Four-folding beam variable area differential capacitance structure micro-acceleration sensor and manufacture method thereof

A technology of acceleration sensor and differential capacitance, applied in the field of micro-acceleration sensor and its preparation, can solve the problems of small variation of differential capacitance, difficult processing circuit, etc., and achieve the effects of increasing sensitivity, improving anti-interference ability, and solving nonlinear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

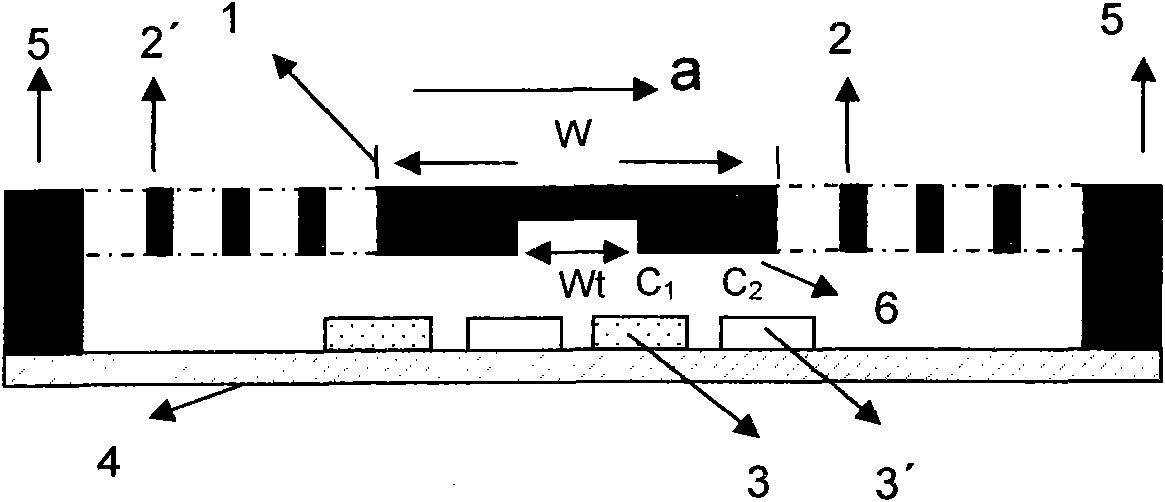

[0028] The structural parameters of the micro-acceleration sensor of the present invention are shown in Table 1. 20 upper electrode arrays are made on the lower surface of the movable mass, and the corresponding finger-shaped lower electrodes adopt 20 pairs of electrode structures, thereby forming 20 identical capacitors in parallel.

[0029] Table 1: Parameters of mass and folded beam

[0030]

[0031]

[0032] After the structural size design of the device is completed, the following method can be used to fabricate the device.

[0033] A: Fabrication of the lower electrode

[0034] 1) Use Pyrex7740 with a thickness of 200 microns # borosilicate glass;

[0035] 2) Form a photoresist pattern complementary to the lower electrode structure to be made on the glass through a photolithography process, and then sputter a 50nm gold layer on the photoresist as the lower electrode material;

[0036] 3) The photoresist and the gold layer on it are removed by using the strippi...

Embodiment 2

[0044] The overall scheme of the detection circuit is as follows Figure 5 As shown, the carrier generator provides a stable sine wave for the whole circuit, and the differential capacitance of the acceleration sensor (C 1 、C 2 ) is connected to the input terminal of the charge amplifier, and the charge amplifier circuit (such as Figure 6Shown) converts a small differential capacitance change into a voltage change. Since the differential capacitance change is very small, the voltage change is also very weak. For the convenience of subsequent circuit detection, the signal is amplified by a DC amplifier, but the signal at this time still contains high-frequency noise and other interference, and the high-Q band-pass filter filters out the interference to make the waveform better. The signal at this time and the signal after the phase-shifting circuit are used as the input of the phase-sensitive demodulation circuit. When the two signals are inverting or in-phase at the same fr...

Embodiment 3

[0050] Charge amplification circuit design: such as Figure 6 Shown, C 1 、C 2 are the two differential capacitors of the accelerometer, C 3 is the feedback capacitor of the op amp, C 4 The role is to remove noise interference, R 1 and the feedback capacitor C 3 in parallel.

[0051] After selecting the relevant circuit component parameters, the circuit is analyzed and the equations are obtained:

[0052] V ′ - V o 1 s C 3 / / R 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com