Chemical container for high-pure chemicals storage

A chemical product and chemical technology, applied in the field of chemical containers, can solve the problems of high production cost and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

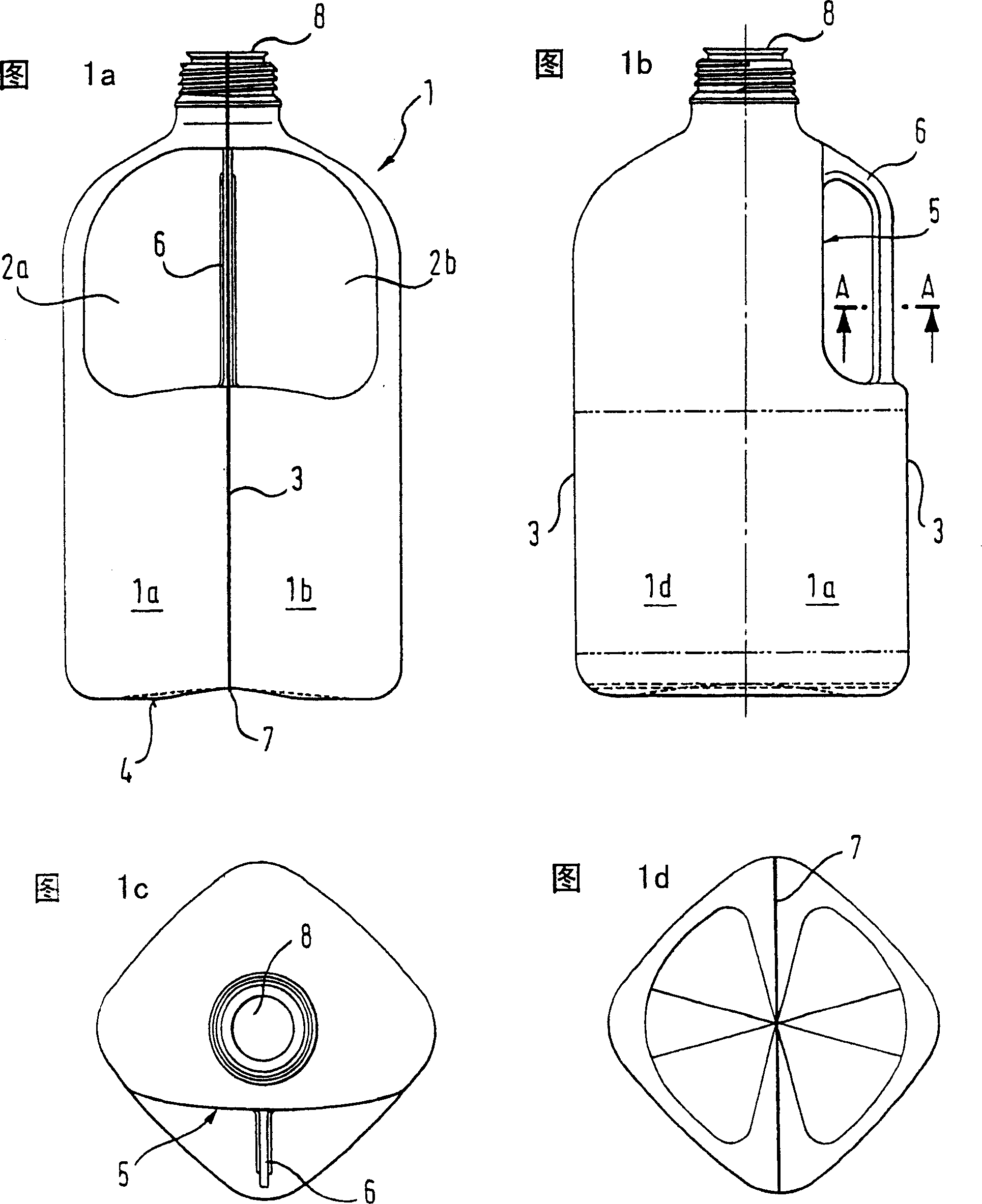

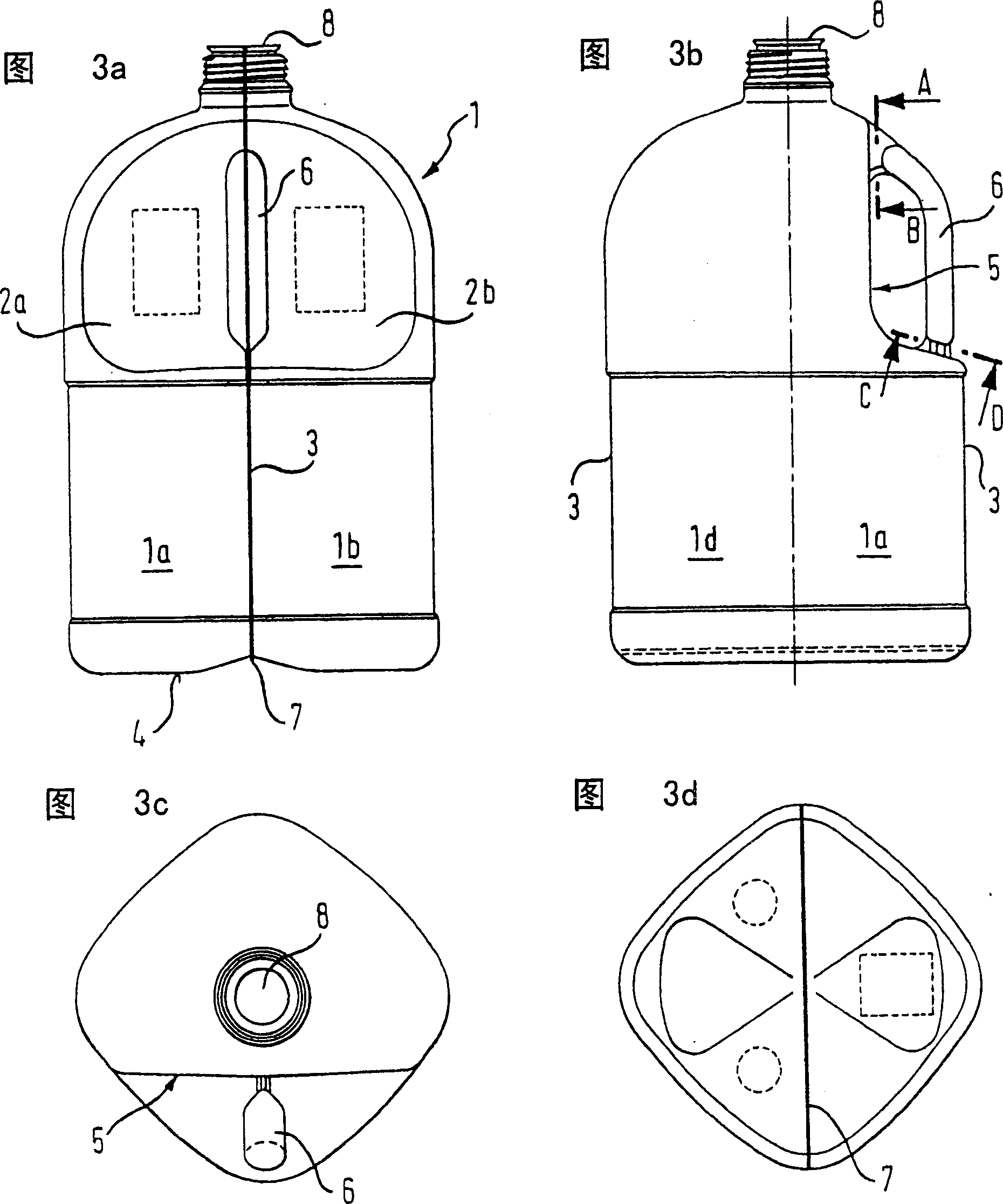

[0024] The chemical container shown in Figures 1a and 1d has a completely symmetrical body 1 in the shape of a bottle consisting of 4 side walls 1a-1d approximately perpendicular to each other and a bottom 4. In the upper part of the container, the side wall forms an opening 8 of the chemical container. Below the opening 8, the container has a threaded cylindrical part. The container is preferably closed with a commercial closure according to utility model G9102564.8.

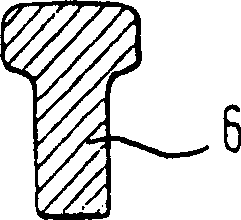

[0025] The two side walls 1a, 1b have partial areas 2a and 2b in their upper part which are inclined towards the rear of the plane of the side walls 1a, 1b and opposite to each other. When the chemical container is in its complete state, the two partial areas 2a, 2b are connected to each other and form an area 5 that is completely perpendicular to the bottom 4 like the side walls 1a-1d. This can be clearly seen in Figure 1b. As shown in Figure 1c, the area 5 is slightly curved, but it is approximately parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com