Microbe generating antifungal lipopeptid and preparation method and application of antifungal lipopeptid thereof

An antifungal and microbial fermentation technology, applied in the biological field, can solve problems such as drug resistance of pathogenic fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

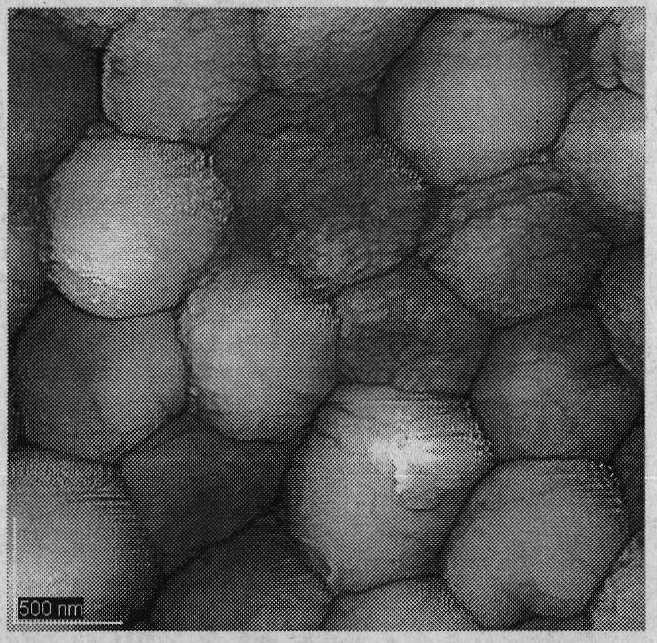

Image

Examples

Embodiment 1

[0061] (1) Cultivation of microbial strains and fermentation of antifungal lipopeptides

[0062] [Broth medium (g / L): peptone 10.0, beef extract 5.0, NaCl 5.0, pH 7.2; solid medium needs to add 20.0 agar.

[0063] YEPD medium (g / L): peptone 20.0, yeast powder 10.0, glucose 20.0; solid medium needs to add 20.0 agar. ] Here, the known content can be deleted.

[0064] The composition of the slant and seed medium: (g / L): glucose 3, tryptone 5, yeast extract powder 6, NaCl6, deionized water preparation, pH 7.5; solid medium needs to add 15g agar powder.

[0065] Composition of fermentation medium (g / L): 5 g of sugary material (glucose), 15 g of nitrogen source (ammonium nitrate), 1 g of sodium citrate, MgSO 4 .7H 2 0, 0.5g, K 2 HPO 4 2~6g, KH 2 PO 4 5g, pH 7.0-7.2. The sterilization temperature of the seed medium and the fermentation medium is 115°C for 20 minutes.

[0066] The strain BI1 was inoculated from a slant into a 250 mL Erlenmeyer flask filled with 50 mL of seed ...

Embodiment 2

[0068] (1) The fermentation strain used is CGMCC No.3412, and the composition of the fermentation medium is (g / L): glucose 10g, nitrogen source 20g, sodium citrate 3g, MgSO 4 ·7H 2 0, 0.2g, K 2 HPO 4 2g, KH 2 PO 4 3g, pH 7.0;

[0069] (2) Fermentation culture: Insert the cultured seeds into the fermentation medium at an inoculum size of 2% (v / v), the culture temperature is 30°C, and the fermentation ventilation volume is 5m 3 / h, tank pressure 0.03MPa, stirring speed 80 rev / min, fermentation time 30 hours, feed sterile air during fermentation, maintain the pH of the fermentation broth at 7.5 with ammonia water, the sterilization temperature of the seed medium and the fermentation medium is 121°C, 20min. The output of antifungal lipopeptide in the fermentation broth was 1.5g / L.

Embodiment 3

[0071] (1) The fermentation strain used is CGMCC No.3412, and the composition of the fermentation medium is (g / L): corn flour 35, nitrogen source peptone 15, sodium citrate 1, MgSO 4 ·7H 2 0, 0.8, K 2 HPO4 4 , KH 2 PO 4 6, pH 7.2.

[0072] (2) Fermentation culture: Insert the cultured seeds into the fermentation medium at an inoculum size of 2% (v / v), the culture temperature is 30°C, and the fermentation ventilation volume is 5m 3 / h, tank pressure 0.05Pa, stirring speed 60 rpm, fermentation time 45h, feed sterile air during the fermentation process, maintain the pH of the fermentation broth with ammonia water at 7.2, and the output of antifungal lipopeptide in the fermentation broth is 1.4g / L .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com