Continuous production process for preparing succinyl oxide by maleic anhydride hydrogenation

A production process and a technology for producing succinic anhydride, which is applied in the field of continuous production technology for hydrogenating maleic anhydride to produce succinic anhydride, can solve the problems of complicated operation steps, short catalyst life, difficult separation of products and catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

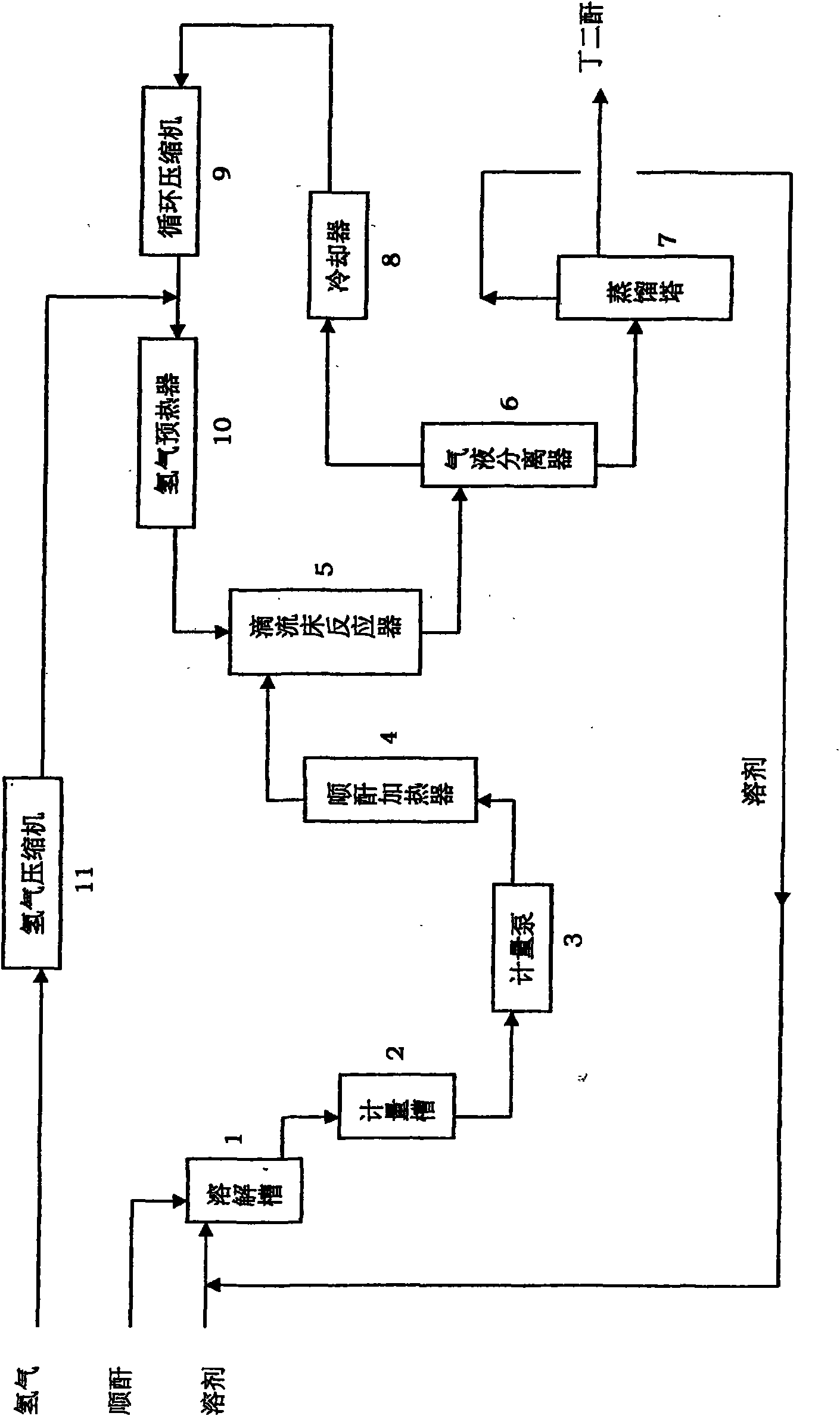

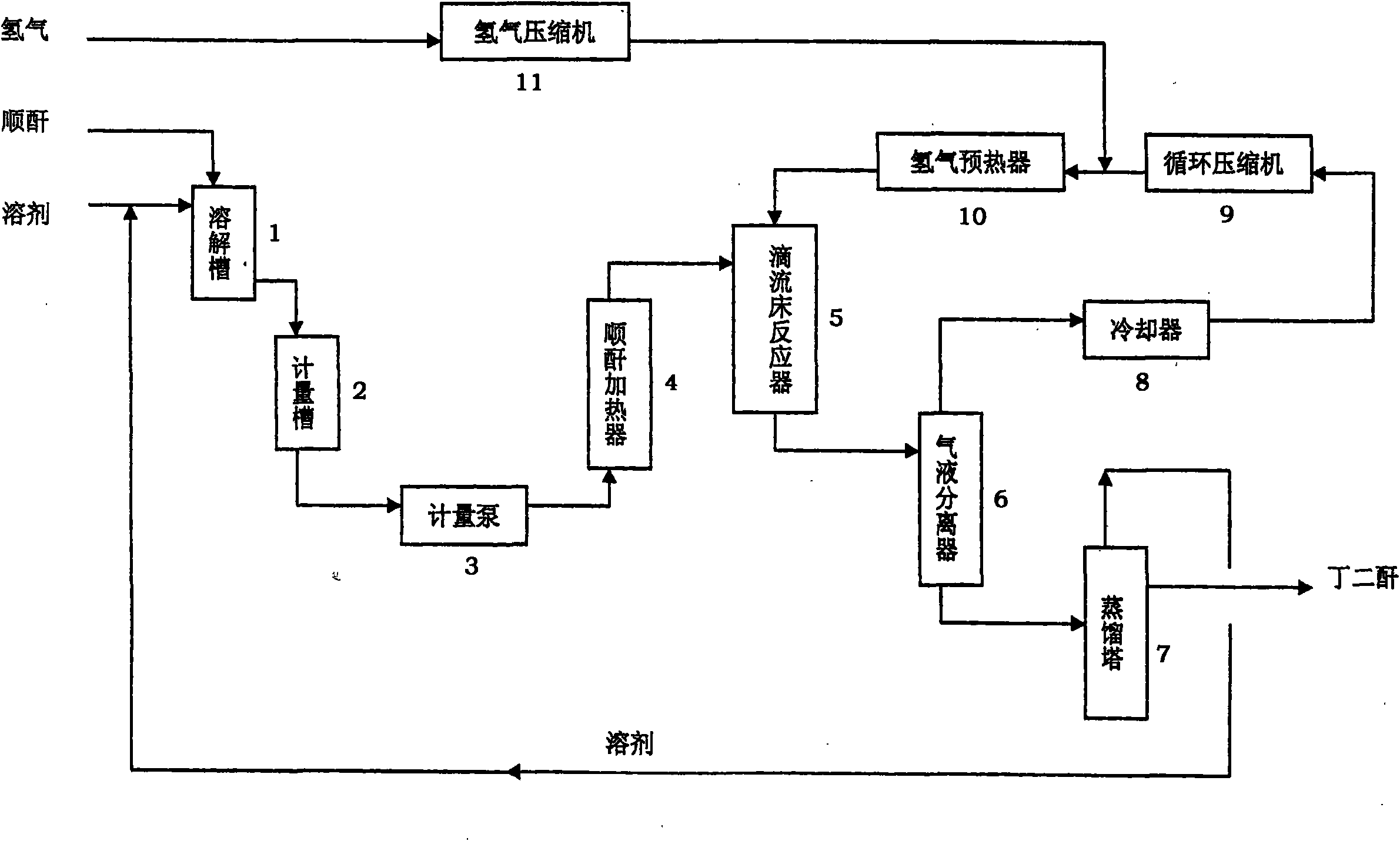

Embodiment 1

[0021] A production plant with an annual output of 10,000 tons of succinic anhydride, with 3.75 tons of the aforementioned Ni / Al in the trickle bed reactor 5 2 o 3 -SiO 2 Catalyst (made into strips with a diameter of 2mm and a length of 8-12mm), after being reduced with nitrogen and hydrogen containing about 1% hydrogen, the system is replaced with hydrogen, the pressure is increased to 8.0Mpa, and the circulating compressor is started for hydrogen circulation; at the same time, press the solvent The weight ratio with maleic anhydride is 4.9: 1 proportioning, maleic anhydride is added in the dissolving tank 1 that fills gamma-butyrolactone (used as a solvent), and after it dissolves, it can be transferred to metering tank 2; When the catalyst bed temperature of the reactor drops to 40-50°C, the metering pump 3 can be started to feed the reactor; at this time, the molar ratio of hydrogen and maleic anhydride entering the reactor must be adjusted synchronously according to the ...

