Scale inhibitor for low temperature multiple-effect distillation sea water desalting plants and preparation method thereof

A multi-effect distillation and scale inhibitor technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Poor taste and other problems, to achieve the effect of ensuring safe and stable operation, good drinking taste and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing a scale inhibitor for a low-temperature multi-effect distillation seawater desalination device, and the preparation method includes the following steps:

[0023] A, add the benzotriazole 0.05% of quality level in reactor;

[0024] B, then add 0.05% ethanol of mass grade in reactor, preferably, described ethanol is food-grade alcohol, stir 5~50 minutes while adding and mixing;

[0025] C. Add 35% of mass-grade acrylic acid binary copolymer to the stirred solution, and stir for 5 to 50 minutes;

[0026] D. Add 40% of mass-grade polyacrylic acid and 4.5% of mass-grade hydrolyzed polymaleic acid to the stirred solution, and stir for 10 to 50 minutes;

[0027] E. Add 0.35% of mass-grade phenol polyoxyethylene ether to the stirred solution, and stir for 5 to 50 minutes;

[0028] F. Finally, add the water of the remaining components and stir for 5-50 minutes.

[0029] Thus, the scale inhibitor of the low-temperature multi-effe...

Embodiment 2

[0040] The difference between this embodiment and the above-mentioned embodiment is that the scale inhibitor includes the following components of mass grade: polyacrylic acid 57%, acrylic acid binary copolymer 20%, benzotriazole 0.35%, hydrolyzed polymaleic acid 1%, ethanol 2%, phenol polyoxyethylene ether 0.05%, and the rest is water.

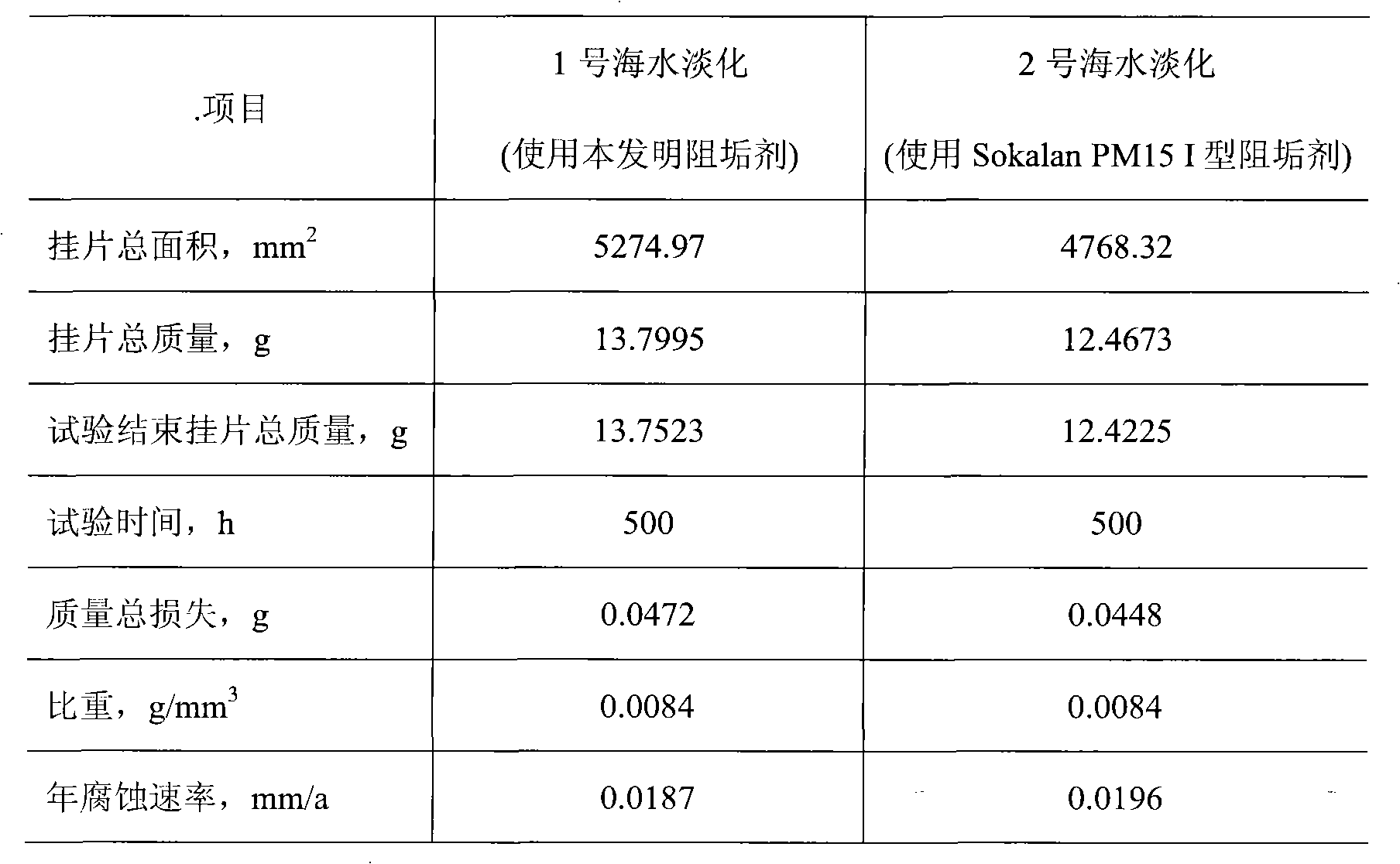

[0041]The corrosion test results of the present embodiment are: when No. 1 seawater desalination uses the scale inhibitor of the present invention to run, the annual corrosion rate of aluminum brass is 0.0189mm / a; when No. 2 seawater desalination uses SokalanPM15 I type scale inhibitor to run , the annual corrosion rate of aluminum brass is 0.0196mm / a. In the corrosion inhibition performance to aluminum brass, the corrosion inhibition performance of the scale inhibitor of the present invention is obviously better than that of Sokalan PM15 type I scale inhibitor.

Embodiment 3

[0043] The difference between this embodiment and the above-mentioned embodiments is that the scale inhibitor of this embodiment includes the following components of mass grade: polyacrylic acid 45%, acrylic acid binary copolymer 28%, benzotriazole 0.15%, hydrolyzed 2.5% polymaleic acid, 1% ethanol, 0.2% phenol polyoxyethylene ether, and the rest is water.

[0044] The corrosion test results of the present embodiment are: when No. 1 seawater desalination uses the scale inhibitor of the present invention to run, the annual corrosion rate of aluminum brass is 0.0186mm / a; when No. 2 seawater desalination uses SokalanPM15 I type scale inhibitor to run , the annual corrosion rate of aluminum brass is 0.0196mm / a. In the corrosion inhibition performance to aluminum brass, the corrosion inhibition performance of the scale inhibitor of the present invention is obviously better than that of Sokalan PM15 type I scale inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com