Cold-transfer printing thickener, printing paste thereof and preparation method thereof

A technology of cold transfer printing and printing color paste, applied in the field of printing and dyeing industry, which can solve the problems of poor rheological properties of modified starch, loss of viscosity, sensitive color paste to shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

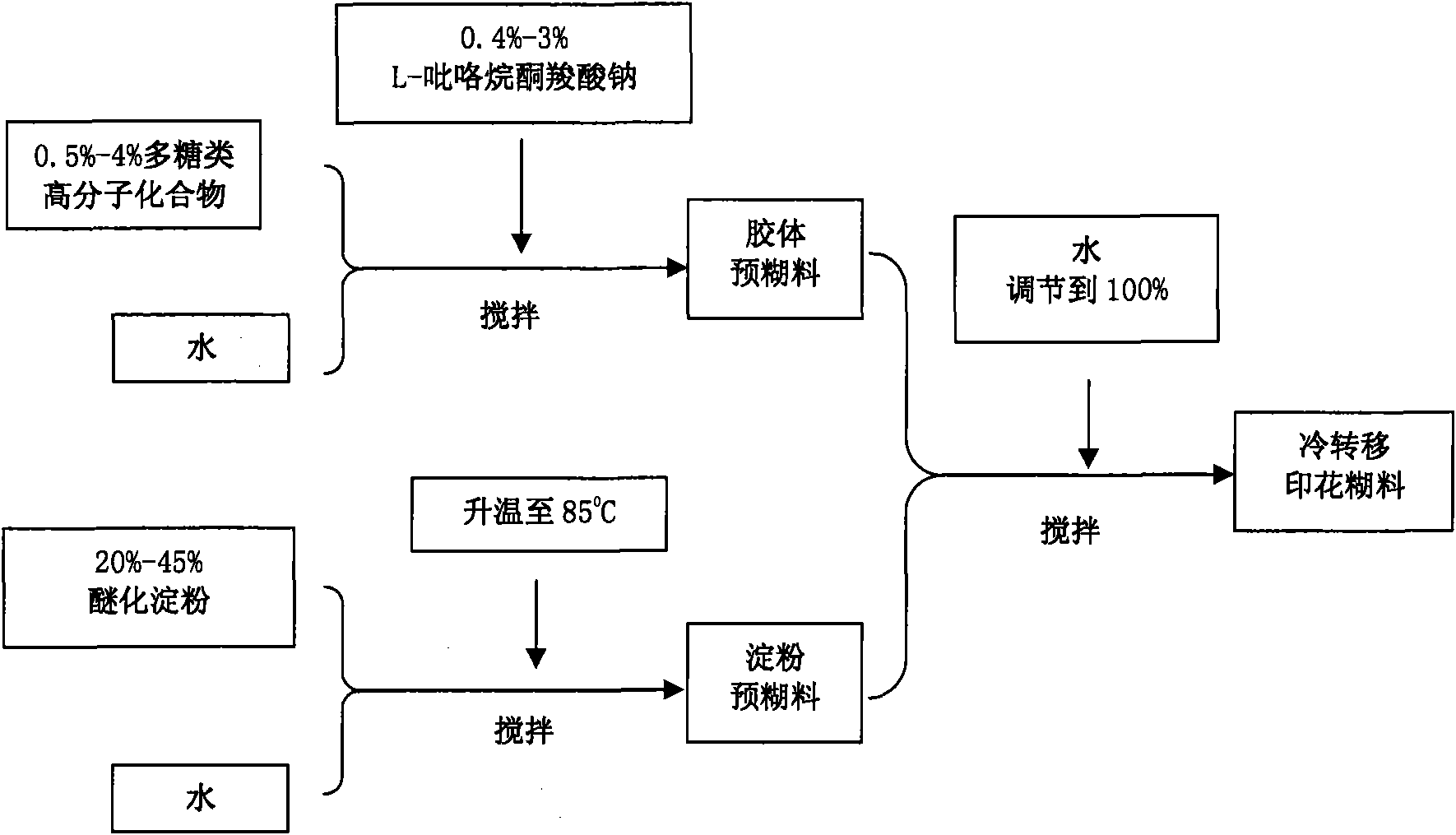

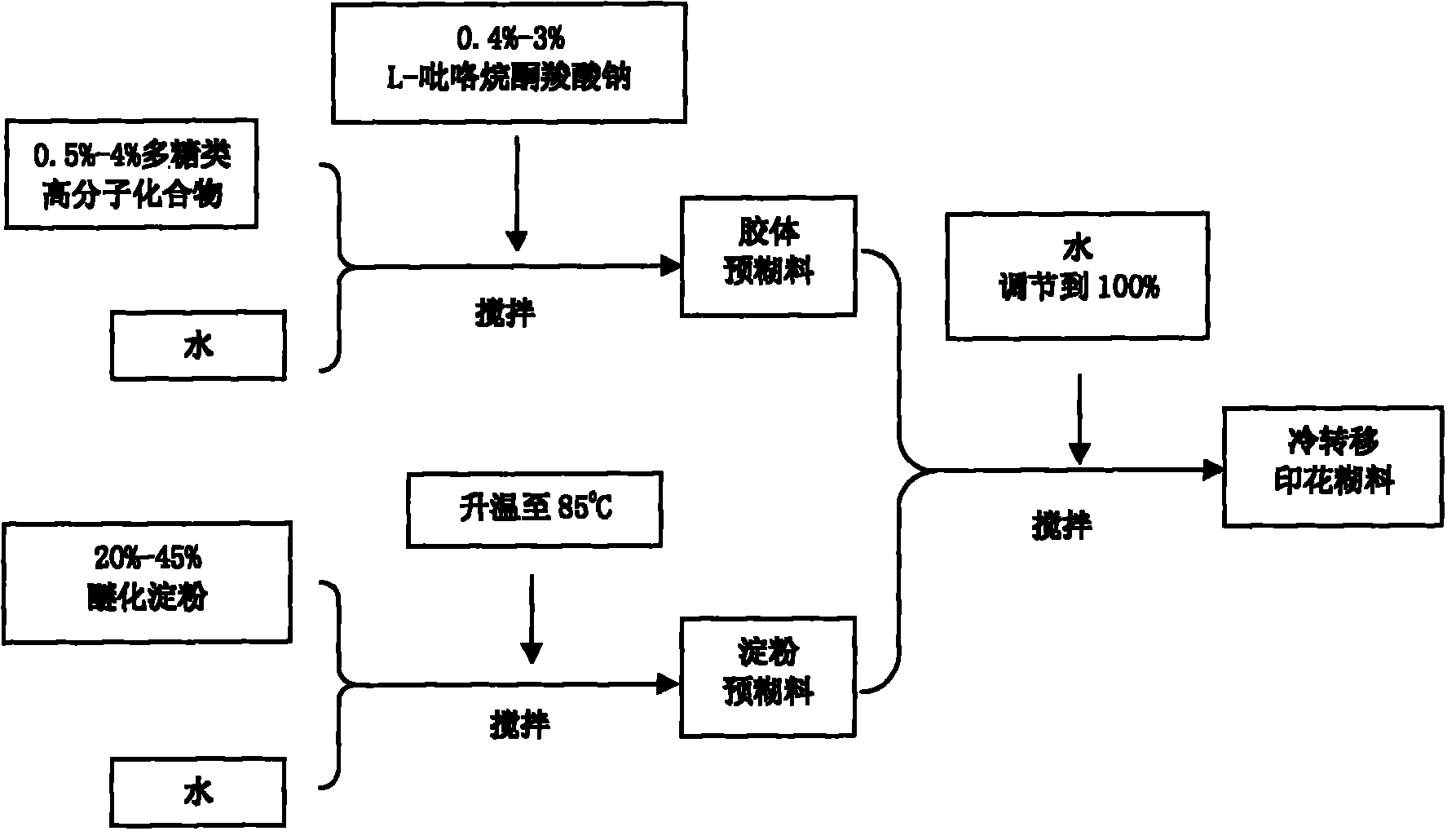

[0108] Embodiment 1, the preparation of cold transfer printing paste

[0109] Recipe composition:

[0110] xanthan gum is 2%,

[0111] Sodium L-pyrrolidone carboxylate 1%,

[0112] Etherified starch is 28%,

[0113] Adjust to 100% with distilled water.

[0114] See also the preparation method figure 1 Flow chart of cold transfer printing paste synthesis process. Specifically, in distilled water, xanthan gum accounting for 2% of the total weight percentage of the cold transfer printing paste is placed in a stirrer, and stirred for 2 hours at a temperature of 70°C and 1400-2800r / min. Slowly add 1% L-pyrrolidone sodium carboxylate (PCA-Na) accounting for the total weight percentage of the cold transfer printing paste, and mix uniformly to form a colloidal prepaste for use. In distilled water, the low-viscosity etherified starch accounting for 28% of the total weight percentage of the cold transfer printing paste is placed in a reaction kettle, and the temperature is raise...

Embodiment 2

[0115] Embodiment 2, the preparation of cold transfer printing paste

[0116] Recipe composition:

[0117] Xanthan gum is 0.5%,

[0118] Sodium L-pyrrolidone carboxylate 0.4%,

[0119] Etherified starch is 45%,

[0120] Adjust to 100% with distilled water.

