Preparation method of carbon supported cobalt phthalocyanine catalytic material

A carbon-supported cobalt phthalocyanine catalytic material and catalytic material technology, applied in the field of electrochemistry, can solve the problems of difficult to achieve large output working voltage, low catalytic activity of the product, complicated preparation process, etc., to achieve enhanced oxygen reduction activity and stable Sexuality, low price, wide range of raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Put Cabot's VulcanXC-72 product at a concentration of 6mol L -1 Hydrochloric acid solution to remove possible chloride impurities, filter to remove the solution and wash with a large amount of distilled water. Then immerse and oxidize with a nitric acid solution with a concentration of 65%, filter to remove the solution, wash with a large amount of distilled water, dry at 80°C, and grind to obtain pretreated VulcanXC-72 for use.

[0037] (2) VulcanXC-72 2.2g, phthalic anhydride 2.98g, urea 4.8g, CoCl 2 ·6H 2 O0.98g (to make the metal content 8wt%), ammonium molybdate 0.05g mixed, after that, put it in a mortar and grind it fully, then put it in a muffle furnace to raise the temperature to 900 ° C, keep the temperature for 3 hours, and obtain carbon-supported cobalt phthalocyanine Composite catalytic material CoPc / C.

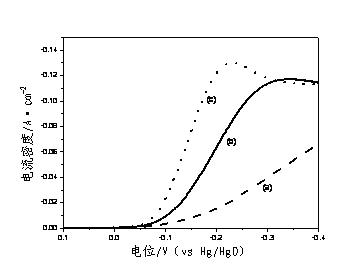

[0038] The obtained catalytic material is made into an air electrode according to the traditional method, and its effective area is 1 cm 2 , to 4c...

Embodiment 2

[0041] (1) Put Cabot's VulcanXC-72 product into 30% H 2 o 2 Soak in water for 24 hours, remove the solution by filtration, wash with a large amount of deionized water, dry at 80°C, and grind to obtain pretreated VulcanXC-72.

[0042] (2) VulcanXC-72 2.2g, phthalic anhydride 2.98g, urea 4.8g, CoCl 2 ·6H 2 O0.98g (to make the metal content 8wt%), ammonium molybdate 0.05g mixed, after that, put it in a mortar and grind it fully, then put it in a muffle furnace to raise the temperature to 900 ° C, keep the temperature for 3 hours, and obtain carbon-supported cobalt phthalocyanine Composite catalytic material CoPc / C.

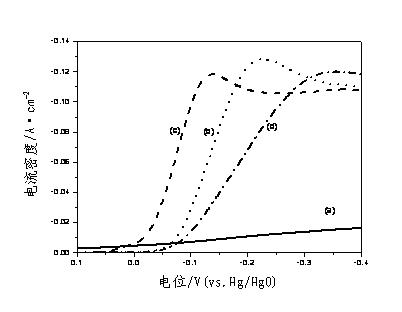

[0043] The obtained catalytic material is made into an air electrode according to the traditional method, and its effective area is 1 cm 2 , to 4cm 2 The platinum sheet was used as the counter electrode, and the Hg / HgO electrode was used as the reference electrode.

[0044] In the air atmosphere, 6mol / LKOH electrolyte, the polarization curve of the electrode of...

Embodiment 3

[0046] (1) Put Cabot's VulcanXC-72 product into 30% H 2 o 2 Soak in water for 24 hours, remove the solution by filtration, wash with a large amount of deionized water, dry at 80°C, and grind to obtain pretreated VulcanXC-72.

[0047] (2) VulcanXC-72 2.2g, CoCl 2 ·6H 2 O 0.30g (to make the metal content 2.5wt%), phthalic anhydride 2.98g, urea 4.8g, ammonium molybdate 0.05g mixed, after that, put it in a mortar and grind it thoroughly before putting it in a muffle furnace to raise the temperature To 900 ℃, constant temperature 3h, prepared carbon-supported cobalt phthalocyanine composite catalytic material CoPc / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com