Preparation method of hollow circular-tube tetrahedral full-composite lattice sandwich board

A composite material and sandwich panel technology, which is applied in the field of preparation of hollow circular tube tetrahedron type full composite lattice sandwich panels, can solve the problem of not being applicable to the preparation of composite lattice sandwich panels, and achieves improved structural strength, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

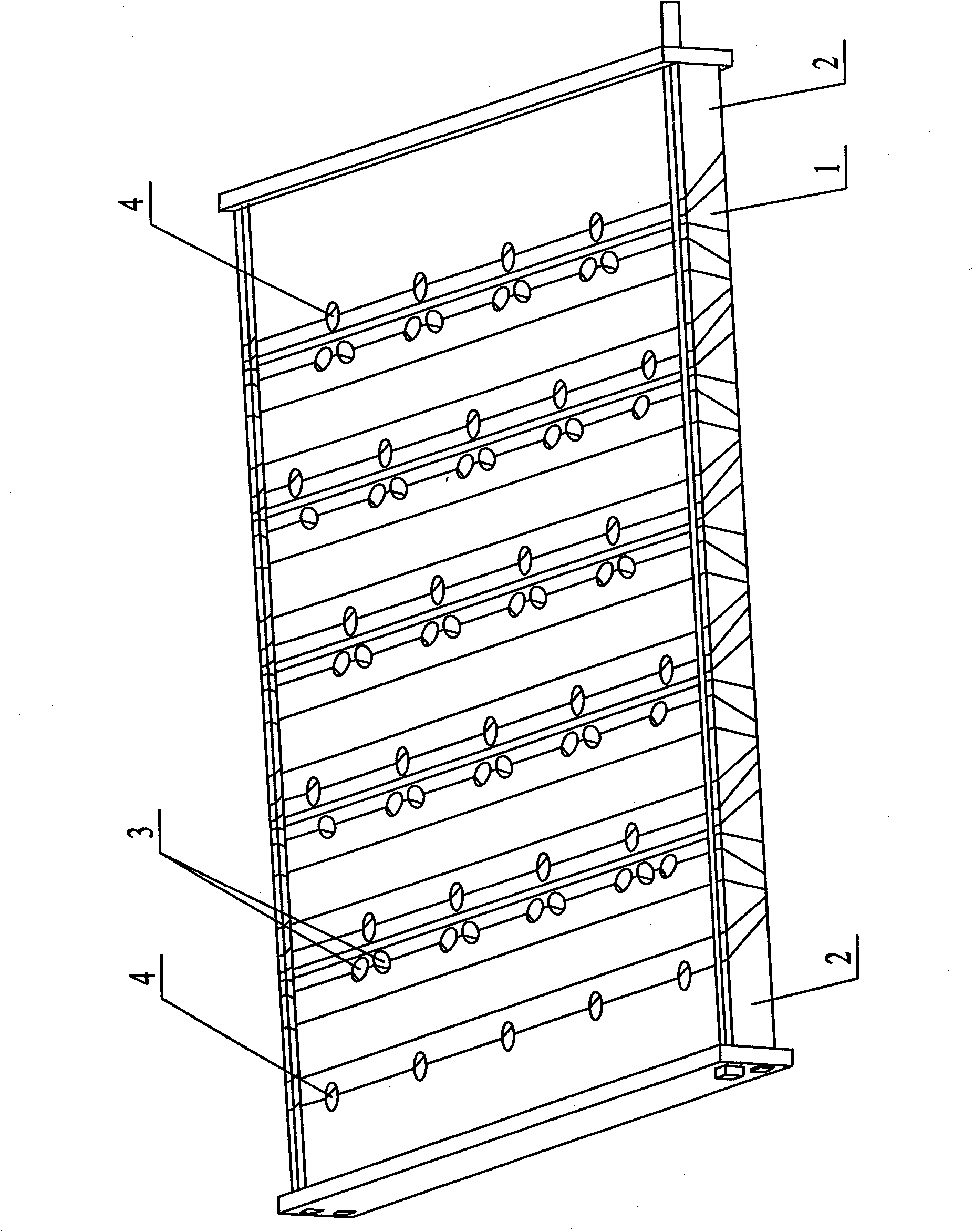

[0016] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, the steps of the preparation method of the hollow tube tetrahedral full-composite lattice sandwich panel of this embodiment are as follows:

[0017] Step 1: Rigid mold preparation and mold processing:

