Preparation method of carbon nano tube film

一种碳纳米管膜、碳纳米管的技术,应用在碳纳米管膜的制备领域,能够解决不易形成、胶带与碳纳米管接触不牢固、缝隙等问题,达到避免厚度不均或缝隙的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

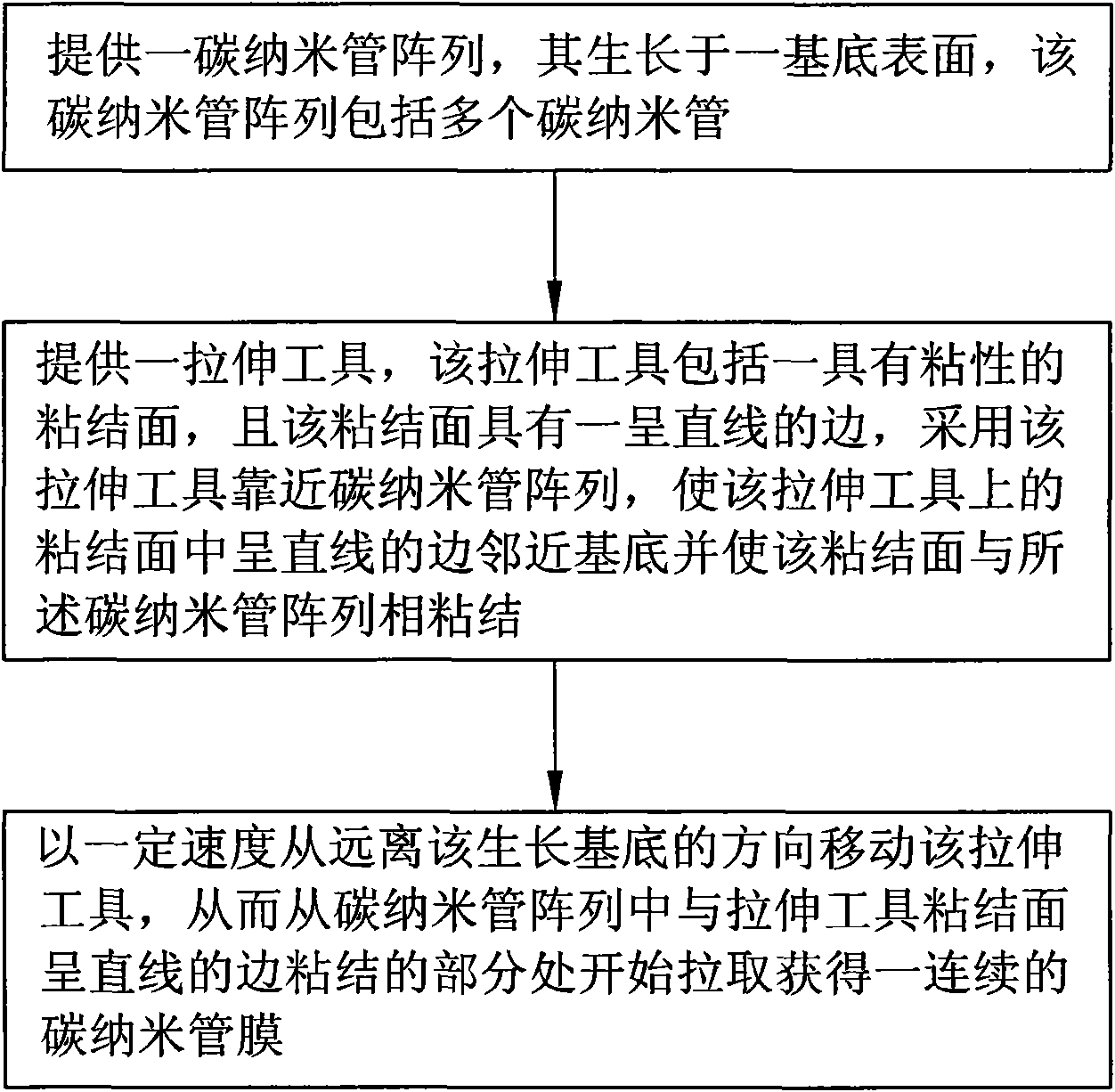

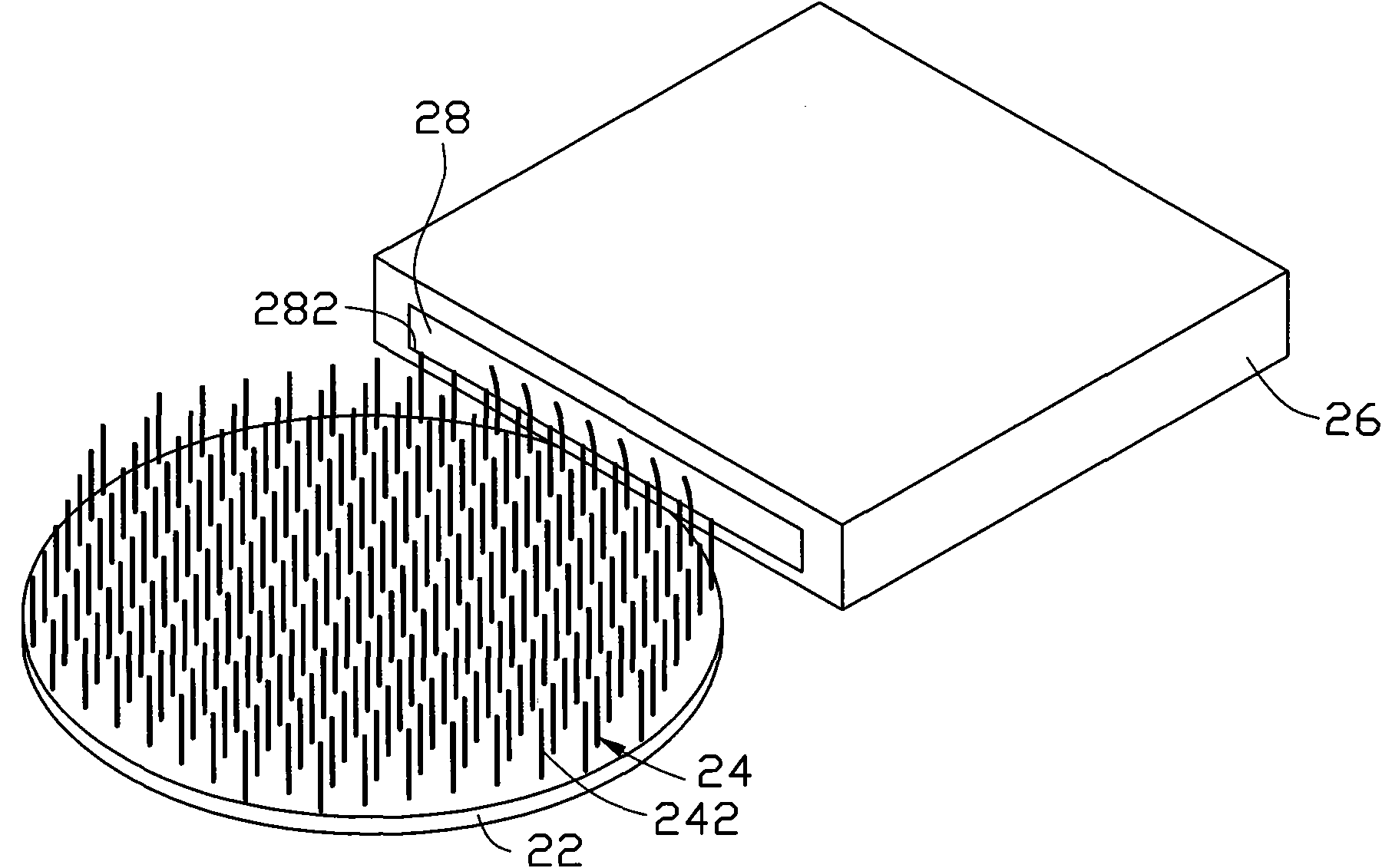

[0017] see figure 2 and image 3 , the preparation method of the carbon nanotube film in the embodiment of the present invention mainly includes the following steps:

[0018] Step 1: providing a carbon nanotube array 24 grown on the surface of a substrate 22 .

[0019] Preferably, in this embodiment, the carbon nanotube array 24 is a super-aligned carbon nanotube array, and the carbon nanotube array 24 is prepared by chemical vapor deposition. The carbon nanotube array 24 is a pure carbon nanotube array formed by a plurality of carbon nanotubes 242 growing parallel to each other and perpendicular to the substrate 22 . The carbon nanotubes 242 in the carbon nanotube array 24 include one or more of single-wall carbon nanotubes, double-wall carbon nanotubes or multi-wall carbon nanotubes. The single-walled carbon nanotubes have a diameter of 0.5 nm to 50 nm, the double-walled carbon nanotubes have a diameter of 1.0 nm to 50 nm, and the multi-walled carbon nanotubes have a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com