Selective hydrogen combustion catalyst for use in internal heating of petroleum hydrocarbon cracking stock and use thereof

A technology of petroleum hydrocarbons and catalysts, applied in the field of hydrogen combustion reaction catalysts, can solve the problems of high consumption of hydrocarbon raw materials, achieve the effects of protecting the environment, saving energy, and improving heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

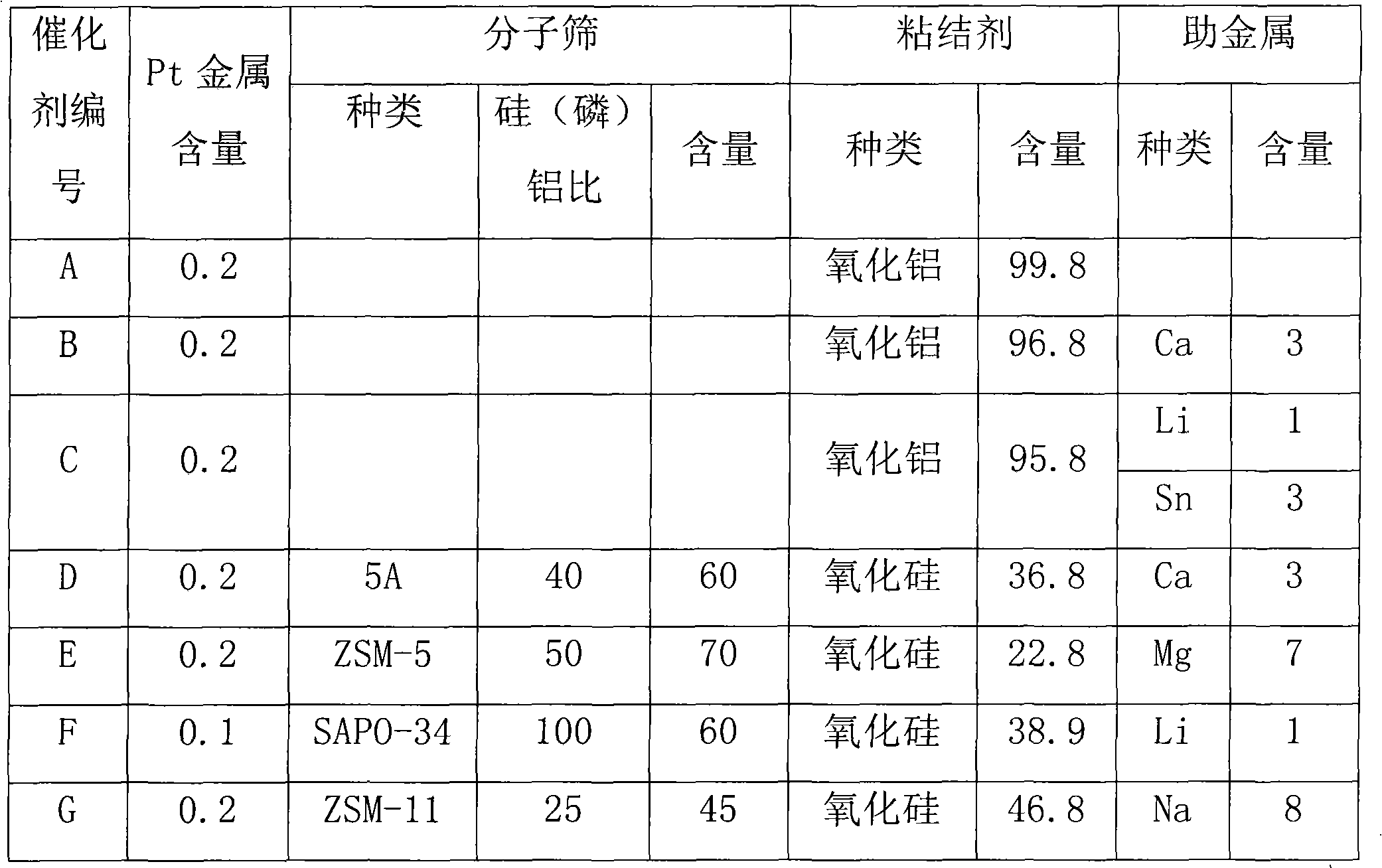

Image

Examples

Embodiment 1

[0046] The preparation method of H-type molecular sieve:

[0047] After the original molecular sieve powder was roasted at 550°C to remove the template agent, the ratio of molecular sieve (g) to exchange solution (ml) was 1:10, and NH 4 NO 3 The solution (0.8mol / L) was exchanged in a 90°C water bath for 5 hours, and filtered; the filter cake was exchanged twice with the same amount of exchange liquid as before, filtered, and washed with distilled water until there was no NO in the filtrate. 3 - Existence, drying at 110°C, and calcining at 550°C to obtain H-type molecular sieves.

Embodiment 2

[0049] The raw powder of 5A molecular sieve was processed according to the preparation method described in Example 1 to obtain type H molecular sieve. The molecular sieve and silicon oxide (specific surface area > 200M 2 / g of high-purity silicon oxide) and safflower powder are mixed in proportion, after mixing, add an appropriate amount of dilute nitric acid, and after mixing, extrude into a cylindrical shape with a diameter of 3mm, dry at 120°C and roast at 550°C to obtain 5A molecular sieve and oxidation. Silicon strips. Take a certain amount of cylindrical particles, and use Ca(NO 3 ) 2 The solution impregnated the particles, separated by filtration, dried at 120°C and calcined at 550°C. The calcined particles were immersed in a solution of hydrochloric acid containing chloroplatinic acid, dried at 120°C after taking out, and treated with air at 450°C for 2 hours to obtain catalyst D.

Embodiment 3

[0051] The ZSM-5 molecular sieve raw powder was processed according to the preparation method described in Example 1 to obtain H-type molecular sieve. According to the method described in Example 2, with Mg(NO 3 ) 2 Solution and solution containing chloroplatinic hydrochloric acid. Mg and Pt are impregnated on the cylindrical strip containing ZSM-5 molecular sieve and silicon oxide to obtain catalyst E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com