Assembly line for second-generation automobile hub unit

A hub unit and assembly line technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as loose parameter control, low production efficiency, and inability to guarantee product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

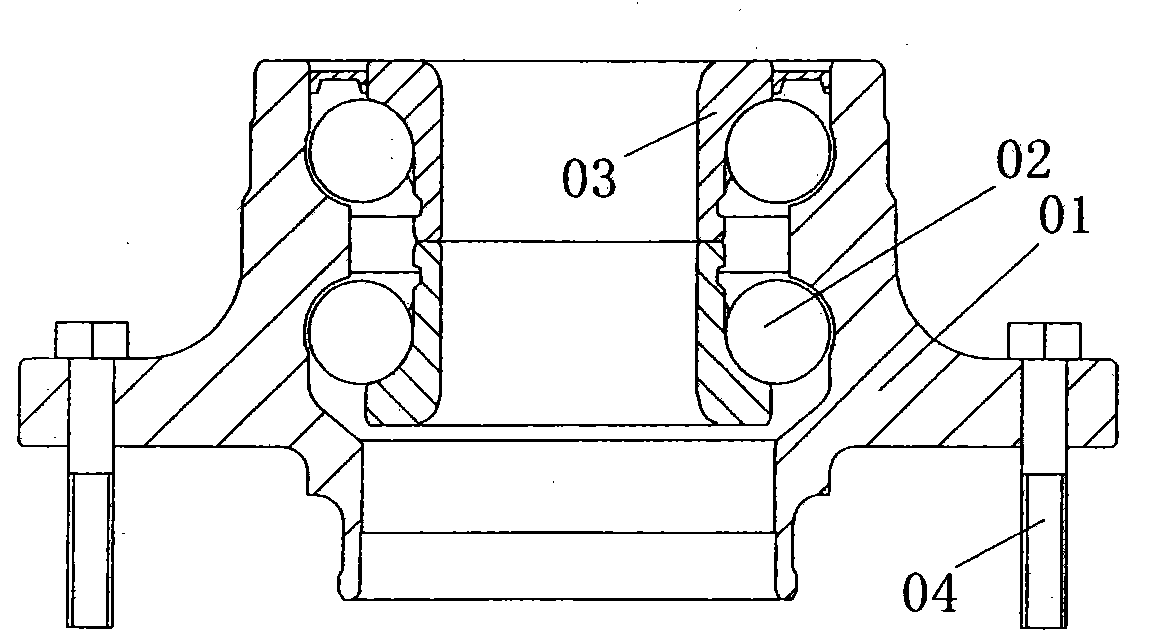

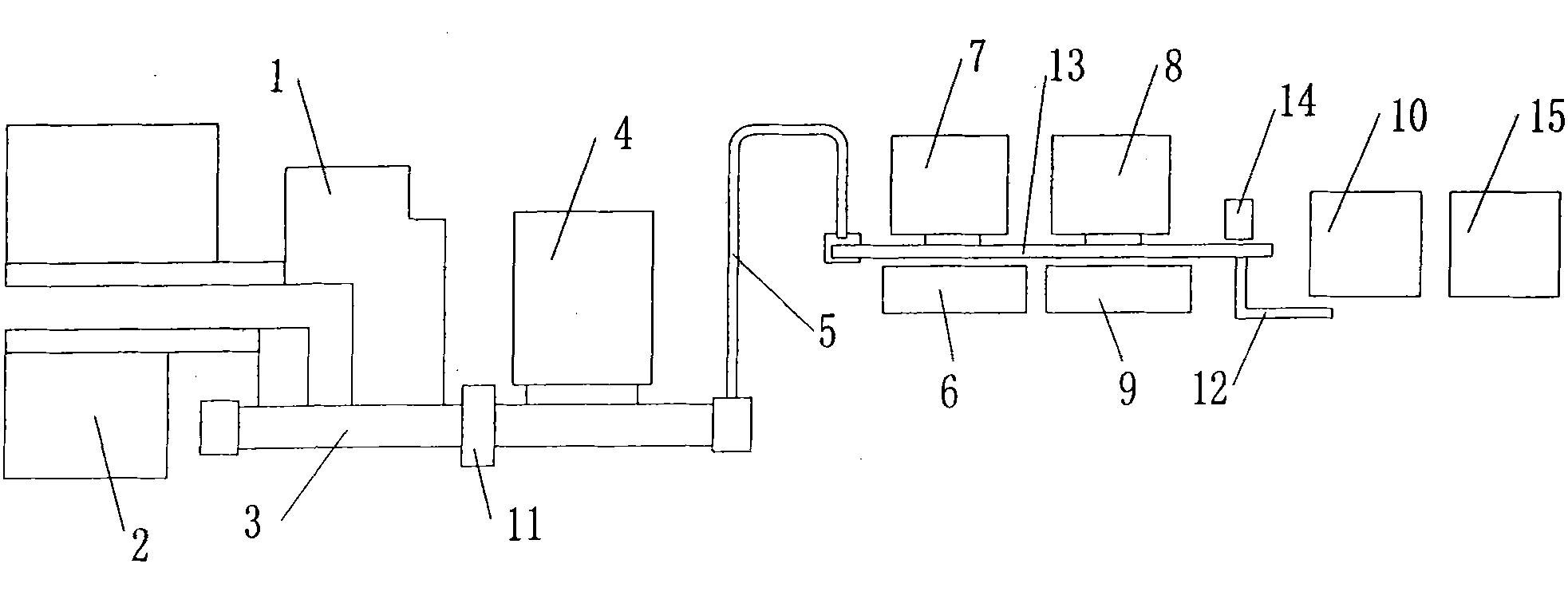

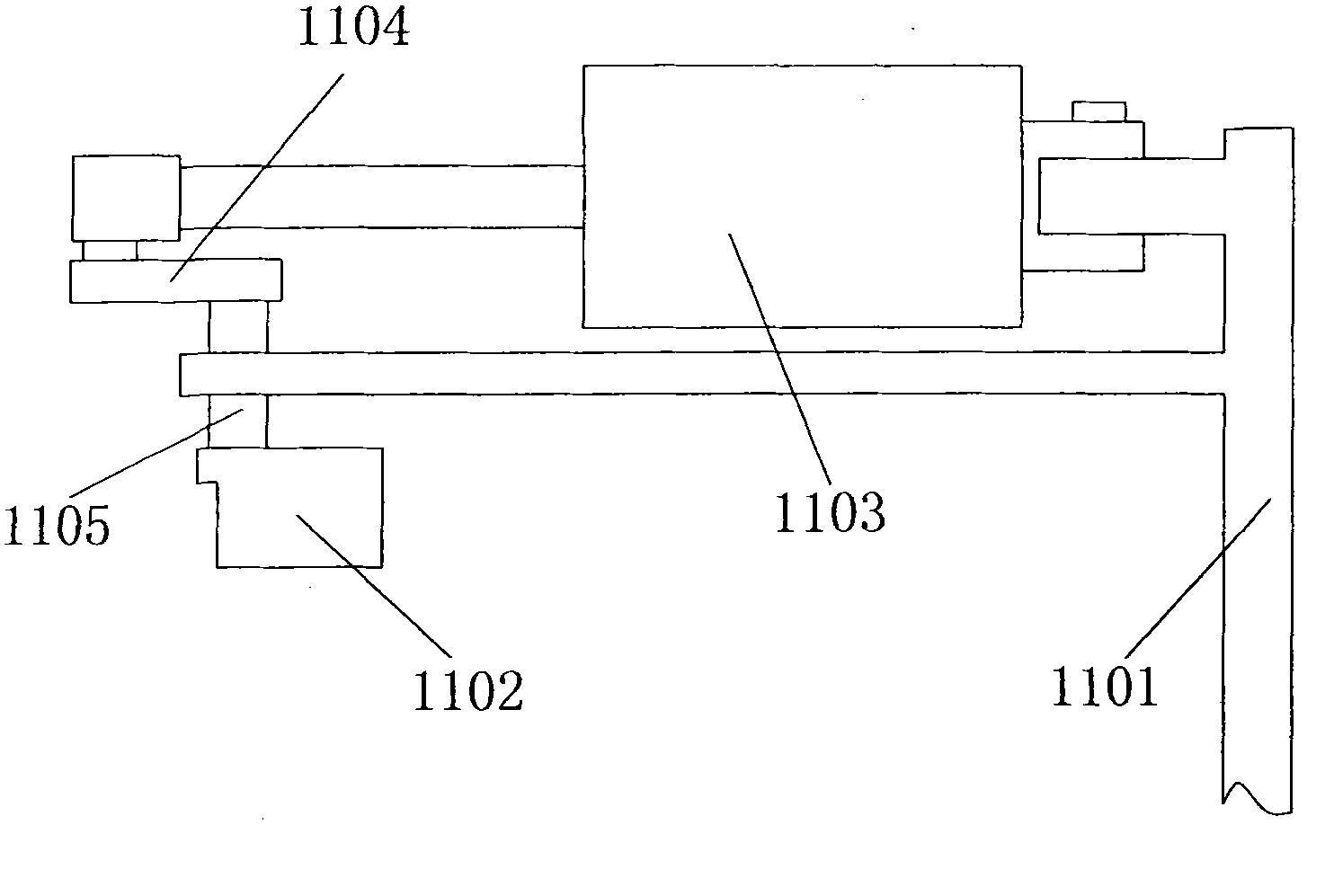

[0117] The overall structural arrangement of the automobile second generation wheel hub unit assembly line of the present invention is as follows: figure 2 As shown, it includes inner ring conveying measuring equipment 1, outer ring conveying measuring equipment 2, pallet conveying line 3, assembly equipment 4, vibration testing equipment 7, clearance testing equipment 8, grease injection testing equipment 10 and bolt pressing equipment 15 . The inner ring conveying measuring equipment 1, the outer ring conveying measuring equipment 2 and the complete set of equipment 2 are connected through a pallet conveying line 3, and the pallet conveying line 3 is provided with a stop and discharge material between the complete set of equipment 2 and the inner ring conveying measuring equipment agency11. The complete set of equipment 7 is connected with the vibration detection equipment 8 through a transmission line 5, and the transmission line 5 is also provided with a blocking and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com