Extraction of hydrocarbons from hydrocarbon-containing materials

A technology of hydrocarbon raw materials and raw materials, applied in the direction of biological raw materials, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve problems such as uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

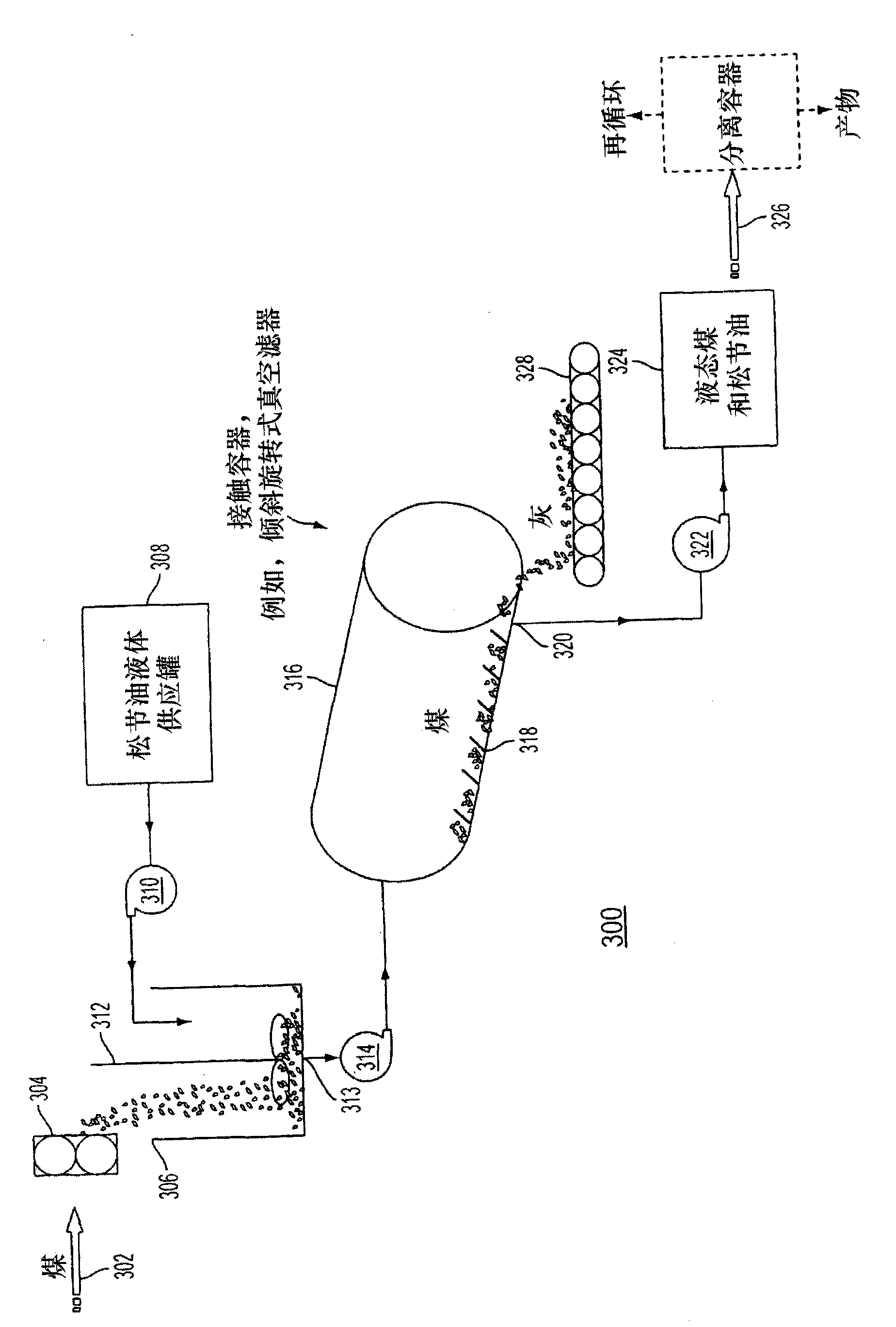

[0051] coal

[0052] In certain embodiments, anthracite or bituminous coal can be comminuted to a size of about 0.841 mm (20 mesh) to about 0.149 mm (100 mesh) and then passed through a 5 Pascal (1atm) ~ about 2.0×10 5 Dissolved and / or extracted, ie liquefied, by immersion in turpentine liquid under pressure in the Pascal (2.0 atm) range. In certain other embodiments, the turpentine liquid may be natural, synthetic or mineral turpentine comprising up to about 50-70% by volume of alpha-terpineol, about 20-40% by volume of beta-terpineol, and About 10% by volume of other components. In certain embodiments, a bed of crushed anthracite or bituminous coal may be stirred through the turpentine liquid at a temperature of 80°C to about 130°C, or possibly up to the boiling point of the turpentine liquid. In certain embodiments, the duration of dissolution and / or extraction, ie, liquefaction, can be from about 10 minutes to about 40 minutes. In certain embodiments, the contact tim...

Embodiment 1

[0104] Example 1. In this example, coal from the Pittsburgh coal seam in Washington County, Pennsylvania was liquefied with the reagent alpha-terpineol. Coal samples were obtained from the Coal Bank of Pennsylvania State University, and the approximate analysis provided by the university is as follows: 2.00 wt.% moisture received, 9.25 wt.% dry ash, 38.63 wt.% dry volatiles and 50.12 wt.% dry fixed carbon. The particle size of the coal sample was about 60 mesh. About 60 grams of alpha-terpineol was gently added to about 30 grams of coal sample placed in the extraction vessel, resulting in a reagent-to-sample ratio of 2:1. The capped but not hermetically sealed extraction vessel containing the resulting mixture of α-terpineol and coal was maintained at a constant temperature of about 96°C with constant agitation. The pressure in the extraction vessel is maintained at slightly below about 1.01 x 10 5 Pascal (1 atm) ambient pressure without boiling α-terpineol. After about 30...

Embodiment 2

[0105] Embodiment 2. This embodiment is almost the same as Embodiment 1, the difference has two aspects. As in Example 1, after maintaining the temperature at about 96°C for about 30 minutes, the extraction vessel containing the coal sample and α-terpineol was held at a temperature of about 135°C for an additional period of about 30 minutes. The pressure in the extraction vessel is maintained at slightly below about 1.01 x 10 5 Pascal (1atm) ambient pressure. The conversion rate of the coal sample, ie the degree of liquefaction, was determined to be about 70 wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com