Energy recovery braking system for automobile suspension

A braking system and automobile suspension technology, applied in the direction of suspension, brakes, elastic suspension, etc., can solve the problems of reducing energy utilization efficiency, increasing the cost of energy conversion devices, restricting system design and structural layout, and achieving attenuation Vibration energy, the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

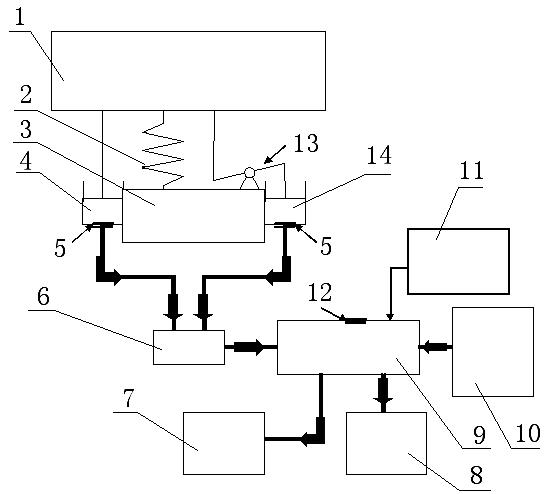

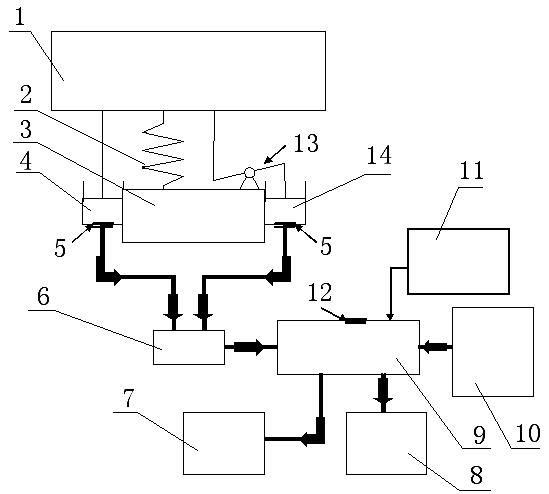

[0023] refer to figure 1 , the automobile suspension energy-feeding braking system of the present embodiment is arranged between the automobile suspension and the pneumatic braking system, and it includes an accumulator 6, an energy-feeding cylinder 4, an energy-feeding cylinder Ⅱ 14 、 The energy feed control module 11, one end of the energy feed cylinder 4 is connected to the suspension 1, the other end is connected to the accumulator 6, and the other end of the accumulator 6 is connected to the air storage tank 9 of the air pressure braking system. The cylinder body of the energy feeding cylinder 4 is fixedly arranged on the axle 3 , the piston rod end is arranged on the automobile suspension 1 , and a check valve 5 is arranged between the energy feeding cylinder 4 and the accumulator 6 . The energy feeding control module 11 is connected with the air storage tank 9 . The feed cylinder Ⅱ The cylinder body of 14 is fixedly arranged on the axle 3, and the piston rod end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com