Thermal barrier coating layer high-temperature resistance molten salt corrosion test method and device

A technology of molten salt corrosion and thermal barrier coating, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc. The test time is arbitrarily controllable and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

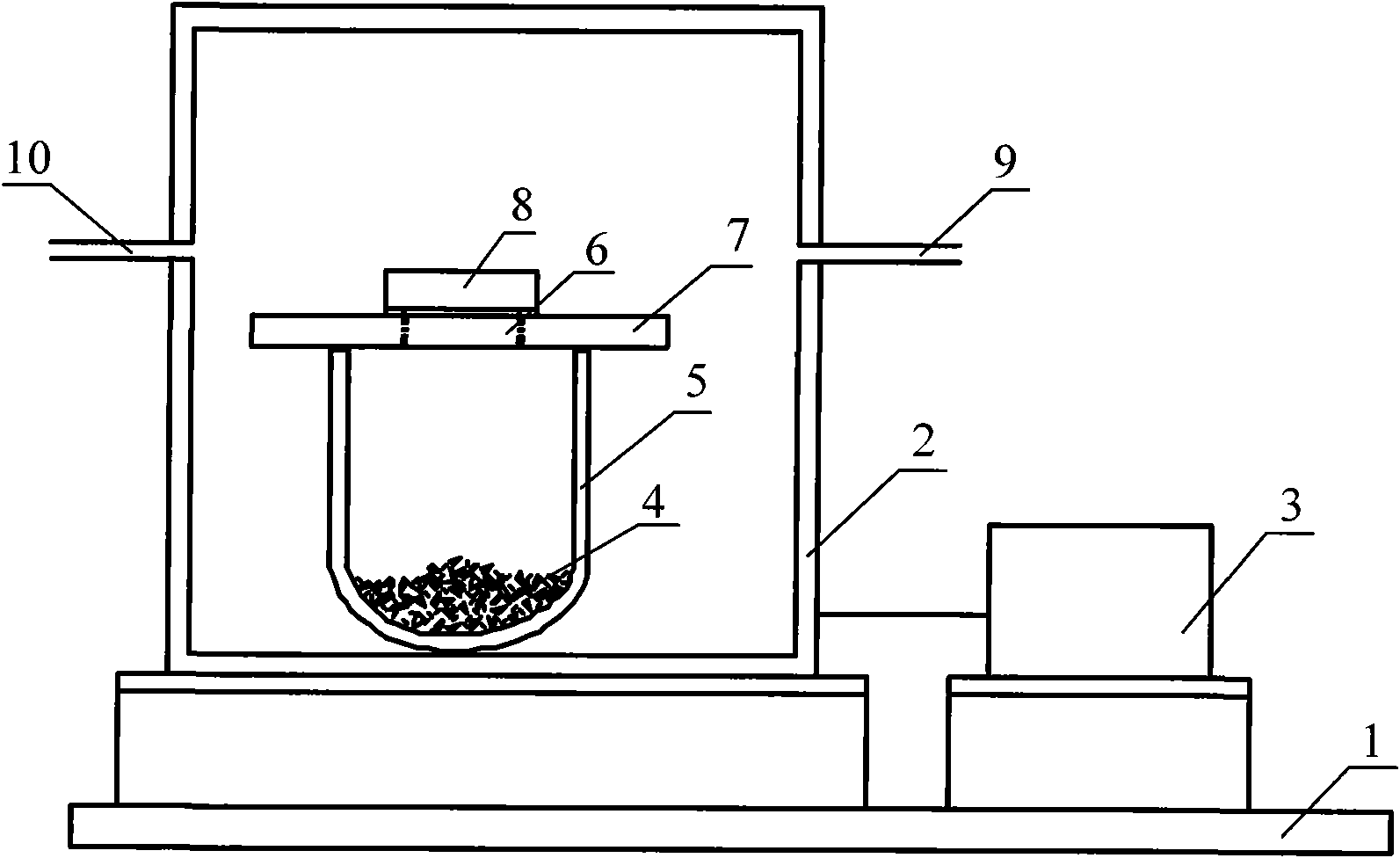

[0025] The working principle of the present invention and the method of use are further described below in conjunction with the accompanying drawings of the embodiments:

[0026] Please refer to the attached figure 1 , this is the test method and device layout of the thermal barrier coating against high temperature molten salt corrosion described in the present invention. On the working platform 1, the closed cavity type heating furnace 2 described in the present invention is set. A crucible 5 with corrosion salt powder 4 is arranged in the heating furnace 2 , and an electric heater controlled by a temperature controller 3 is arranged at the bottom of the crucible 5 .

[0027] The temperature rise and fall and constant temperature control in the heating furnace cavity are realized by the temperature controller 3 connected with the electric heater in the heating furnace 2 . The temperature controller 3 of this embodiment adopts XMT artificial intelligence precision controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com