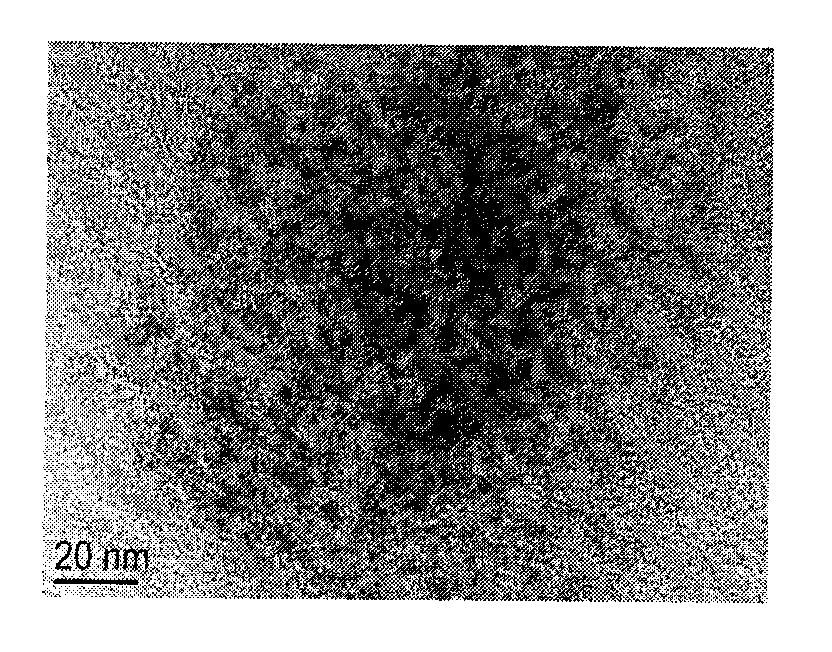

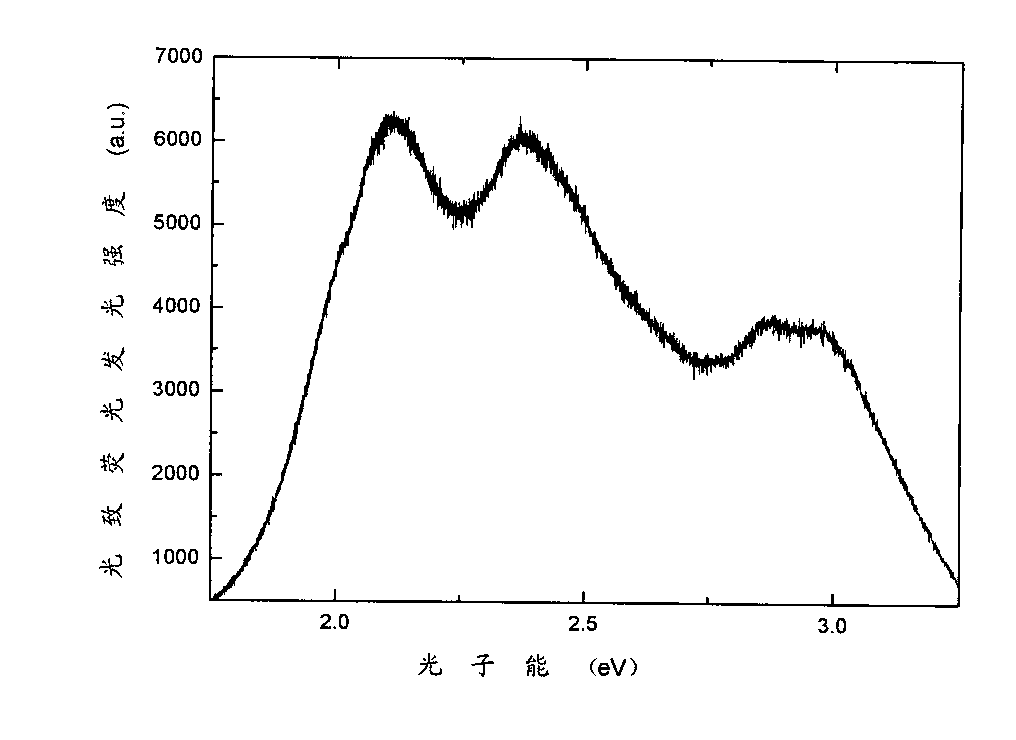

Nanomaterial capable of emitting white fluorescent light and preparation method thereof

A technology of nanomaterials and fluorescence, applied in the preparation of nanomaterials, in the field of nanomaterials, can solve the problems of high cost, complicated preparation process, self-absorption of multi-layer structure, etc., and achieve low cost, simple preparation process and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Weigh 1.05g of zinc acetate and dissolve it in 50mL of hydroalcoholic solution, the volume ratio of water to absolute ethanol is 3:1;

[0025] Second step: 0.735g manganese acetate and 0.499g copper acetate are dissolved in 60mL and 500mL of hydroalcoholic solution respectively, then

[0026] Then take out 0.5mL and 1mL respectively from the manganese acetate solution and the copper acetate solution, and pour them into the zinc acetate solution in (1). At this time, in the prepared mixed solution, the molar ratio of manganese and zinc is about 0.5%, and the molar ratio of copper and zinc is about 0.1%;

[0027] Step 3: Use a magnetic stirrer to vigorously stir the mixed solution prepared above for one hour at room temperature;

[0028] Step 4: Weigh 0.5g of PVP, add it to the mixed solution that has been stirred for one hour, and continue magnetic stirring for one hour. The PVP (polyvinyl pyrrolidone) added in this step is used as a surface modifier, which can...

Embodiment 2

[0034] Step 1: Weigh 1.05g of zinc acetate and dissolve it in 50mL of hydroalcoholic solution, the volume ratio of water to absolute ethanol is 3:1;

[0035] Second step: 0.735g manganese acetate and 0.499g copper acetate are dissolved in 60mL and 500mL of hydroalcoholic solution respectively, then

[0036] Then take out 0.5mL and 1mL respectively from the manganese acetate solution and the copper acetate solution, and pour them into the zinc acetate solution in (1). At this time, in the prepared mixed solution, the molar ratio of manganese and zinc is about 0.5%, and the molar ratio of copper and zinc is about 0.1%;

[0037] Step 3: Use a magnetic stirrer to vigorously stir the mixed solution prepared above for one hour at room temperature;

[0038] Step 4: Weigh 0.5g of PVP, add it to the mixed solution that has been stirred for one hour, and continue magnetic stirring for one hour. The PVP added in this step is used as a surface modifier, which can effectively prevent qua...

Embodiment 3

[0044] Step 1: Weigh 1.05g of zinc acetate and dissolve it in 50mL of hydroalcoholic solution, the volume ratio of water to absolute ethanol is 3:1;

[0045] Second step: 0.735g manganese acetate and 0.499g copper acetate are dissolved in 60mL and 500mL of hydroalcoholic solution respectively, then

[0046] Then take out 0.5mL and 1mL respectively from the manganese acetate solution and the copper acetate solution, and pour them into the zinc acetate solution in (1). At this time, in the prepared mixed solution, the molar ratio of manganese and zinc is about 0.5%, and the molar ratio of copper and zinc is about 0.1%;

[0047] Step 3: Use a magnetic stirrer to vigorously stir the mixed solution prepared above for one hour at room temperature;

[0048] Step 4: Weigh 0.5g of PVP, add it to the mixed solution that has been stirred for one hour, and continue magnetic stirring for one hour. The PVP added in this step is used as a surface modifier, which can effectively prevent qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com