Device for Improving Filtration Speed of Cutting Fluid

A technology of filtration speed and filtration device, applied in filtration separation, membrane filter, fixed filter element filter, etc., can solve problems such as accelerated filtration, and achieve the effect of accelerating filtration speed, improving filtration speed and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

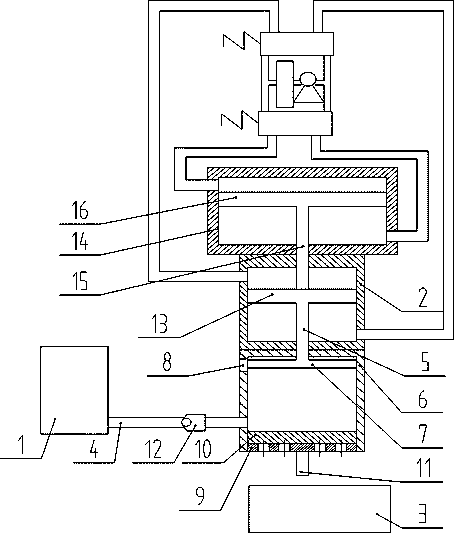

[0021] Such as figure 1 As shown, the device for improving the filtration speed of cutting fluid in the present invention includes a storage tank 1, a first-stage hydraulic cylinder 2, a pressurized hydraulic cylinder 14, a filter device, a liquid storage tank 3 and a pipeline 4; the storage tank 1 is used to store For cutting fluid, the pipeline 4 communicates the storage tank 1 with the filter device; the cutting fluid enters the filter device through the pipeline 4 . The liquid storage tank 3 is located below the filter device, and the liquid storage tank 3 is used to store the liquid filtered by the filter device; the filter device includes a filter assembly and a filter cylinder 6 with a bottom opening, and the filter assembly is arranged on the filter cylinder 6 The bottom; the first stage hydraulic cylinder 2 includes a cylinder body, the first stage piston rod 5 and the piston I13; the booster hydraulic cylinder 14 includes a cylinder body, a booster piston rod 15 and ...

Embodiment 2

[0027] The structure of this embodiment is the same as that of Embodiment 1, and this embodiment is an instruction for the use of Embodiment 1.

[0028] Use the steps of the present invention as follows:

[0029] 1. Supply oil to the lower chamber of the first-stage hydraulic cylinder 2, the piston Ⅰ13 in the first-stage hydraulic cylinder 2 moves upward under the push of oil pressure, and drives the piston Ⅱ7 connected to the first-stage piston rod 5 to move upward , the volume of the inner cavity at the lower end of the piston II7 increases to form a local cavity; at this time, the one-way valve 12 is opened, and the cutting fluid is sucked from the storage tank through the pipeline 4;

[0030] 2. Supply oil to the upper chamber of the first-stage hydraulic cylinder 2, the piston I13 in the first-stage hydraulic cylinder 2 moves downward under the push of oil pressure, and drives the piston II7 connected to the first-stage piston rod 5 to Moving down, the volume of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com