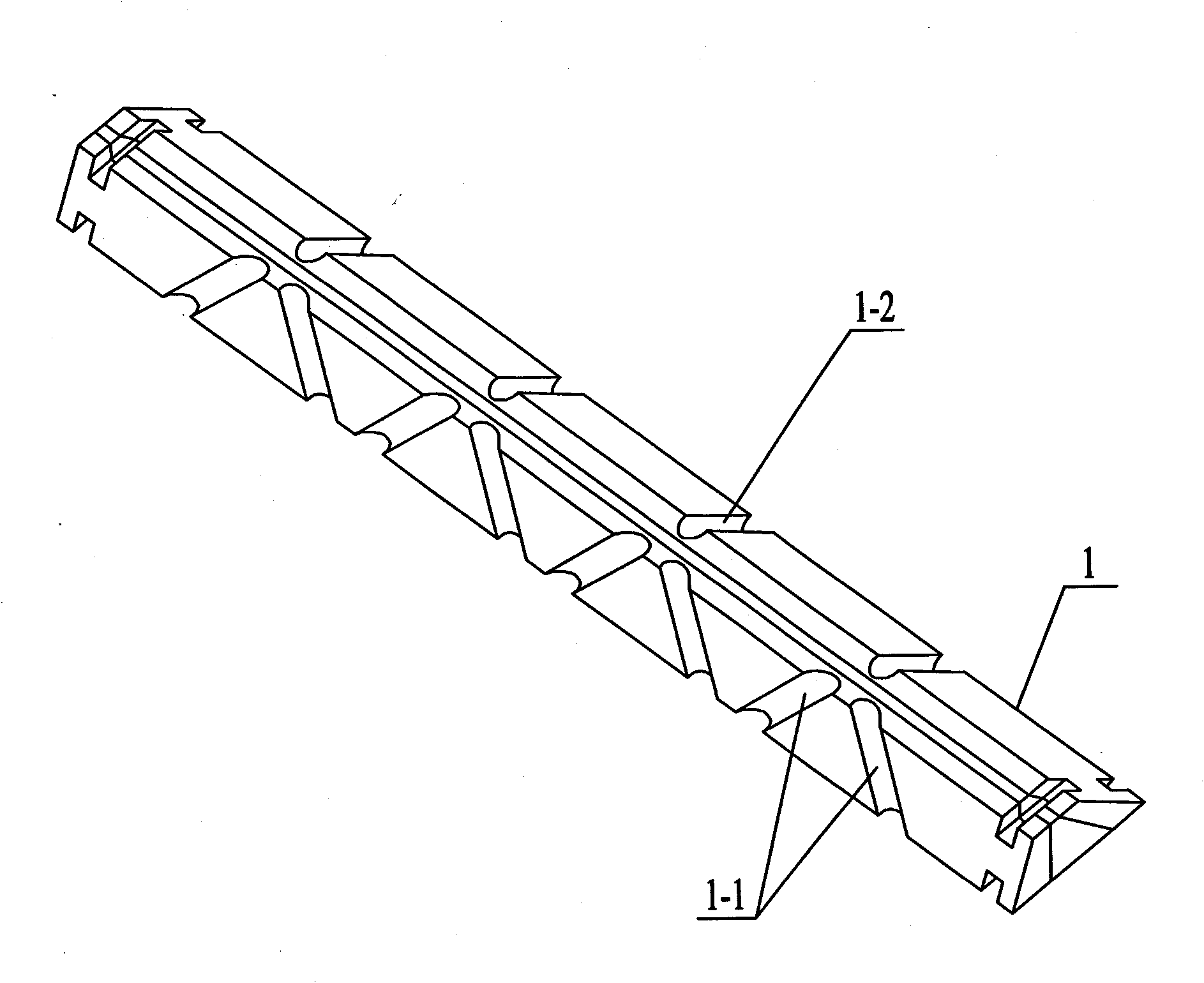

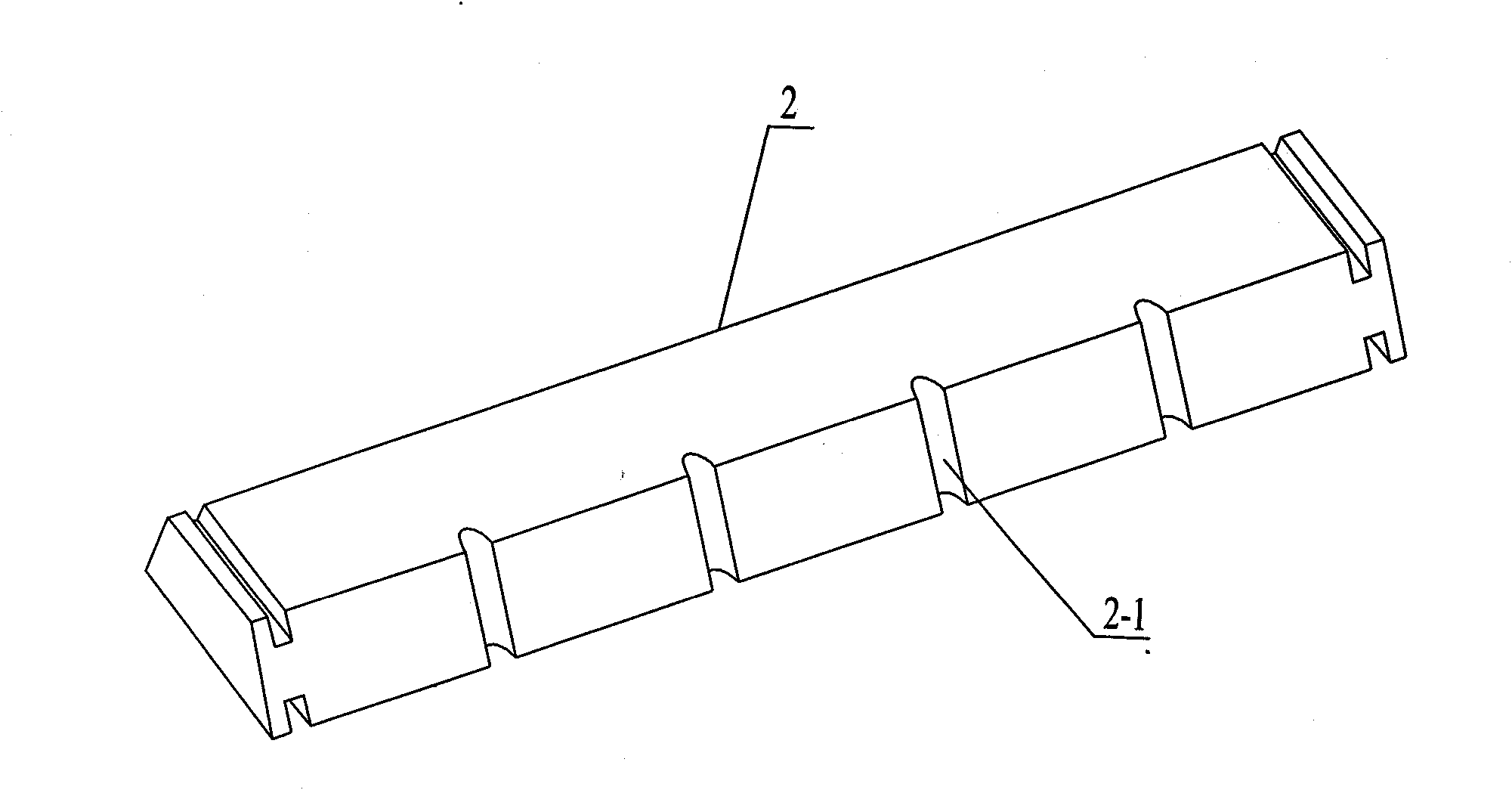

[0018] Rigid mold preparation: The rigid mold is composed of multiple monomers 1 and two side plates 2, the cross-sectional shape of each monomer 1 is trapezoidal, and the cross-sectional shape of each side plate 2 is a right-angled trapezoid; A plurality of pairs of first semicircular through-holes 1-1 penetrating along the width direction of the inclined-plane are processed on one slope of 1, and each pair of first semicircular through-holes 1-1 is arranged in a figure-eight shape, and in each monomer 1 On the other slope, a second semicircular through hole 1-2 penetrating along the width direction of the slope is processed on the middle position of each pair of first semicircu...

specific Embodiment approach 2

[0027] Embodiment 2: The heat-expandable mandrel 5 in step 1 of this embodiment is made of polymethacrylimide foam. The heat-expandable mandrel 5 remains in the sandwich structure with round holes in the panel, and such a structure has improved impact resistance and excellent dielectric properties. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The heat-expandable mandrel 5 in step 1 of this embodiment is made of silicone rubber, and in step 6, the heat-expandable mandrel 5 is extruded after demolding the rigid composite mold. Other method steps are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com