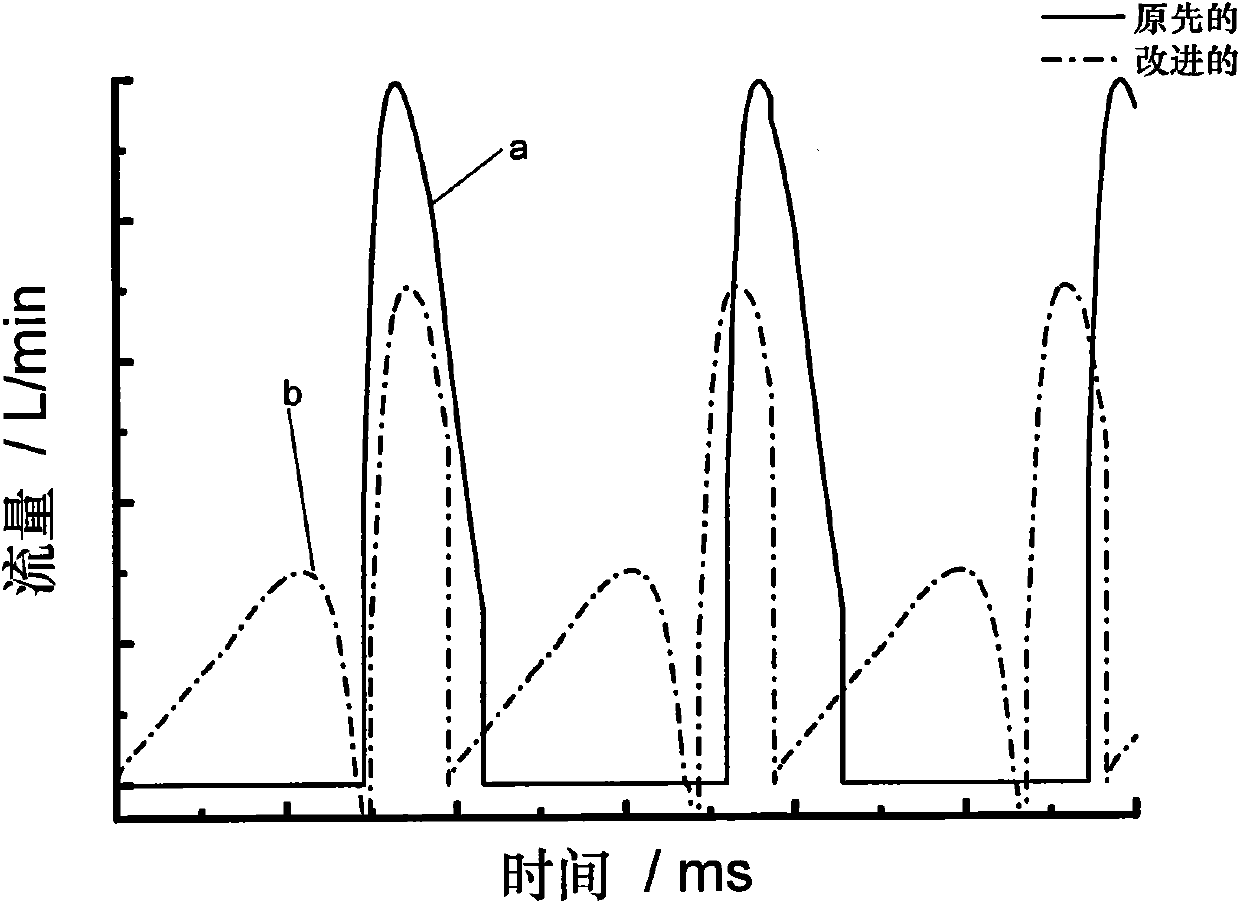

A piston engine and single-piston technology, applied in the field of piston engines, can solve the problems of increasing the complexity of the system structure and control, reducing the power-to-weight ratio of the engine, and increasing the weight space of the system, so as to improve the utilization rate and reduce the Flow pulsation, to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

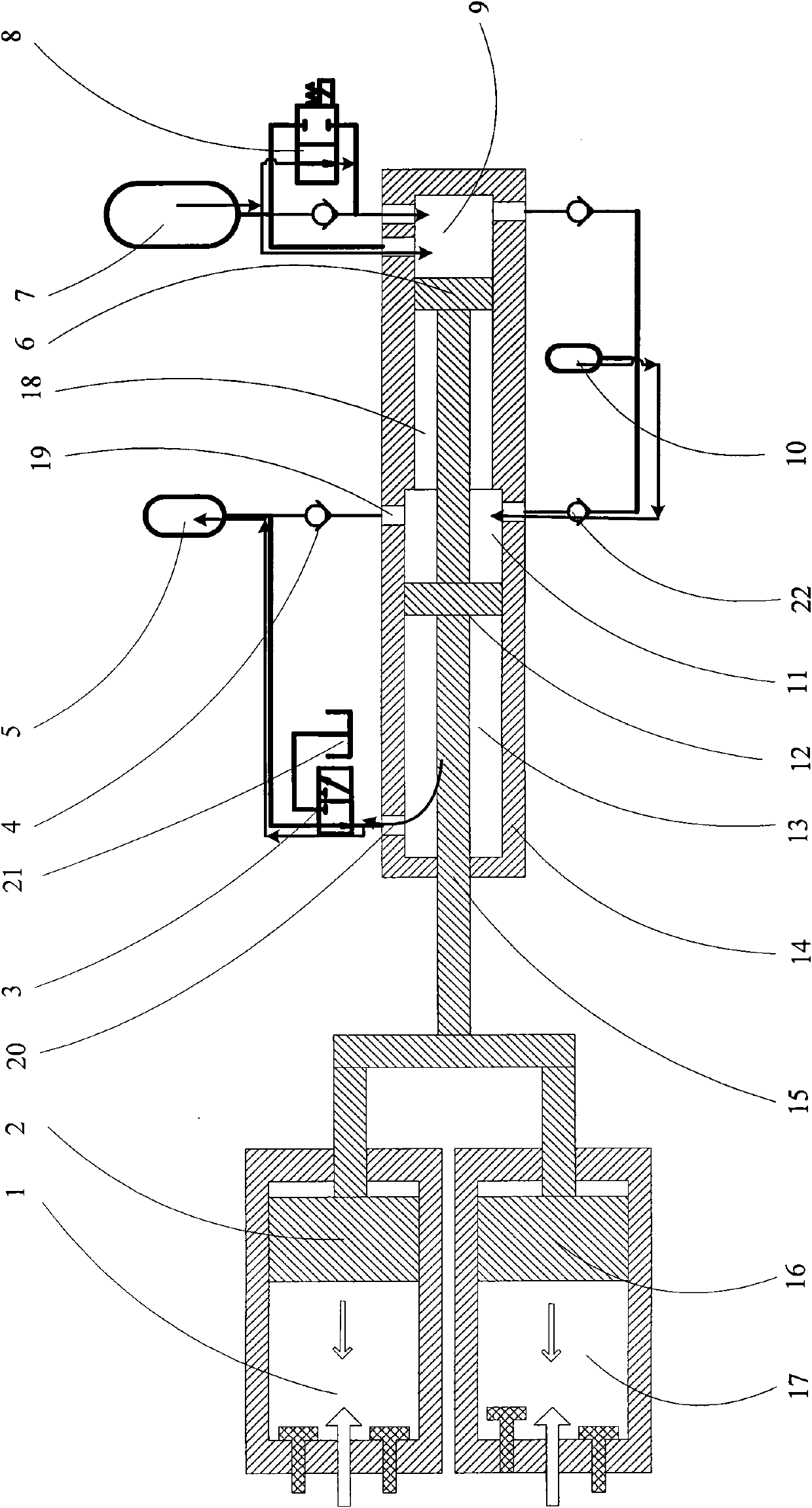

