Cooling water temperature self-control circulating system for emulsion explosive production line

A technology for cooling water temperature and emulsification explosives, which is applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as explosion, water temperature cannot meet the process requirements, and can not meet the process requirements of water intake, so as to reduce production costs and save money. Electricity resources and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

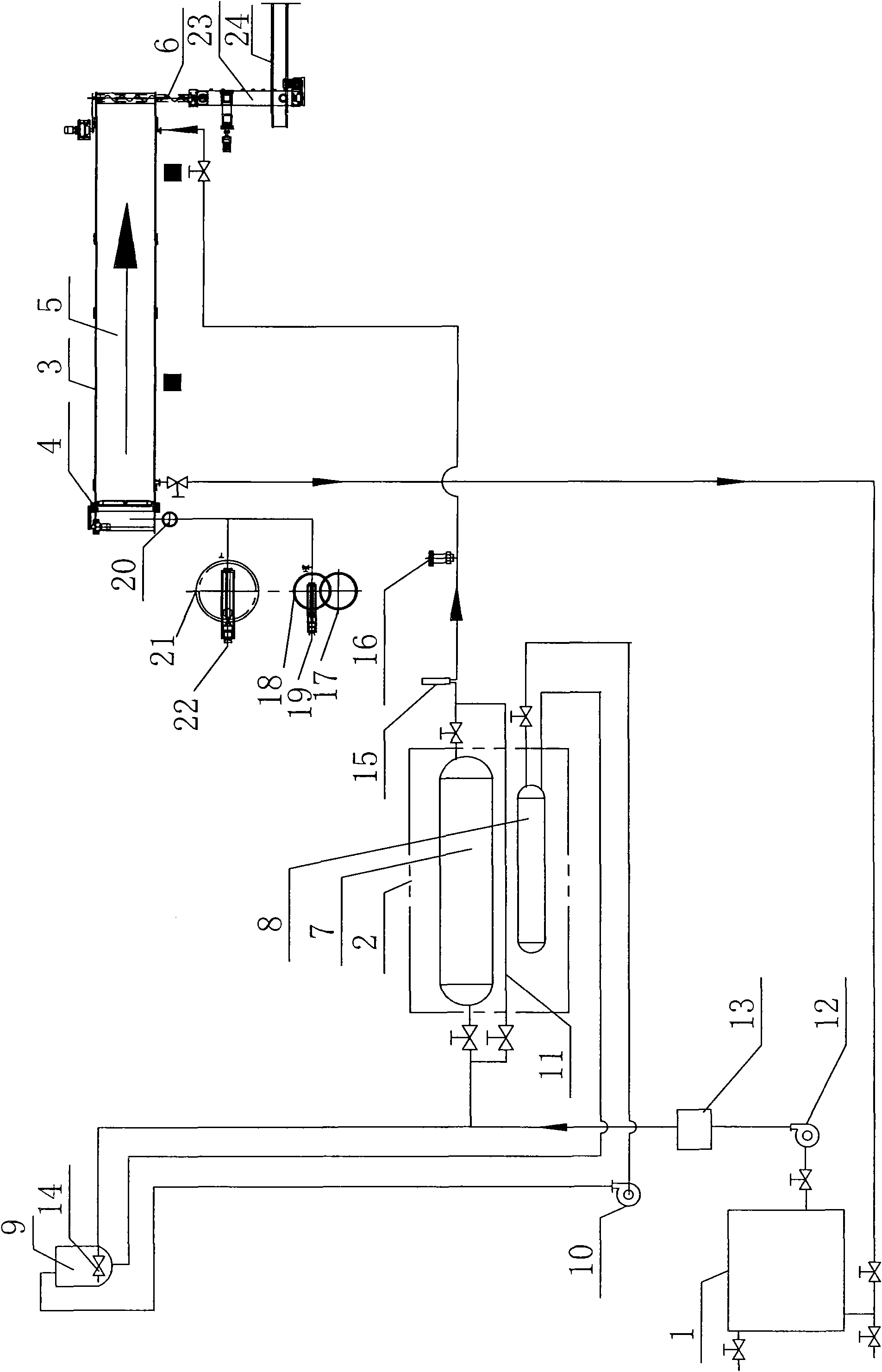

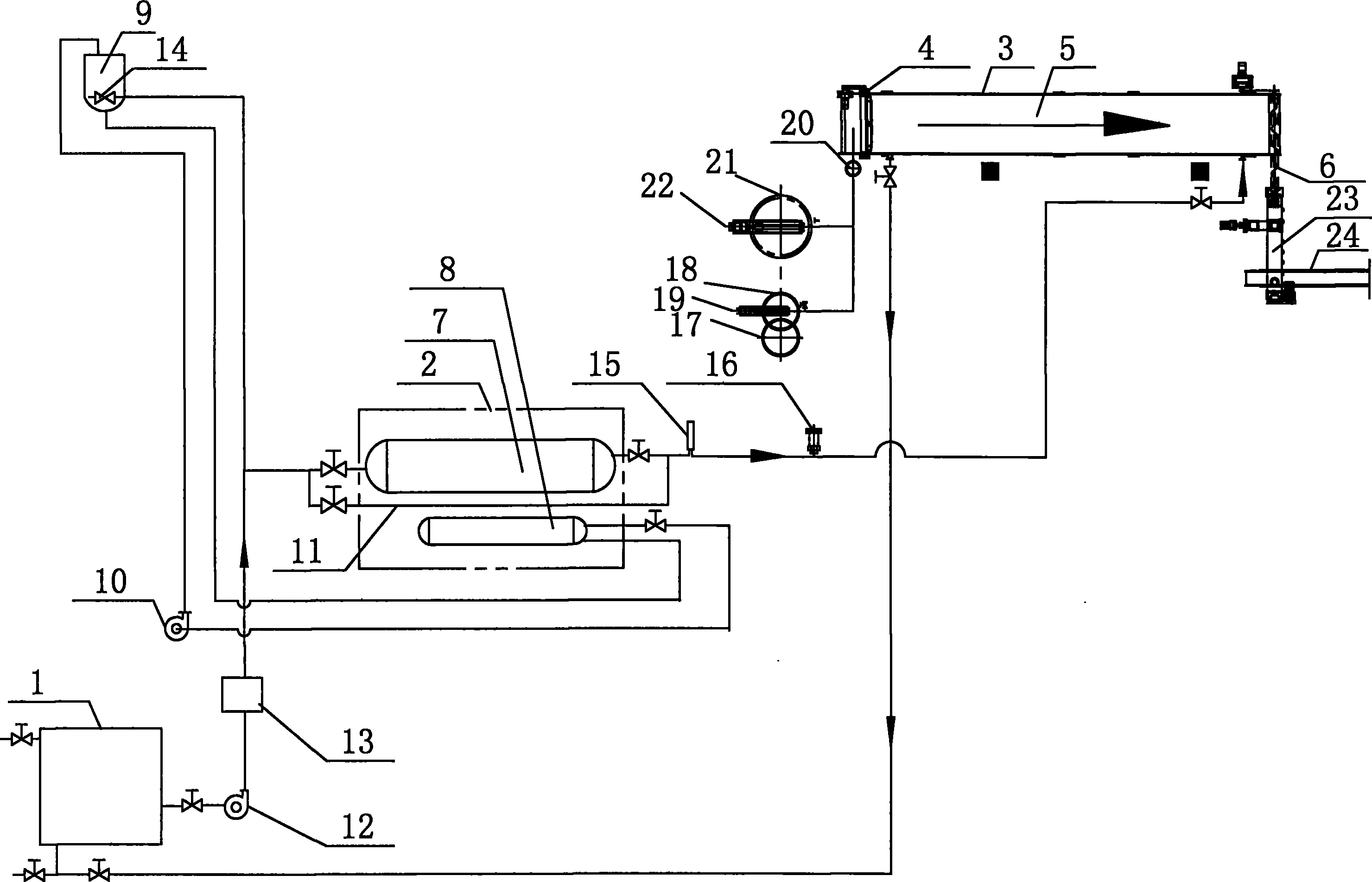

[0018] Such as figure 1 The cooling water temperature self-control circulation system of the emulsion explosive production line shown includes a reservoir 1, a water chiller 2, and a matrix water-immersed direct cooler 3. The entrance of the matrix water-immersed direct cooler 3 is provided with a distributing machine 4, and the distributing machine 4 flattens the matrix. Lay on the conveyor belt 5 of the submerged direct cooler 3, the conveyor belt 5 conveys the substrate forward, and the outlet of the submerged direct cooler 3 is provided with a receiving machine 6; the reservoir 1 is connected to the chiller 2 through a water pipe for water cooling , the chiller unit 2 is connected to the water inlet of the substratum water-immersed direct cooler 3 through water pipes, the direction of water flow in the substratum water-immersed direct cooler 3 is opposite to the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com