Large-size optical fiber preform and manufacturing method of optical fiber thereof

An optical fiber preform and manufacturing method technology, applied in the directions of clad optical fibers, glass optical fibers, manufacturing tools, etc., can solve the problems affecting the low water peak performance and bending resistance performance of optical fibers, many socket interfaces, and many processing links, etc., Achieve the effect of ensuring low water peak performance, ensuring low attenuation performance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The optical fiber core rod is prepared by the PCVD process. The liner used is a fluorine-doped liner, which is prepared by the OVD process. The fluorine-doped liner is cleaned and fully dried before deposition, and the deposited fluorine-doped tube is melted and shrunk in an electric heating furnace After being corroded, cleaned and dried, the core rod is assembled into a RIC process preform with a high-purity quartz tube. The main parameters of the preform are shown in Table 1; the RIC preform is directly drawn, and the two-layer Optical fiber coating material, the drawing speed is 1500m / min, the fiber diameter is 125±0.7μm, and the pressure inside the RIC is controlled to be 1,000pa~10,000pa. The main performance parameters of the drawn fiber are shown in Table 2.

[0076] Table 1. Basic parameters of the preform rod of embodiment 1

[0077]

[0078] Table 2. Main properties of the drawn optical fiber of embodiment 1

[0079]

[0080] In Example 1, the CSA of ...

Embodiment 2

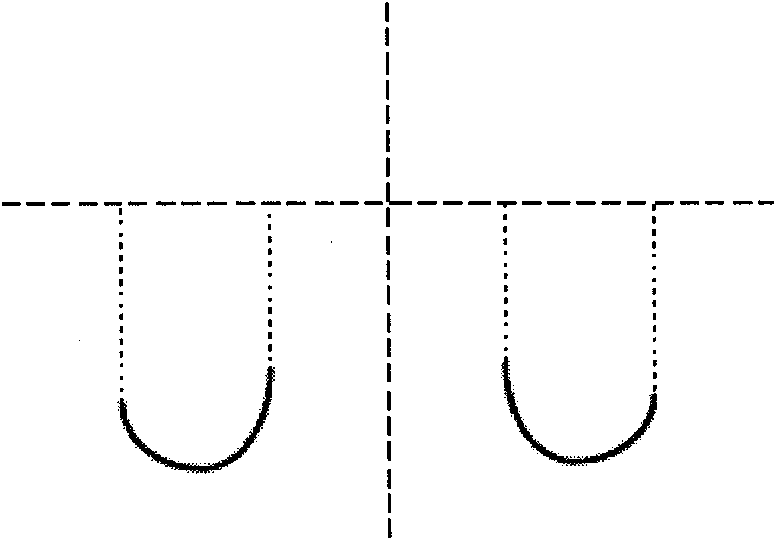

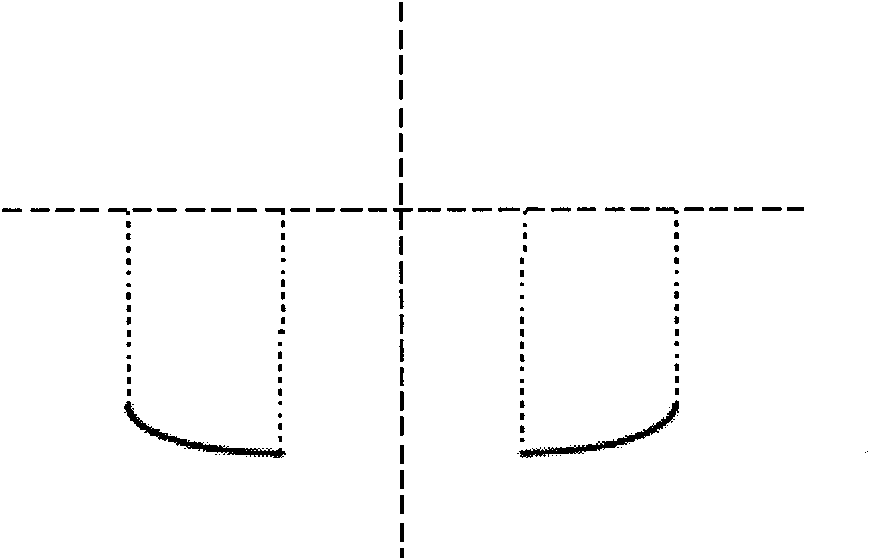

[0084] In the OVD or VAD manufacturing outer cladding deposition process, due to the use of H2 / O2 flame, the hydroxyl pollution of the core rod is obvious; when the APVD process is used, not only the hydroxyl content in the deposited glass is high, but also in the environment The hydroxyl groups in the target rod will also be adsorbed on the target rod and diffuse inward; once the hydroxyl group diffuses into the core layer of the core rod, it will cause an increase in the water peak of the optical fiber. Whether the hydroxyl group can diffuse inward into the core layer of the core rod mainly depends on the diffusion distance and diffusion coefficient. The way to increase the diffusion distance is to increase the c / a value of the mandrel. The core rods with different c / a values are manufactured by the same method as in Example 1, and the OVD and APVD processes are used to manufacture the outer cladding, and the outer diameter is 145-155mm. ±0.7μm, the relationship between t...

Embodiment 3

[0086] The optical fiber core rod is prepared by the PCVD process. The liner used is a fluorine-doped liner, which is prepared by the OVD process. The fluorine-doped liner is cleaned and fully dried before deposition, and the deposited fluorine-doped tube is melted and shrunk in an electric heating furnace into a solid mandrel, and the mandrel is corroded, cleaned and dried and assembled into a RIC process preform by RIC process and high-purity quartz tube. The main parameters of the preform are shown in Table 3; Optical fiber coating material, the drawing speed is 1500m / min, the fiber diameter is 125±0.7μm, and the pressure inside the RIC is controlled to be 1,000pa~10,000pa. The main performance parameters of the drawn fiber are shown in Table 4.

[0087] In embodiment 3, the CSA of the used fluorine-doped liner is less than the area of the ring where the sunken cladding in the designed core rod is, so it is necessary to deposit part of the fluorine-doped sunken cladding b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com