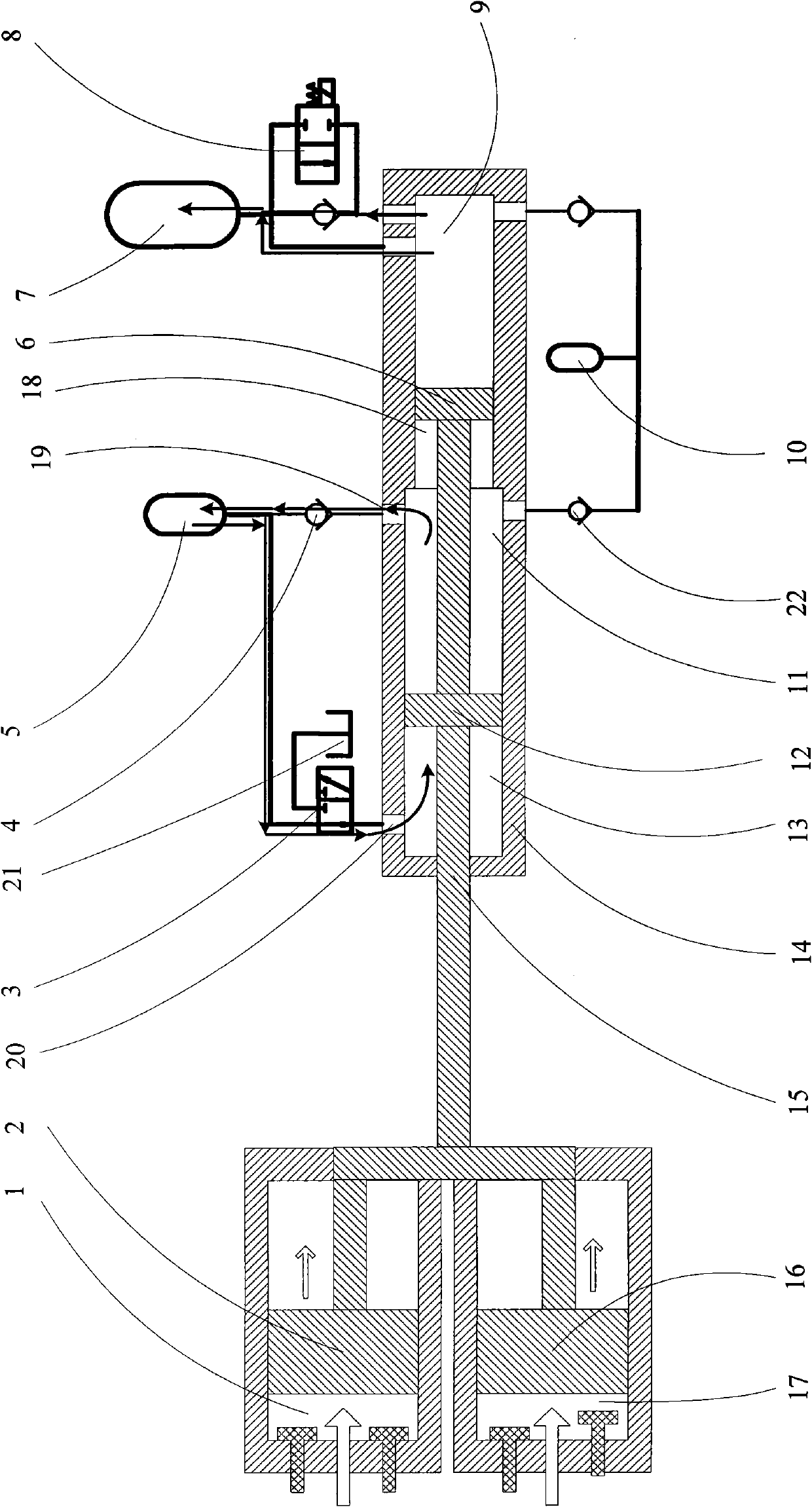

[0017] as attached figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the present invention comprises a hydraulic cylinder block 14, a two-cylinder in-line cylinder block, a high-pressure accumulator 5, a flow regulating valve 3, a low-pressure oil tank 21, and a first power piston 2, a second power piston 16, a compression piston 6 1. A free piston assembly composed of hydraulic pump piston 12 and piston rod 15. Wherein, the two-cylinder in-line cylinder block is a two-cylinder four-stroke cylinder block; the first power piston 2 and the second power piston 16 are respectively placed in the two cylinder bodies of the two-cylinder in-line cylinder block and the first power piston 2 and the The end face of the second power piston 16 is in the same vertical plane, the first power piston 2 and the second power piston 16 are fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com