Device and method for smelting iron by low-grade limonite ore

A technology for iron ore and ore, which is applied to the field of low-grade limonite iron smelting equipment, can solve the problems of scaling gas pipelines, easy occurrence of danger, gas ignition, etc., and achieves good environmental protection, investment saving and small investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples. The top of the hot blast stove 12 is provided with a chimney 8, and the top of the chimney 8 is provided with a chimney cover 9;

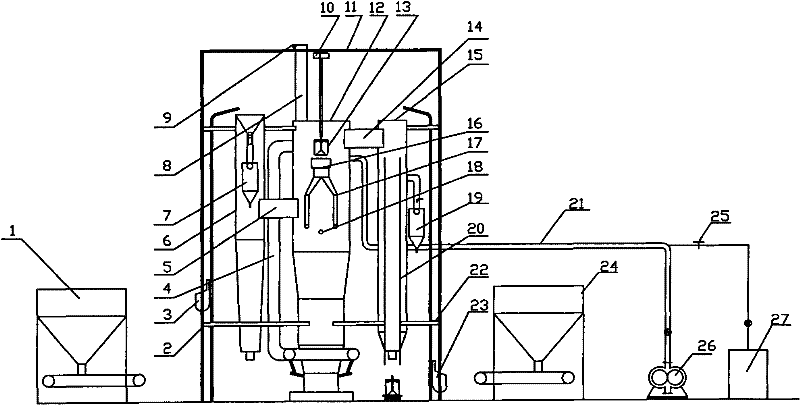

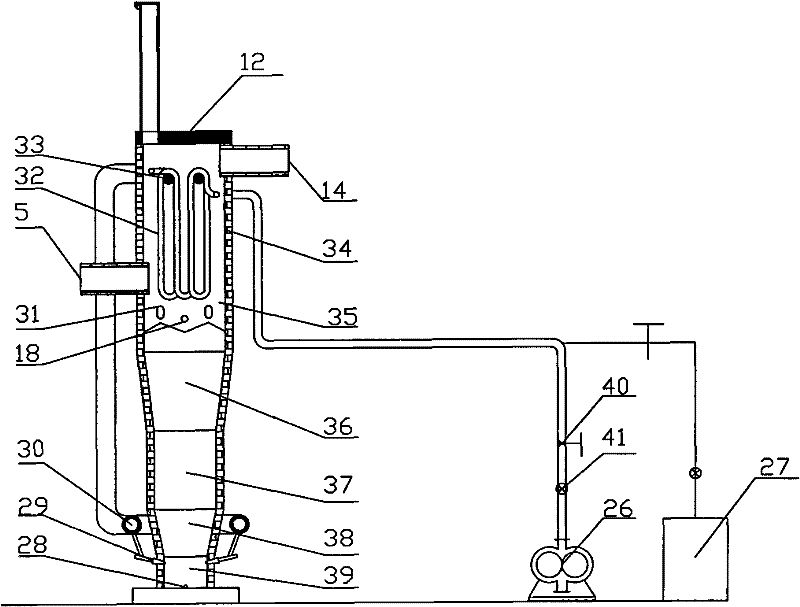

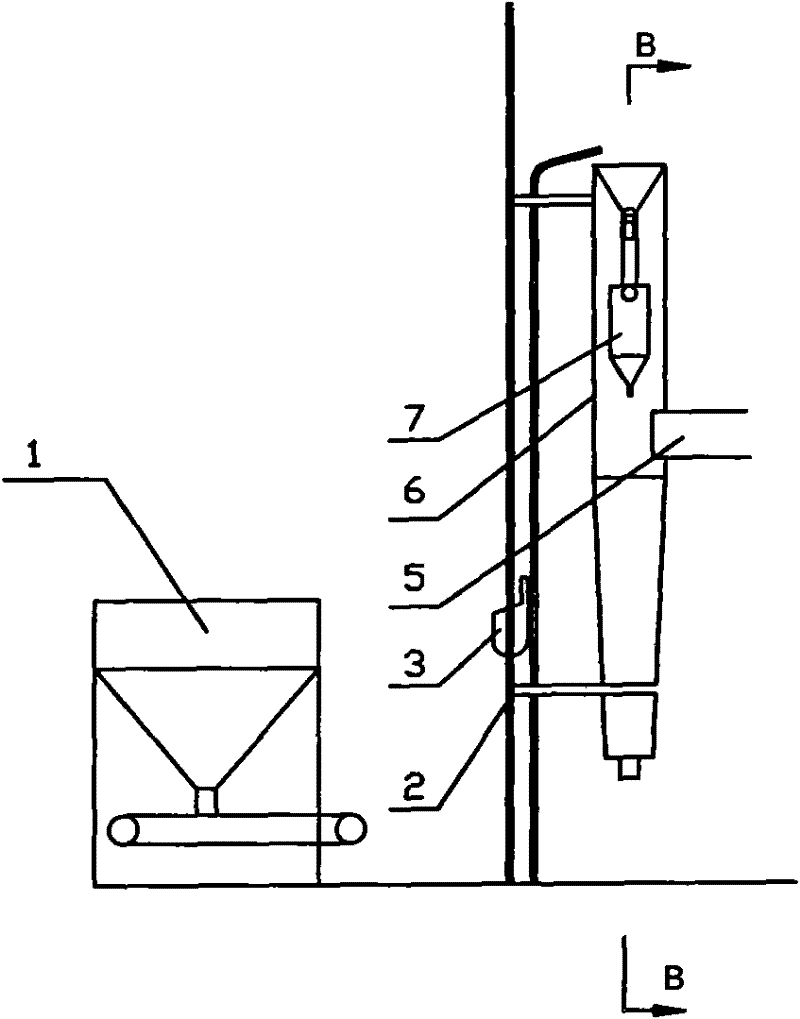

[0040] like figure 1 , 2 As shown, a kind of low limonite ore ironmaking device comprises hot blast stove 12, ore roasting furnace 15, limestone calciner 6, air blower 26 and feeding device; Hot blast stove 12 preferably adopts heat exchange type hot blast stove; Hot blast stove The body of heater of 12 is built by bricks 34 of hot blast stove. Below the furnace waist 37 of the hot blast stove 12 of the present invention is basically the same as a common blast furnace, including a furnace belly 38, a furnace hearth 39, an iron taphole 28, and slag iron treatment facilities. The part above furnace waist 38 has been improved. From bottom to top, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com