Method and device for producing synthetic natural gas

A technology for synthesizing natural gas and product gas, which is applied in the production of synthetic natural gas and complete methanation. It can solve the problems of high energy consumption, high operating cost, and low methane concentration, and achieve reasonable process flow, operability, and material requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

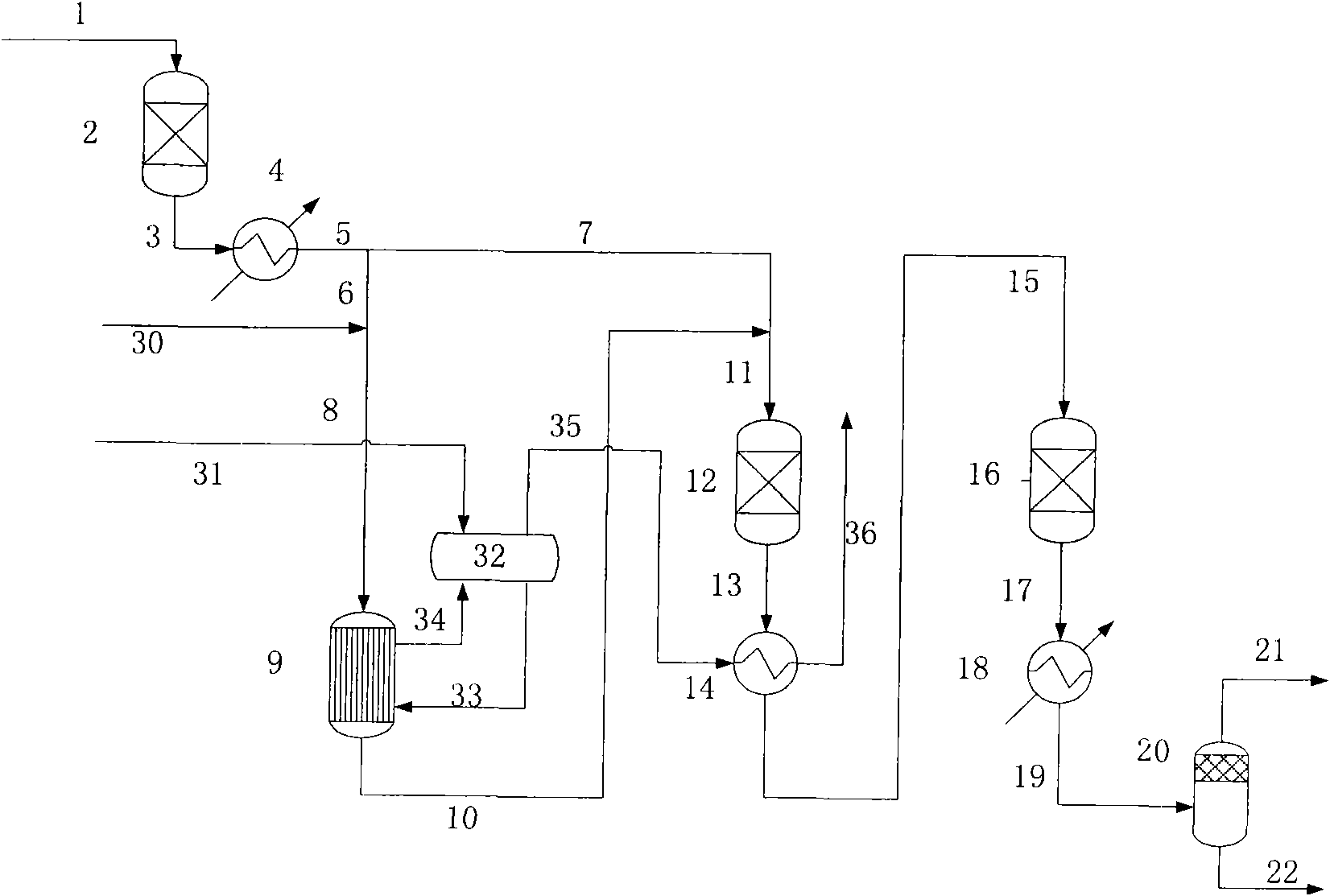

[0053] figure 1 Shown is a preferred embodiment of the production method of synthetic natural gas provided by the present invention.

[0054] The main raw material synthesis gas is produced by the gasifier, and through conventional steps such as quenching, impurities such as tar, phenol, ammonia and dust are removed, and the sulfide and some carbon dioxide contained in it are removed by the acid gas removal unit. The raw material gas 1 passing through the acid gas removal unit enters the purification reactor 2 to further remove trace impurities such as sulfur and oxygen contained therein. The purified raw material gas 3 is preheated by the heat exchanger 4 and divided into two streams, that is, the first raw material gas 6 and the second raw material gas 7 . The first raw material gas 6 is mixed with steam 30, and the temperature of the obtained mixed gas 8 is 250-350°C, which is passed into the first-stage cooling type tubular reactor 9 filled with a methanation catalyst to ...

Embodiment approach 2

[0059] figure 2 Shown is another preferred implementation of the method for producing synthetic natural gas provided by the present invention.

[0060] The main raw material synthesis gas is produced by the gasifier, and through conventional steps such as quenching, impurities such as tar, phenol, ammonia and dust are removed, and the sulfide and some carbon dioxide contained in it are removed by the acid gas removal unit. The raw material gas 1 passing through the acid gas removal unit enters the purification reactor 2 to further remove trace impurities such as sulfur and oxygen contained therein. The purified raw material gas 3 is preheated by the heat exchanger 4 and divided into two streams, that is, the first raw material gas 6 and the second raw material gas 7 . The first raw material gas 6 is mixed with steam 30, and the temperature of the obtained mixed gas 8 is 250-350°C, which is passed into the first-stage cooling type tubular reactor 9 filled with a methanation c...

Embodiment approach 3

[0064] For comparison with Embodiment 1 and Embodiment 2, under the same basic design conditions, the traditional methanation process is used to produce synthetic natural gas. The specific process flow chart is as image 3 shown.

[0065]The main raw material synthesis gas is produced by the gasifier, and through conventional steps such as quenching, impurities such as tar, phenol, ammonia and dust are removed, and the sulfide and some carbon dioxide contained in it are removed by the acid gas removal unit. The raw material gas 1 passing through the acid gas removal unit enters the purification reactor 2 to further remove trace impurities such as sulfur and oxygen contained therein. The purified raw material gas 3 is preheated by the heat exchanger 4 and divided into two streams, that is, the first raw material gas 6 and the second raw material gas 7 . The first raw material gas 6 is mixed with the recycle gas 27', and the temperature of the obtained mixed gas 8' is 250-350°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com