Bell-less top multi-ring matrix burden distribution central coke charging method of blast furnace

A technology of cloth and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of easily smashed coke layer, unstable furnace condition, difficult to ensure the stability of central gas, etc., to reduce production costs and stabilize the edge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment (Germany AMEH factory 5A blast furnace (furnace capacity 2032 stands))

[0020] The 5A blast furnace is equipped with a set of Paul Wurth ring-shaped bellless furnace roof distribution system (the capacity of the receiving hopper is 24m 3 , silo capacity 36m 3 ) (using a water-cooled gearbox and a 3.5m long cloth chute).

[0021] Sintered ore is screened and divided into three particle sizes: >8mm, 4-8mm and <4mm. Sinters of the first two grain sizes are fed into the blast furnace.

[0022] Coke is divided into three particle sizes of >38mm, 10-38mm and <10mm. Cokes of the first two sizes are fed directly into the blast furnace.

[0023] The charge used is sinter, pellet and lump ore (the ratio is about 80% / 90% / 11%). Sintered ore includes small-grained sintered ore. The reducing agent is coke and coal powder.

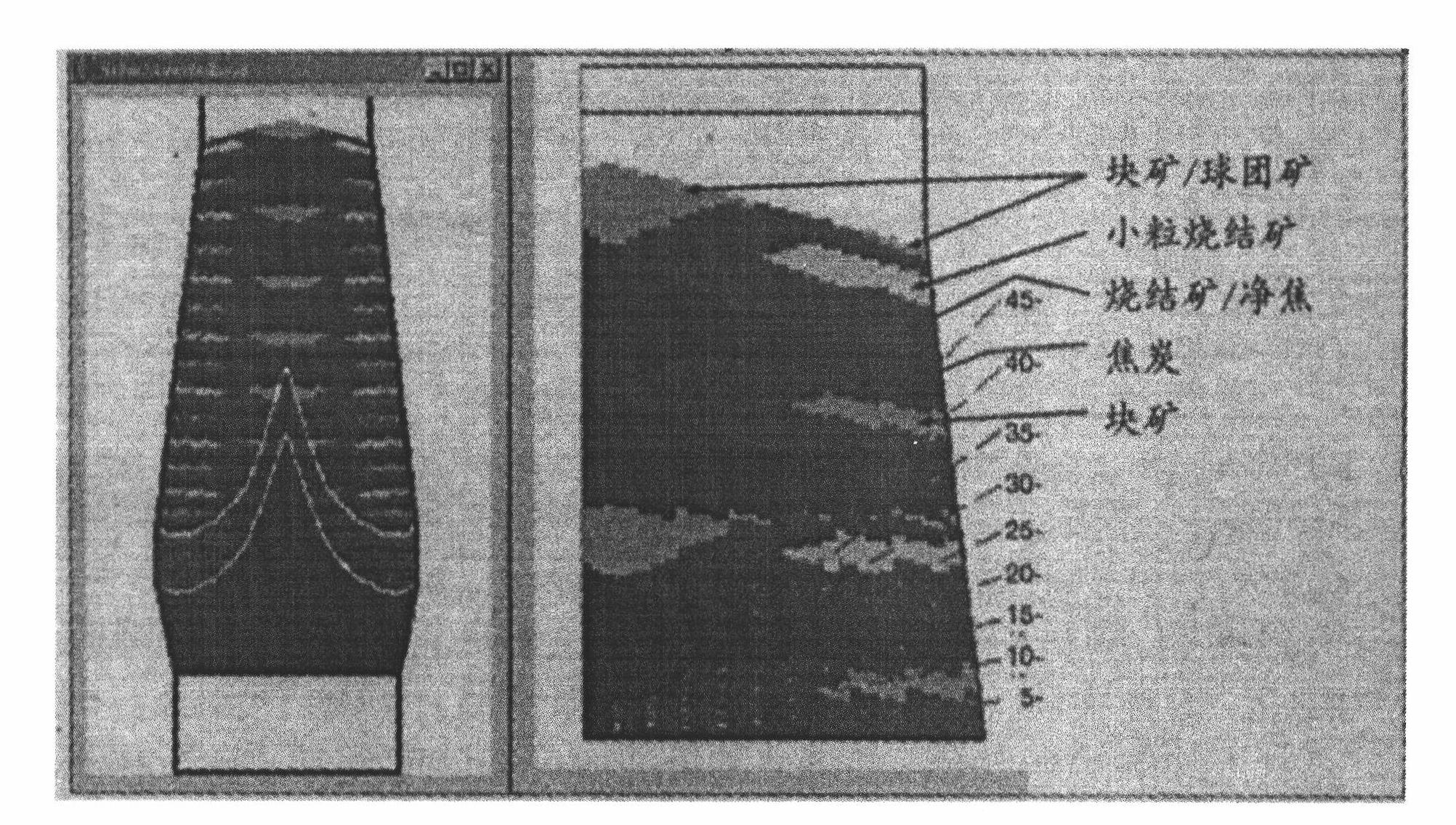

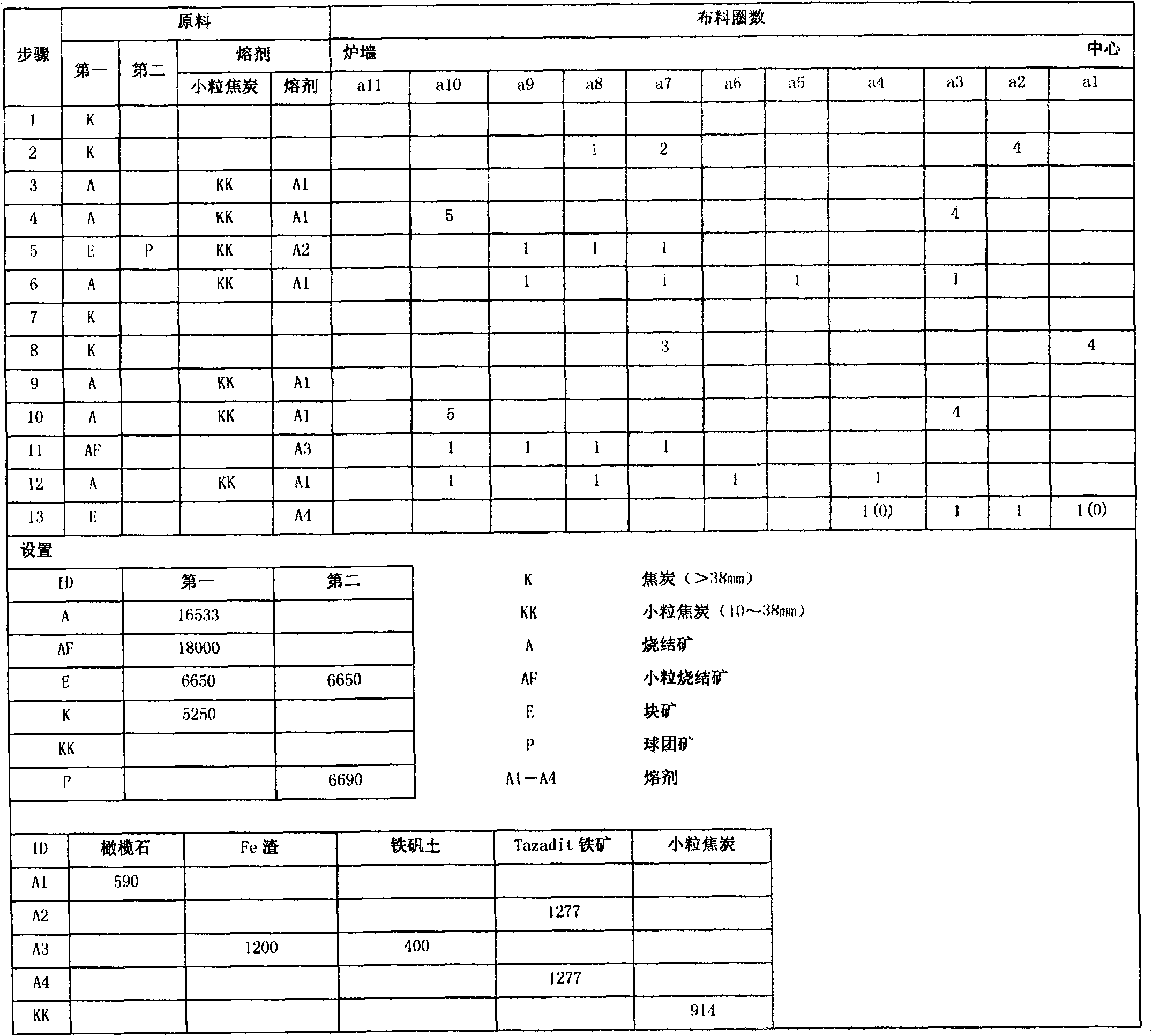

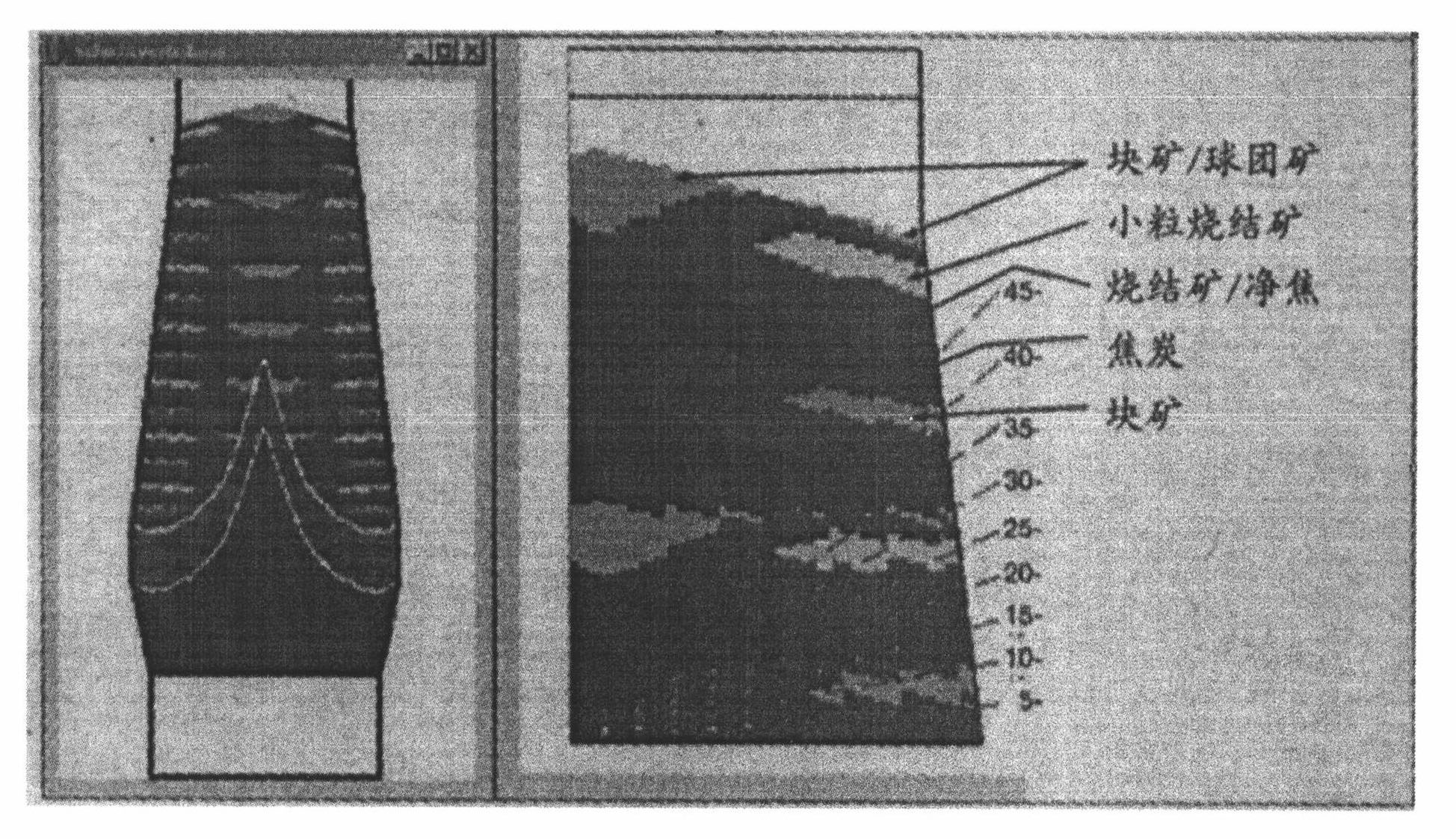

[0024] Table 1 is the standard charging information of 5A blast furnace. figure 1 It is the effect drawing of standard charging of 5A blast fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com