Embodiment 2

[0023] When using granular Ni / Al 2 o 3 Catalyst, and no solvent is used, the dissolution tank becomes a melting tank (maintained at 53-60 ° C), the maleic anhydride is melted here, and after melting, it is fed into the metering tank, and the maleic anhydride is fed separately (that is, the weight ratio of solvent to maleic anhydride is 0:1 ); This time, the molar ratio of hydrogen and maleic anhydride that needs to be adjusted into the trickle bed reactor 5 is 92: 1 in addition, and the preheating temperature before the trickle bed reactor 5 should be controlled at 53-55 ℃, and the reactant is Liquid separator 6, the separated liquid phase product (crude product succinic anhydride) goes to distillation tower 7, obtains the succinic anhydride product with purity greater than 99.5% through distillation, and the separated hydrogen enters 9 pressurizations of circulating compressor after cooling, and the rest Operation steps and index are the same as embodiment 1, can obtain same...

Embodiment 3

[0025] When using granular aforementioned Raney nickel catalyst instead, dioxane is solvent, and the weight ratio of solvent and maleic anhydride is 15: 1, and the mol ratio of the hydrogen that enters trickle-bed reactor 5 and maleic anhydride is 1.1: 1, All the other operation steps and index are the same as embodiment 1, also can obtain same effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com