Light trapping structure for thin film silicon/crystalline silicon heterojunction solar battery

A light trapping structure and solar cell technology, applied in the field of light trapping structure, can solve the problems of difficulty in obtaining high-performance thin-film silicon/crystalline silicon heterojunction solar cells, increasing the difficulty of the heterojunction interface, and reduce the interface state density. The effect of good solar cell performance and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

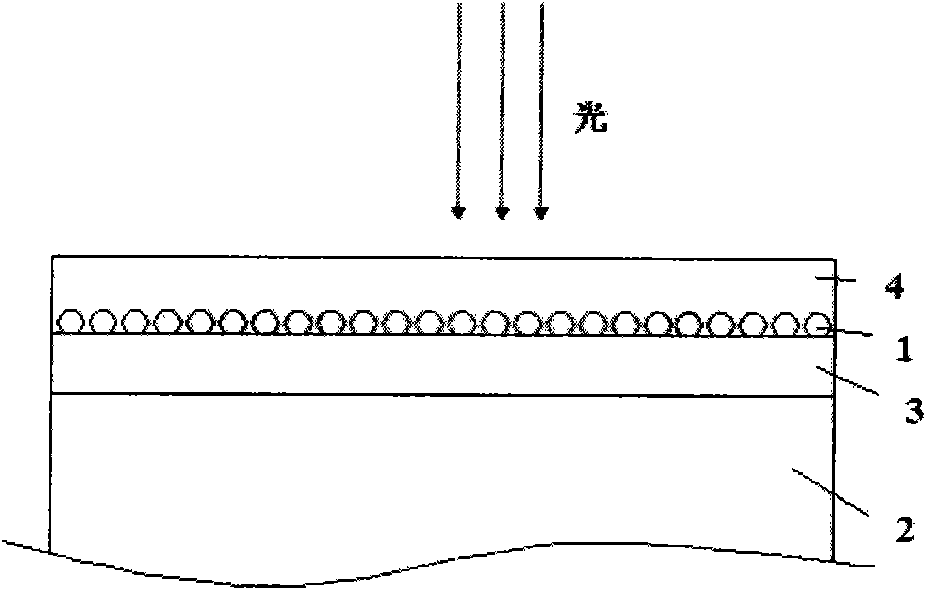

[0037] as attached figure 2 A light-trapping structure for thin-film silicon / crystalline silicon heterojunction solar cells shown, the light-trapping structure includes: a crystalline silicon substrate (2), on the light-facing surface of the crystalline silicon substrate (2) The doped thin film silicon layer (3), the metal nanostructure (1) on the doped thin film silicon layer (3), and the transparent conductive electrode (4) on the metal nanostructure (1); wherein , the light-facing surface of the crystalline silicon substrate (2) is not intentionally woven, and the metal nanostructure (1) is metal nanoparticles.

Embodiment 2

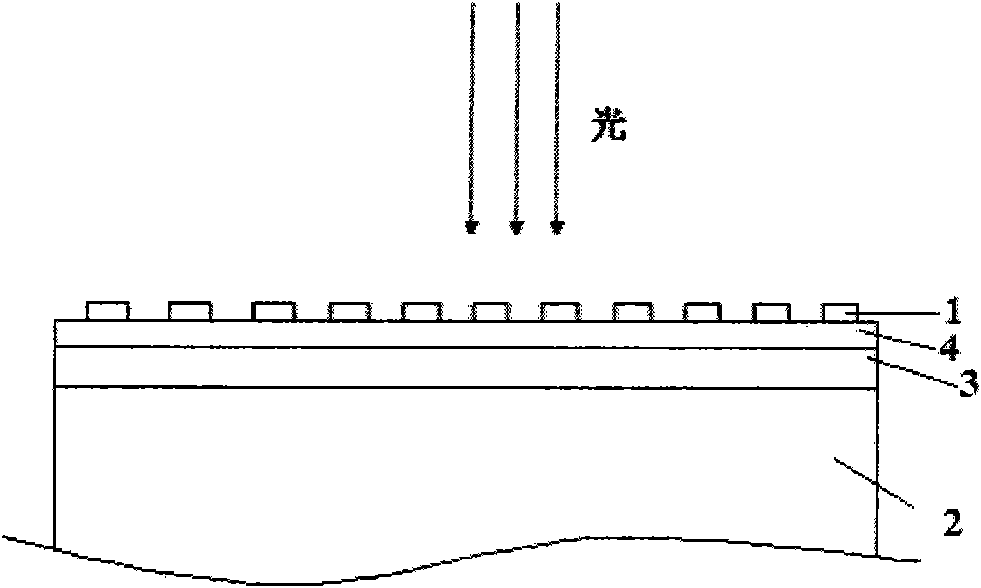

[0039] as attached image 3 A light-trapping structure for thin-film silicon / crystalline silicon heterojunction solar cells shown, the light-trapping structure includes: a crystalline silicon substrate (2), on the light-facing surface of the crystalline silicon substrate (2) The doped thin film silicon layer (3), the transparent conductive electrode (4) on the doped thin film silicon layer (3), and the metal nanostructure (1) on the transparent conductive electrode (4); wherein , the light-facing surface of the crystalline silicon substrate (2) is not intentionally woven, and the metal nanostructure (1) is a metal nanospace network.

Embodiment 3

[0041] as attached Figure 4A light-trapping structure for thin-film silicon / crystalline silicon heterojunction solar cells is shown, the light-trapping structure includes: a crystalline silicon substrate (2), on the backlight surface of the crystalline silicon substrate (2) A doped thin film silicon layer (3), a transparent conductive electrode (4) on the doped thin film silicon layer (3), and a metal nanostructure (1) inside the transparent conductive electrode (4); wherein, The backlight surface of the crystalline silicon substrate (2) is not intentionally woven, and the metal nanostructure (1) is a metal nanodisk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com