Method for measuring clearance in proximity nanometer lithography

A technology of nano-lithography and measurement methods, which is applied in measurement devices, optical devices, instruments, etc., to achieve the effect of improving precision and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

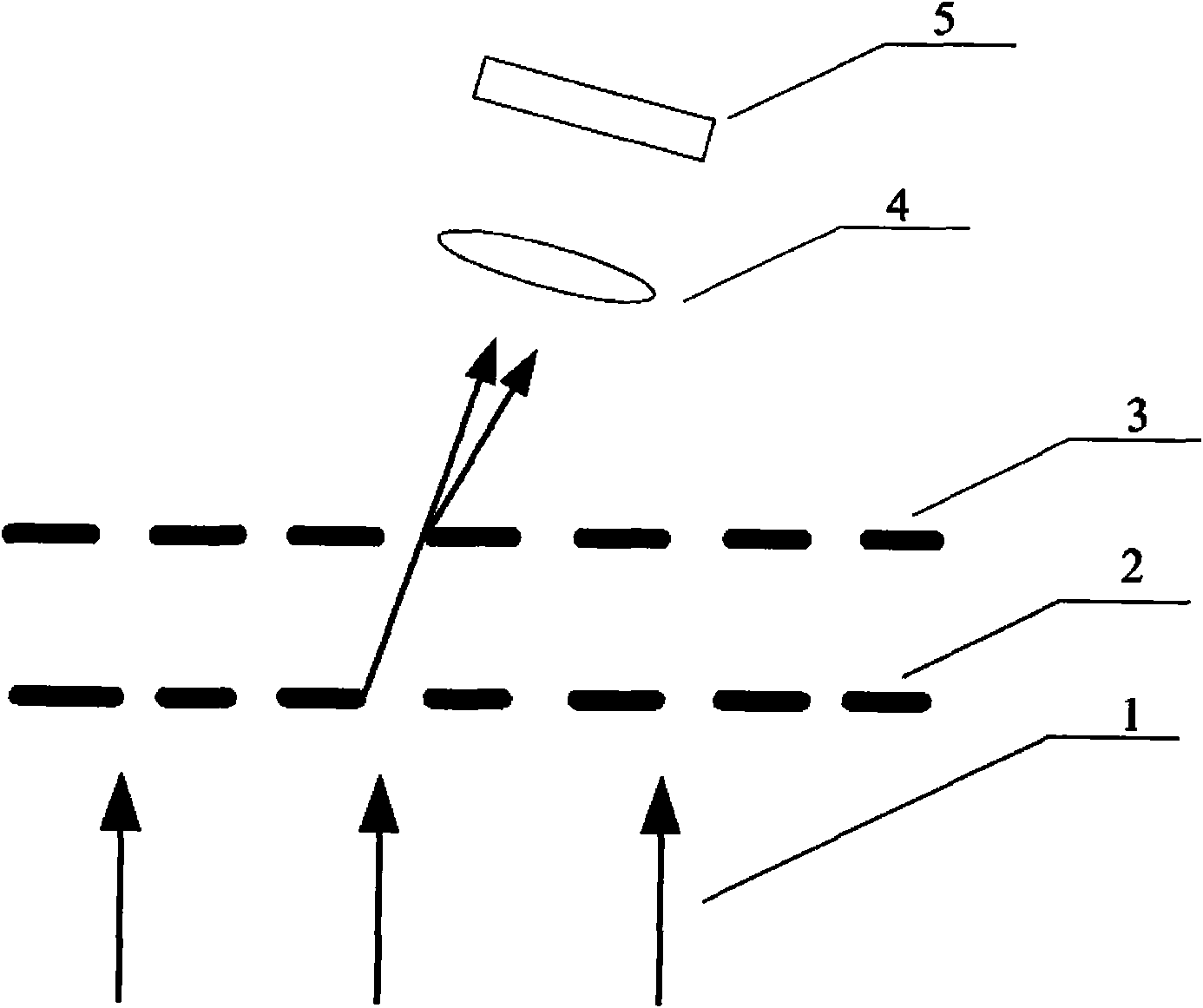

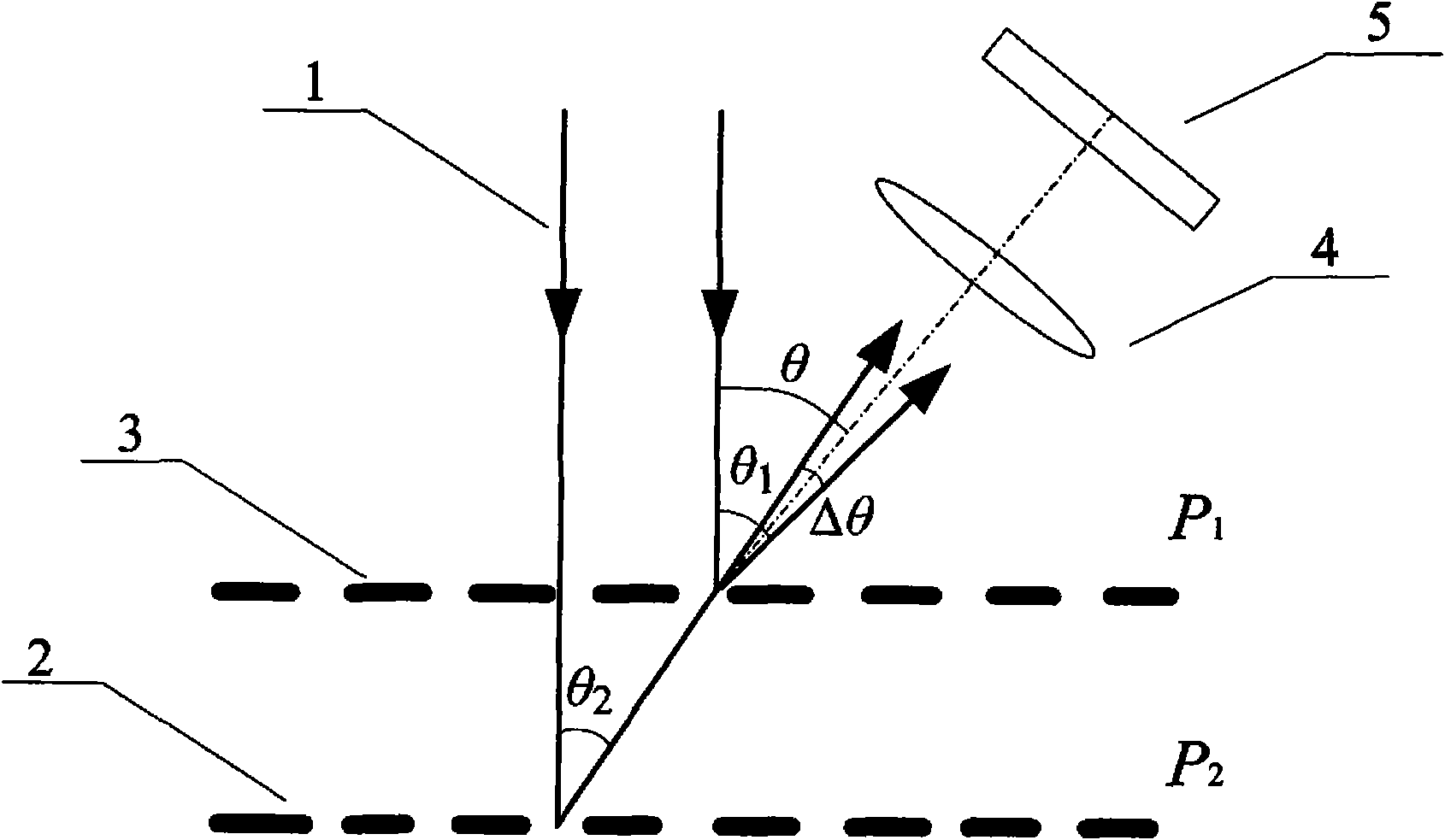

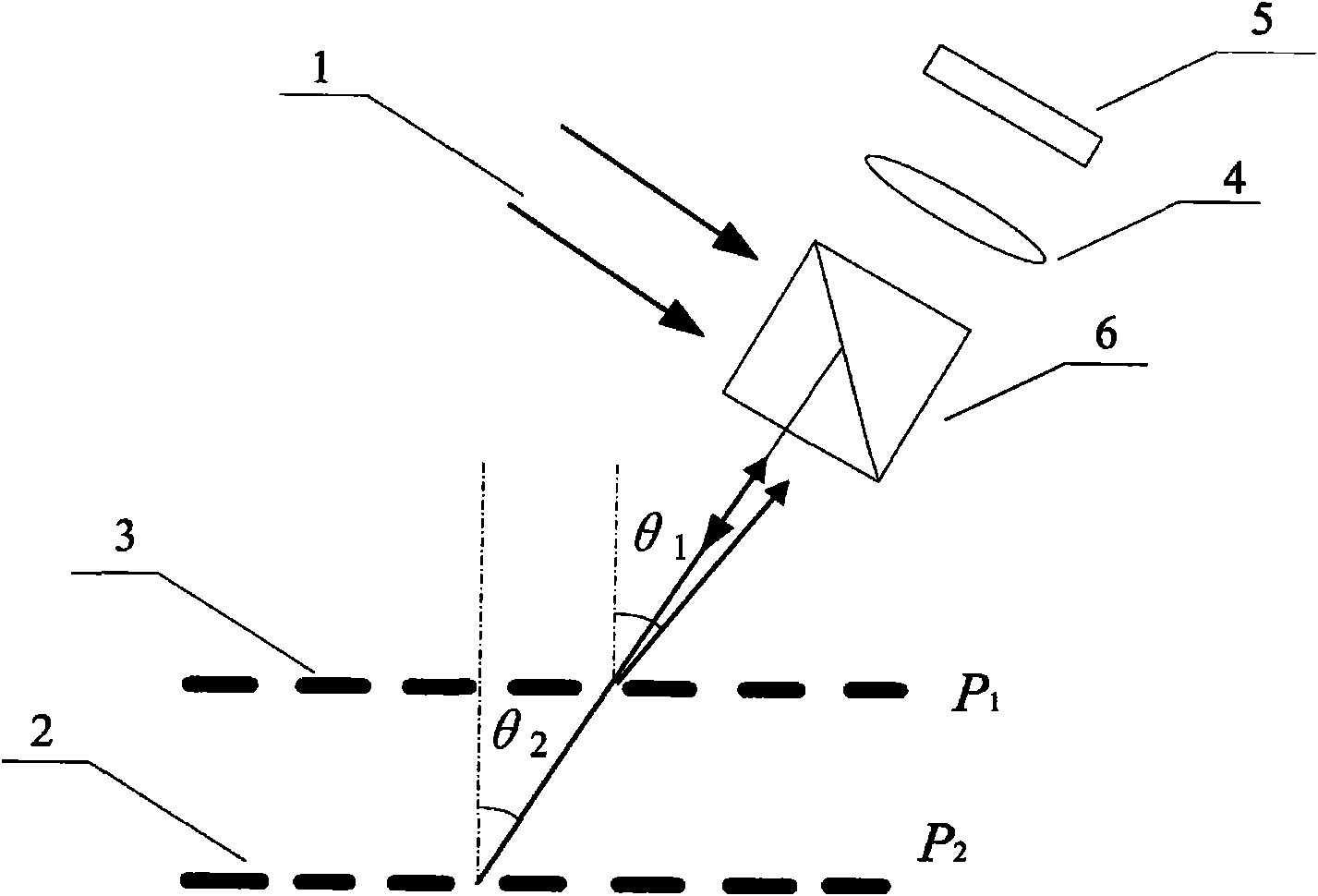

[0036] Such as figure 1 and figure 2 As shown, the gap measurement method applied between the mask and the transparent substrate of the present invention is:

[0037] First, grating 2 and grating 3 are respectively used as marking gratings for gap measurement on the silicon mask. Diffraction occurs on the grating 3. The diffracted lights of the same order from the two gratings (the +1 order is taken as an example in this embodiment, and other orders are similar) meet and interfere on the surface of the mask grating 3, producing interference fringes whose phase can change with the gap. For two beams of +n diffracted light, the interference field strength can be expressed as (maybe let the grating be distributed along the x direction)

[0038]

[0039] Among them, I 1 =a n 2 , I 2 =b n 2 is the intensity of two beams of +n diffracted light, is the initial phase, P=P 1 P 2 / [n(P 2 -P 1 )] is the distribution period of two +n diffracted light interference fringe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com