Cleaner for inner wall of steel pipe

A technology for cleaning device and inner wall of steel pipe, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of limited spray force of nozzles, damage, leakage of cleaning liquid, etc. Production cost and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

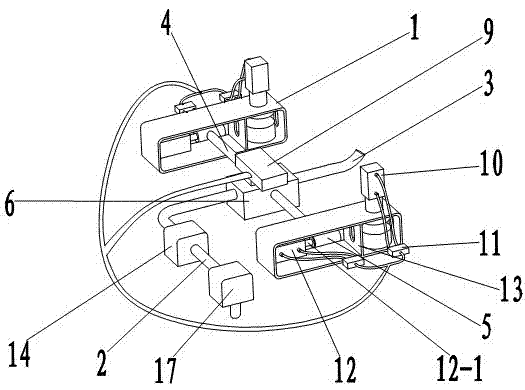

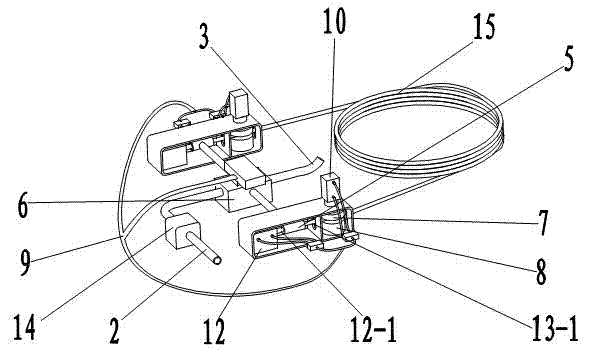

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Referring to the accompanying drawings: this steel pipe inner wall cleaning device in this embodiment includes a water pump 17, a four-way reversing valve 6, and the four-way reversing valve 6 is provided with a water inlet pipe 2, a drain pipe 3 and two left and right connecting pipes 4 , the ends of the two connecting pipes 4 are respectively connected to the casing 5, the casing 5 has a cavity 5-1 communicating with the connecting pipe 4, and the front end of the casing 5 forms a socket hole matching the end of the steel pipe 15 5-2, the cavity 5-1 communicates with the socket hole 5-2. The steel pipe inner wall cleaning device also has three abrasive cloth groups 16 placed in the steel pipe 15, and the inner end of the socket hole 5-2 is provided with a limiter 5-3, and the limiter 5-3 is located in the casing 5 The radial height is greater than the wall thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com