Driving motor with heat dissipation structure for pure electric vehicle

A pure electric vehicle and heat dissipation structure technology, applied in the field of pure electric vehicle drive motors, can solve problems such as poor heat dissipation capacity, and achieve the effects of increasing surface area, small temperature gradient, and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

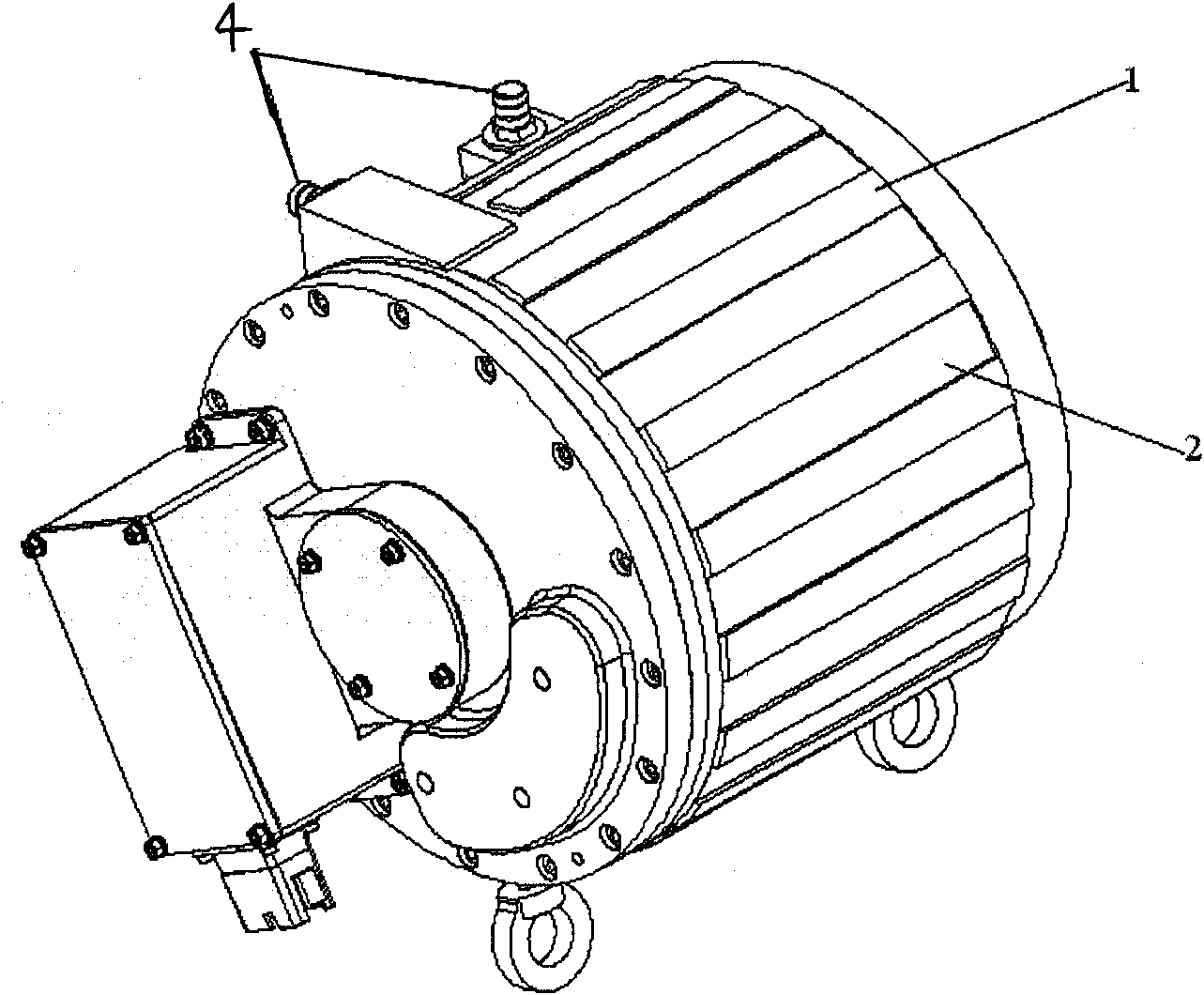

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 1. Distributed with cooling teeth 1 outside the motor housing 2, in order to increase the surface area and improve the heat dissipation capacity, the cooling teeth 1 are in the shape of a cuboid (certainly other shapes can also be taken). A sealing water jacket is installed on the inner side of the motor housing 2, and the water jacket is made of rubber material. When installed, it is integrated with the motor housing 2 and directly pressed on the water channel 3 to play a sealing role.

[0020] see figure 2 , The internal water channel 3 of the motor has a spiral shape and is arranged on the surface of the motor inner shell.

[0021] see image 3 , the structure of the detachable water inlet and outlet nozzle 4 is shown in the figure. combine figure 1 It can be seen that the water inlet and outlet nozzles 4 are distributed at 90°, installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com