[0121] See also the preparation method figure 1 Flow chart of cold transfer printing paste synthesis process. Specifically, in distilled water, xanthan gum accounting for 0.5% of the total weight percentage of the cold transfer printing paste is placed in a stirrer, and stirred for 2 hours at a temperature of 70°C and 1400-2800r / min. Slowly add 0.4% of sodium L-pyrrolidone carboxylate (PCA-Na) accounting for the total weight percentage of the cold transfer printing paste, and mix uniformly to form a colloidal prepaste for use. In distilled water, the low-viscosity etherified starch, which accounts for 45% of the total weight percentage of the cold transfer printing paste, is placed in a reaction kettle, and the tem...

Embodiment 3

[0122] Embodiment 3, the preparation of cold transfer printing paste

[0123] Recipe composition:

[0124] 3.5% guar gum,

[0125] Sodium L-pyrrolidone carboxylate 3%,

[0126] Etherified starch is 20%,

[0127] Adjust to 100% with distilled water.

[0128] See also the preparation method figure 1 Flow chart of cold transfer printing paste synthesis process. Specifically, in distilled water, the guar gum that accounts for 3.5% of the total weight percentage of the cold transfer printing paste is placed in a stirrer, and stirred for 2 hours at a temperature of 70 ° C and 1400 to 2800 r / min. Slowly add 3% L-pyrrolidone sodium carboxylate (PCA-Na) accounting for the total weight percentage of the cold transfer printing paste, mix evenly, and form a colloidal prepaste for use. In distilled water, the low-viscosity etherified starch accounting for 20% of the total weight percentage of the cold transfer printing paste is placed in a reaction kettle, and the temperature is ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com