Vehicular oxygen-containing gasoline prepared from crude methylal and component oil and preparation method thereof

A technology of methylal and component oils, which is applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., and can solve problems such as low calorific value, easy water absorption and stratification, and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

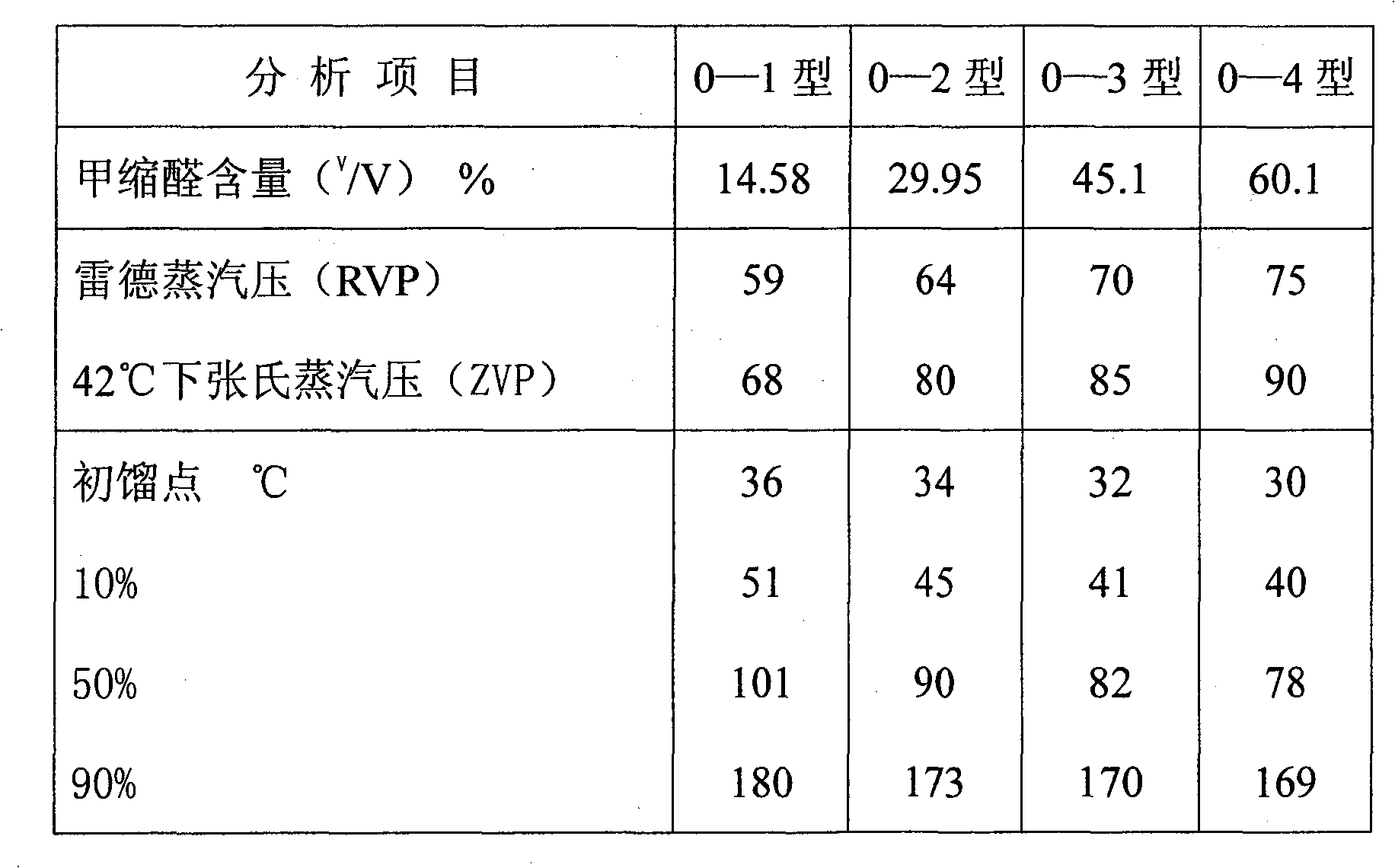

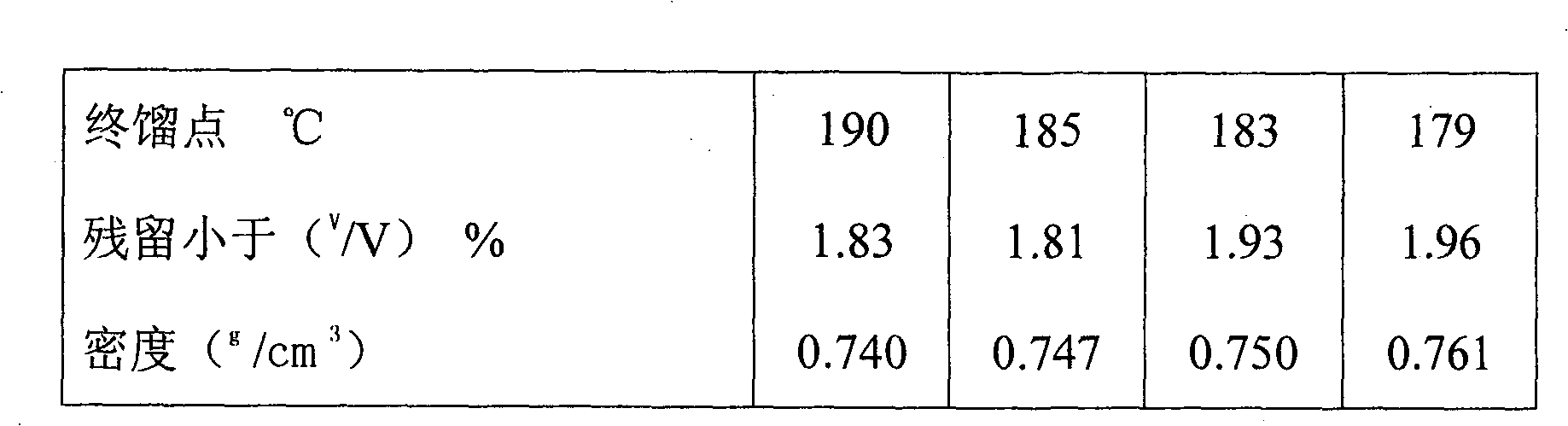

Embodiment 1

[0014] Mix 174kg of crude methylal, 850kg of component oil, and 0.5kg of anti-corrosion swelling agent. Crude methylal contains 1.8% water and 12% methanol in this example. The component oil is a distillate with an initial boiling point of 40°C and a final boiling point of 200°C. The mixture is pumped into a general-purpose liquid-liquid extraction tower at normal temperature and pressure, and 20kg of dehydrating agent is sprayed at the same time. Gasoline, crude methylal, and dehydrating agent passing through ten trays in the flow from top to bottom are mixed several times, and after mass transfer, impurities methanol and water dissolve into the dehydrating agent. The lower layer is the dehydrating agent and impurities. The dehydrating agent and impurities are pumped into the dehydrating agent regeneration tank. After being heated in the regeneration tank, the methanol and water are steamed and condensed, and then returned to the methylal plant for recycling; the upper layer ...

Embodiment 2

[0016] Mix 361kg of crude methylal, 700kg of component oil, and 0.7kg of anti-corrosion swelling agent. Crude methylal contains 1.8% water and 15% methanol in this example. The component oil is a distillate with an initial boiling point of 60°C and a final boiling point of 200°C. The mixture is pumped into a general-purpose liquid-liquid extraction tower at normal temperature and pressure, and 40kg of dehydrating agent is sprayed into it at the same time. Gasoline, crude methylal, and dehydrating agent passing through ten trays in the flow from top to bottom are mixed several times, and after mass transfer, impurities methanol and water dissolve into the dehydrating agent. The lower layer is the dehydrating agent and impurities. The dehydrating agent and impurities are pumped into the dehydrating agent regeneration tank. After being heated in the regeneration tank, the methanol and water are steamed and condensed, and then returned to the methylal plant for recycling; the uppe...

Embodiment 3

[0018] 511kg of crude methylal, 550kg of component oil, and 0.9kg of anti-corrosion swelling agent were mixed. Crude methylal contains 1.5% water and 10.5% methanol in this example. The component oil is a distillate with an initial boiling point of 70°C and a final boiling point of 200°C. The mixture is pumped into a general-purpose liquid-liquid extraction tower at normal temperature and pressure, and 40kg of dehydrating agent is sprayed into it at the same time. Gasoline, crude methylal, and dehydrating agent passing through ten trays in the flow from top to bottom are mixed several times, and after mass transfer, impurities methanol and water dissolve into the dehydrating agent. The lower layer is the dehydrating agent and impurities. The dehydrating agent and impurities are pumped into the dehydrating agent regeneration tank. After being heated in the regeneration tank, the methanol and water are steamed and condensed, and then returned to the methylal plant for recycling;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com